Industries

Healthcare

Modeling and simulation are proven ways to address the high and unsustainable costs and time required for design and regulatory approval of increasingly complex healthcare solutions. This in silico approach maximizes patient safety while making healthcare more affordable.

Accelerating Innovation in Healthcare With In Silico Medicine

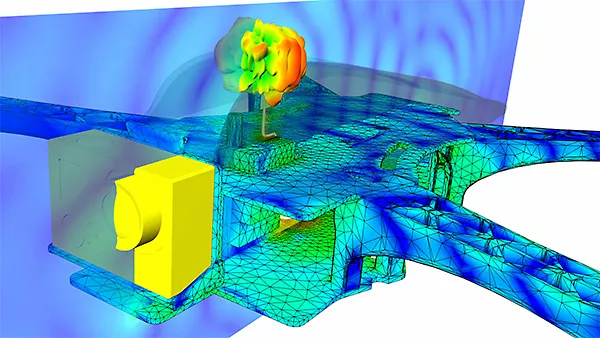

The healthcare industry is at the forefront of advancing medical science, improving patient care, and developing innovative treatment solutions. With the growing demand for precision, reliability, and efficiency in medical devices, drug delivery systems, and treatment methods, simulation tools play a critical role in optimizing designs and ensuring safety. Ansys provides a comprehensive suite of simulation solutions, including Ansys Mechanical for structural analysis, Ansys Fluent for fluid dynamics, Ansys HFSS and Ansys Maxwell for electromagnetic field simulations, Ansys LS-DYNA for impact and durability testing, and Ansys Granta for selection of best materials and materials data management. These tools help healthcare engineers create safer, more effective solutions that improve patient outcomes and drive innovation.

- Medical Devices

- Pharma/Biopharma

- Clinical Applications

Cardiovascular

ANSYS solutions for Cardiovascular applications provide advanced simulation of blood flow, vessel dynamics, and medical device interaction. These tools support the design of safer, more effective treatments and devices for cardiovascular health.

Structural analysis for stents, valves, and other cardiovascular implants to enhance durability and prevent failure.

Fluid dynamics simulations to optimize blood flow in cardiovascular devices, ensuring efficient functioning.

Electromagnetic simulations for pacemakers to ensure safe and reliable operation within the human body.

Thermal analysis to ensure the devices maintain safe operating temperatures during continuous use.

Vibration analysis to enhance device stability and performance, ensuring longevity and patient safety.

Component-Level Capabilities

ANSYS Component-Level Capabilities for Cardiovascular applications enable detailed simulation of stents, valves, catheters, and vascular structures. These tools help optimize device performance, biocompatibility, and durability in real-world physiological conditions.

Stents

- Simulate blood flow to optimize stent design for efficiency and minimal blood turbulence.

- Analyze structural strength to prevent collapse and ensure long-term durability under arterial pressures.

Heart Valves

- Test fluid dynamics to ensure proper valve opening and closing to avoid regurgitation.

- Perform structural fatigue analysis to ensure the valve's long-term functionality under constant cyclic loads.

Pacemakers

- Simulate electromagnetic performance to guarantee reliable operation without interference from external signals.

- Conduct thermal simulations to prevent overheating of the device and ensure long-term safety in the body.

Catheters

- Analyze fluid dynamics to enhance the precision and efficiency of drug or fluid delivery and reduce clotting risks.

- Test structural flexibility to ensure ease of insertion and comfort during patient use.

Relevant Ansys Software

Relevant ANSYS software for Cardiovascular applications includes ANSYS Fluent, Mechanical, and SpaceClaim to simulate blood flow, structural behavior, and device-tissue interaction. These tools enable accurate modeling for innovative and reliable cardiovascular device design.

Ansys Polyflow

Simulates the manufacturing process of polymers used in cardiovascular devices, including stents and artificial heart valves.

Orthopedics

ANSYS solutions for Orthopedics provide advanced simulation of bones, joints, and orthopedic implants to evaluate mechanical performance and biological interaction. These tools help improve implant design, patient safety, and treatment outcomes.

