Products

LS-DYNA

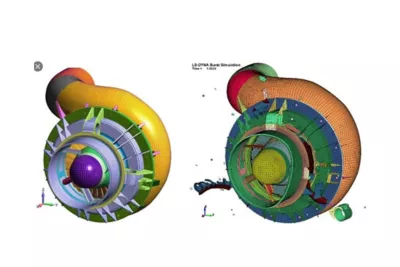

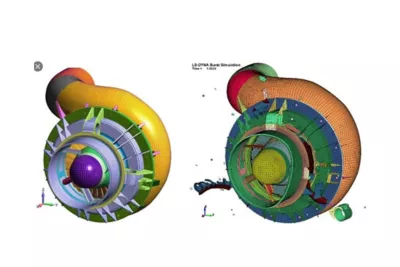

LS-DYNA is the industry-leading explicit simulation software used for applications like drop tests, impact and penetration, smashes and crashes, occupant safety, and more.

Simulate the Response of Materials to Short Periods of Severe Loading

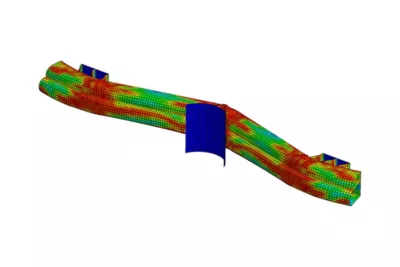

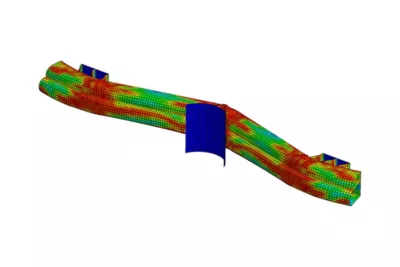

Ansys LS-DYNA is the most used explicit simulation program in the world and is capable of simulating the response of materials to short periods of severe loading. Its many elements, contact formulations, material models and other controls can be used to simulate complex models with control over all the details of the problem. Ansys LS-DYNA applications include:

- Explosion / Penetration

- Drop Test of All Forms

- Bird Strike

- Impacts

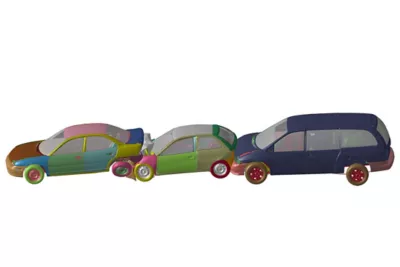

- Crashworthiness / Airbag Simulations

- Product Misuse / Severe Loadings

- Fracture

- Product Failure / Fragmentation

- Splashing / Hydroplaning / Sloshing

- Large Plasticity in Mechanisms

- Incompressible and Compressible Fluids

- Sports Equipment Design

- Stamping / Forming / Drawing / Forging

- Manufacturing Processes Like Machining / Cutting / Drawing

- Biomedical and Medical Devices Simulations

- Vehicle Crash and Occupant Safety

Features

Quick Features & Benefits

LS-DYNA delivers a diverse array of analyses with extremely fast and efficient parallelization.

Still have a question?

Implicit and Explicit Solvers

Frequency Domain Analysis

ICFD for Incompressible Fluid

Electromagnetics Solver

Electromagnetics

Particle Methods

Contact – Linear and Nonlinear

Adaptive Remeshing

Meshless – SPH and ALE

Advanced CAE

Supporting Tools

Total Human Model for Safety (THUMS™)

A Quick Guide to

Licensing Basics

There are three licensing options available with Ansys Mechanical:

Mechanical Pro

Mechanical Premium

Mechanical Enterprise

Full thermal analysis

Modal analysis

Full contact

Non-linear geometry

Material plasticity

Structural optimization

Pre-stressed modal

4 HPC Cores

Full linear dynamics

Element birth and death

Full material non-linearity

Coupled field elements

User Defined Material Model Formulations

Capabilities

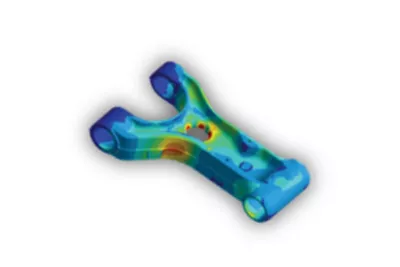