Structural analysis for implants and prosthetics to optimize strength and longevity under various loading conditions.

Vibration and fatigue testing to ensure long-term durability of orthopedic devices under repeated mechanical stresses.

Explicit dynamics to evaluate the response of components due to mechanical shock and impacts.

Component-Level Capabilities

ANSYS Component-Level Capabilities for Orthopedics enable precise simulation of implants, bone structures, and joint mechanics under physiological loads. These tools support the design of durable, biocompatible solutions tailored for improved patient outcomes.

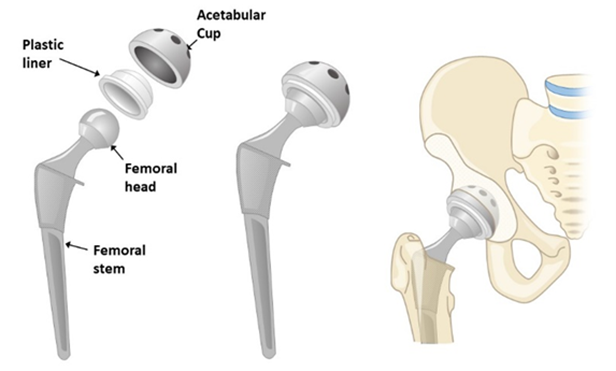

Hip Implants

- Perform structural analysis to optimize load distribution and ensure the implant’s stability and longevity under various loads.

- Conduct fatigue analysis to evaluate the implant’s durability over time under dynamic loads.

Knee and Spinal Implants

- Conduct structural analysis to ensure the implant provides adequate support and stability.

- Evaluate material wear to ensure durability under repetitive use and prevent implant failure.

Artificial Limbs

- Perform structural analysis to model load-bearing capabilities and ensure reliable function during daily activities.

- Conduct kinematic simulations to optimize joint movement and ensure natural motion and comfort.

Orthopedic Braces

- Conduct flexibility and stress analysis to optimize support for injury prevention and enhance recovery.

- Perform fatigue analysis to assess the long-term durability and ensure the brace maintains performance under repeated mechanical stresses.

Relevant Ansys Software

Relevant ANSYS software for Orthopedics includes ANSYS Mechanical, SpaceClaim, and LS-DYNA to simulate structural integrity, implant fit, and impact response. These tools enhance orthopedic device design, performance, and patient-specific customization.

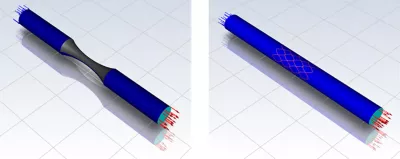

Ansys Composite PrepPost

Ansys Polyflow

Simulates the polymer manufacturing processes used in producing lightweight, durable prosthetic components and implants.

Ansys Composite Cure Simulation

Simulates the curing process of composites, predicting residual stresses and part distortions during manufacturing.

Diagnostics and Personalized Medicine

ANSYS solutions for Diagnostics and Personalized Medicine enable simulation of medical devices, fluid dynamics, and patient-specific models to improve diagnostic accuracy and treatment planning. These tools support the development of tailored healthcare solutions and advanced medical technologies.

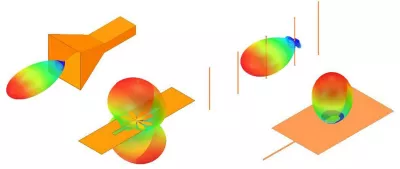

Electromagnetic simulations for medical imaging devices to enhance diagnostic accuracy and reduce operational interference.

Fluid dynamics simulations to optimize contrast agent delivery in imaging systems for improved visualization.

Structural and thermal analysis for diagnostic equipment durability to ensure reliable operation in medical environments.

Component-Level Capabilities

ANSYS Component-Level Capabilities for Diagnostics and Personalized Medicine allow detailed simulation of devices such as biosensors, microfluidics, and diagnostic tools. These solutions enable precision, reliability, and customization for patient-specific healthcare technologies.

MRI Machines and CT Scanners

- Simulate electromagnetic fields for optimal imaging precision and reduce distortion.

- Evaluate acoustic vibrations to minimize noise for patient comfort during imaging sessions.

Ultrasound Devices

- Simulate sound wave propagation for high-resolution imaging of soft tissues and organs.

- Perform structural analysis to evaluate the performance of ultrasound device components under mechanical and thermal loads.

Lab-on-a-Chip Devices

- Simulate fluid dynamics to improve the flow of fluid through the narrow channels of the device.

- Perform structural analysis to assess the mechanical strength and reliability of the device under operational stresses.

Relevant Ansys Software

Relevant ANSYS software for Diagnostics and Personalized Medicine includes ANSYS Fluent, Mechanical, and Discovery to simulate fluid dynamics, structural behavior, and device performance. These tools support the development of accurate, patient-specific diagnostic and therapeutic solutions.

Ansys Discovery

Ansys Granta Selector

Ansys nCode DesignLife

Ansys OptiSLang

Medical and Hospital Supplies

ANSYS solutions for Medical and Hospital Supplies provide advanced simulation tools to optimize the design, performance, and safety of medical devices and consumables. These tools ensure product reliability, regulatory compliance, and improved patient outcomes.

Structural analysis for durability and safety of medical supplies to ensure consistent quality.

Fluid dynamics for optimizing liquid handling and flow control in medical devices.

Electromagnetic simulations for the design of UV disinfecting-equipment and electronic medical devices.

Thermal analysis to maintain safe operating temperatures for various devices and systems.

Component-Level Capabilities

ANSYS Component-Level Capabilities for Medical and Hospital Supplies enable detailed simulation of individual devices such as implants, syringes, and diagnostic tools. These tools ensure optimal performance, durability, and biocompatibility in healthcare applications.

Syringes and Needles

- Test structural strength to ensure reliable performance and prevent breakage during use.

- Perform fluid dynamics simulations to optimize the flow of medication and ensure consistent delivery through the needle.

IV Catheters

- Simulate fluid dynamics for efficient drug delivery under varied conditions.

- Evaluate flexibility and stresses to ensure patient comfort and minimize complications.

UV Disinfecting Equipment

- Simulate electromagnetic performance of the device for effective disinfection.

- Perform thermal analysis to ensure safe and consistent operation during cycles.

Blood Pressure Monitors

- Perform structural analysis to ensure the reliability of components under mechanical stresses during use.

- Simulate fluid dynamics to analyze the pressure distribution and flow characteristics within the cuff and tubes.

Relevant Ansys Software

Relevant ANSYS software for Medical and Hospital Supplies includes ANSYS Mechanical, Fluent, and SpaceClaim to simulate structural integrity, fluid dynamics, and product design. These tools help optimize device functionality, safety, and regulatory compliance in healthcare environments.

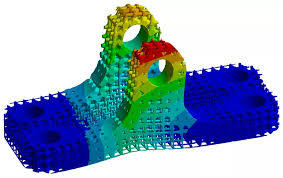

Ansys Additive Suite

Simulates additive manufacturing processes to ensure 3D-printed medical devices meet performance standards for structure and thermal properties.

Ansys Polyflow

Simulates polymer processing, useful for designing lightweight and durable polymer-based medical components.

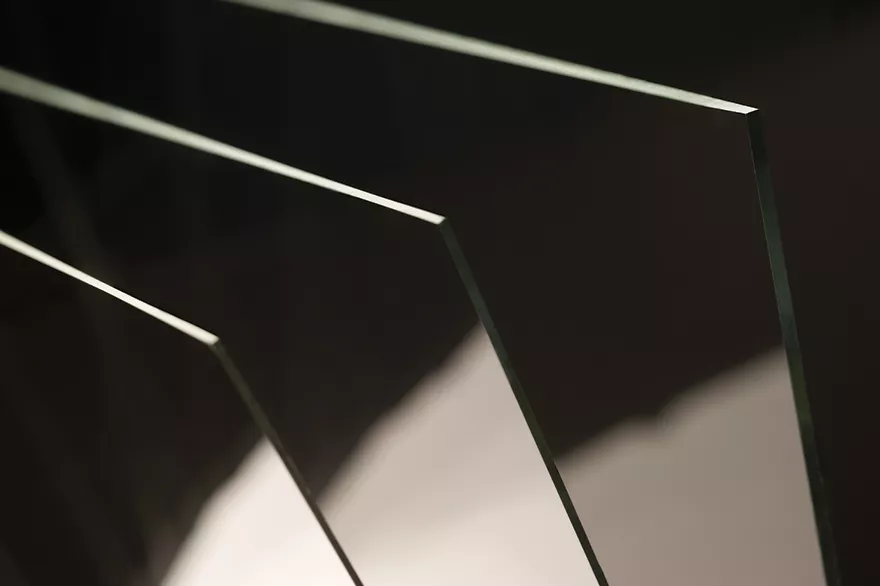

Ansys Composite PrepPost

Used for analyzing composite materials in medical devices, ensuring they meet strength and durability requirements for implants and prosthetics.

Ansys Composite Cure Simulation

Simulates the curing process of composite materials, ensuring that parts such as medical device enclosures or structural components meet specifications.

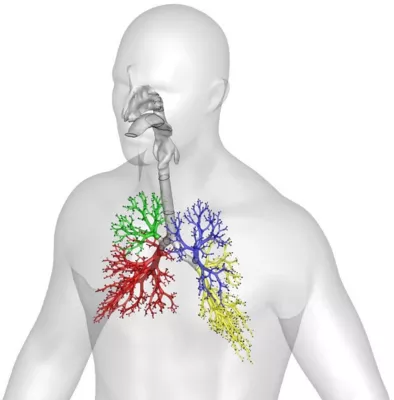

Fluid Dynamics in Drug Delivery Systems

ANSYS solutions for Fluid Dynamics in Drug Delivery Systems simulate fluid flow and interaction within delivery mechanisms like injectors, pumps, and capsules. These tools optimize the efficiency, precision, and effectiveness of drug delivery, enhancing therapeutic outcomes.

Fluid dynamics simulation to enhance the efficiency and accuracy of drug delivery mechanisms.

Structural analysis of devices to ensure reliable operation under varying loads.

Thermal analysis to preserve drug stability during storage and administration.

Component-Level Capabilities

ANSYS Component-Level Capabilities for Fluid Dynamics in Drug Delivery Systems enable detailed simulation of individual components like microfluidic channels, pumps, and reservoirs. These tools optimize flow characteristics, enhance precision, and improve the overall effectiveness of drug delivery devices.

Inhalers

- Simulate fluid dynamics of mixing drug and air to ensure accurate delivery to the respiratory system.

- Perform structural analysis to ensure the canister can withstand the high pressure of the drug inside it.

Infusion and Syringe Pumps

- Simulate flow dynamics to ensure accurate and effective drug administration.

- Evaluate the structural strength of the pump components to withstand operational loads.

Transdermal Patches

- Perform structural analysis to simulate the performance of adhesives under varying environmental conditions to ensure proper adhesion.

Nebulizers

- Simulate fluid dynamics of atomization of the drug to ensure effective medication delivery.

- Perform acoustic analysis to evaluate sound levels and vibrations generated during nebulizer operation, ensuring patient comfort.

Relevant Ansys Software

Relevant ANSYS software for Fluid Dynamics in Drug Delivery Systems includes ANSYS Fluent and CFX to simulate fluid flow, mixing, and pressure in delivery systems. These tools ensure optimized performance, accurate dosing, and enhanced drug delivery efficiency.

Ansys nCode DesignLife

Evaluates the fatigue life and long-term reliability of moving parts in reusable drug delivery systems, such as mechanical pumps and spring mechanisms.

Ansys Polyflow

Models polymer extrusion and blow moulding processes, enabling the design and manufacturing of disposable components like syringes and catheter tubing used in drug delivery systems.

Ansys Additive Suite

Simulates 3D printing processes to ensure reliability and precision of parts in drug delivery devices, such as inhalers or injectors.

interested in our Product or Solution

Still have a Question?

FAQ

How is ANSYS software used in the healthcare industry?

ANSYS enables the simulation of medical devices, implants, and biological systems to ensure safety, reliability, and performance before clinical trials or manufacturing.

What kinds of medical products can be tested using ANSYS?

ANSYS supports simulation for devices like stents, prosthetics, surgical instruments, drug delivery systems, diagnostic equipment, and wearable health tech.

Can ANSYS help meet regulatory compliance for medical devices?

Yes, ANSYS simulations assist in generating data and reports that align with FDA, CE, and other regulatory requirements, helping reduce the time and cost of certification.

Does ANSYS support biomechanical and fluid dynamics simulations?

Absolutely. ANSYS can simulate blood flow, tissue interaction, and biomechanical behavior to optimize design for comfort, functionality, and longevity.

How does ANSYS accelerate innovation in healthcare?

By enabling virtual prototyping, multi-physics simulation, and design optimization, ANSYS shortens development cycles, reduces testing costs, and drives faster, safer innovation.

Transform Ideas into Reality—Explore Our Simulation Solutions Today!

Partner with Us to Revolutionize Engineering Excellence!

Testimonials

Customer Testimonials

Bengal Industries Pvt. Ltd

The ANSYS Mechanical training conducted by Qantur Technologies was highly informative and helped our engineers resolve critical challenges in contact modeling, meshing, and fatigue analysis. The sessions were well-coordinated, delivered on schedule, and supported with patient guidance by the trainer and account manager. We truly value Qantur’s expertise, professionalism, and post-sales support.

Bengal Industries Pvt. Ltd

Bliss Anand Pvt. Ltd.

During our evaluation of CFD solutions, Qantur Technologies stood out for their technical expertise, reliability, and customer-focused approach. Their consulting projects achieved 98% accuracy compared to experimental values, instilling strong confidence in their capabilities. Based on this experience, we selected them as our preferred partner for ANSYS software, consulting, training, and support. We highly recommend their services to organizations with simulation requirements.

Bliss Anand Pvt. Ltd.

CUET, Department of Mechanical Engineering

We experienced significant value from Qantur Technologies’ expertise in ANSYS solutions, particularly in FEA and CFD consulting. Their skilled engineers provided insightful training on geometry, meshing, and modeling, which enhanced our students’ and faculty’s analytical skills. With exceptional support and patience from their trainers, we are pleased to recommend Qantur Technologies for ANSYS implementation, training, and advanced simulation services.

CUET, Department of Mechanical Engineering

Entecnia Consulting Pvt. Ltd.

Our collaboration with Qantur Technologies for ANSYS implementation and consulting has been outstanding. Their commitment, technical expertise, and timely support in FEA and CFD have added significant value to our engineering and R&D teams. The exclusive 15-day training session further enhanced our team’s analytical skills, and we truly appreciate their professionalism and ownership in managing the entire process seamlessly. We highly recommend Qantur Technologies for advanced CAE solutions.

Entecnia Consulting Pvt. Ltd.

Flovel Energy Pvt. Ltd.

Our experience with Qantur Technologies in implementing ANSYS HPC and CFD solutions has been remarkable. Their skilled engineers conducted in-depth training for our R&D team, equipping us with advanced methods to simulate hydro turbines and enhance component performance. Their reliable support, technical expertise, and resource assistance make them a trusted partner for ANSYS software, consulting, and training. We highly recommend Qantur Technologies for any ANSYS-related services.

Flovel Energy Pvt. Ltd.

Flovel Energy Pvt. Ltd.

We truly value the ANSYS SpaceClaim training conducted by Qantur Technologies at our R&D center. The course was tailored to our requirements, highly informative, and supported by hands-on workshops that enhanced our team’s modeling skills. Their application engineer was proactive, helpful, and ensured customization aligned with our needs. We look forward to engaging Qantur Technologies again for future application-based trainings.

Flovel Energy Pvt. Ltd.

IoTechWorld Avigation Pvt. Ltd.

At IoTechWorld, we develop advanced drones for agriculture, survey, and surveillance, and ANSYS Mechanical & CFD have been instrumental in optimizing our designs. Qantur Technologies supported us with the right resources, training, and technical expertise to address complex FEA & CFD challenges. Their team’s commitment and knowledge have empowered us to innovate faster and more effectively. We highly recommend Qantur Technologies for ANSYS implementation, consulting, and support.

IoTechWorld Avigation Pvt. Ltd.

Karman Drones Pvt. Ltd.

Our collaboration with Qantur Technologies for At Karman Drones, innovation drives our mission in AI-powered autonomous drones. Qantur Technologies has been a key partner in implementing ANSYS software, providing outstanding FEA & CFD expertise, consulting, and hands-on training. Their engineers have empowered our team with advanced simulation knowledge, improving design validation, performance optimization, and overall efficiency. We highly recommend Qantur Technologies for their exceptional support and technical proficiency.

Karman Drones Pvt. Ltd.

Mittal Electronics

At Mittal Electronics, innovation and R&D are at the heart of our product development. Partnering with Qantur Technologies for ANSYS FEA & CFD has been transformative—helping us accelerate design validation, optimize performance, and tackle complex engineering challenges with confidence. Their expert training, consulting, and quick response have greatly strengthened our engineering capabilities. We look forward to continued collaboration with Qantur Technologies.

Mittal Electronics

MV Electrosystems Pvt. Ltd.

At MV Electrosystems, innovation in rail transportation demands precision and reliability. Partnering with Qantur Technologies for ANSYS ICEPAK & Mechanical has significantly enhanced our ability to optimize product design, improve efficiency, and accelerate development. Their expert training, technical guidance, and hands-on support in FEA & CFD not only strengthened our engineering skills but also deepened our understanding of core physics. We truly value this collaboration and highly recommend Qantur Technologies for simulation-driven innovation.

MV Electrosystems Pvt. Ltd.

Nicotra India Pvt. Ltd.

At Nicotra India, precision in fan design is critical. Qantur Technologies has been a valuable partner, providing quick and responsive CFD support—both onsite and online—that helped us validate designs and solve complex meshing and model setup challenges. Their extensive training sessions empowered our R&D team with practical simulation expertise, strengthening our analytical and design capabilities. We are pleased with their services and highly recommend them for ANSYS implementation and technical support.

Nicotra India Pvt. Ltd.

NTF (India) Pvt. Ltd.

At NTF India, we rely on advanced engineering solutions to deliver world-class automotive components. Qantur Technologies has been a trusted partner, supporting us with ANSYS implementation and in-depth FEA analysis for our key projects. Their professionalism, technical expertise, and ability to deliver under challenging conditions have consistently exceeded our expectations. We highly value their commitment and look forward to continued collaboration on future product development initiatives.

NTF (India) Pvt. Ltd.

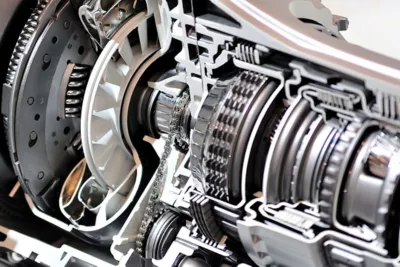

Onassis Auto Limited

At Onassis Auto, precision and reliability are at the core of our automotive components. With Qantur Technologies’ guidance in Ansys Mechanical, we have successfully enhanced our engineering capabilities, optimized transmission components, and improved efficiency. Their hands-on training, prompt support, and expertise in FEA have greatly empowered our R&D team. We are pleased to recommend Qantur Technologies for their outstanding technical services and commitment.

Onassis Auto Limited

P2P Analysis & Solutions

At P2P Analysis & Solutions, innovation is our core, and Qantur Technologies has been an invaluable partner in this journey. Their technical excellence in Ansys Mechanical and LS-DYNA, coupled with meticulous training and proactive support, has empowered our team to solve complex challenges with confidence. Their professionalism, collaborative approach, and customer-centric commitment make them a trusted long-term partner. We strongly recommend Qantur Technologies for any Ansys-related solutions and services.

P2P Analysis & Solutions

S&O Marintime

S&O Marintime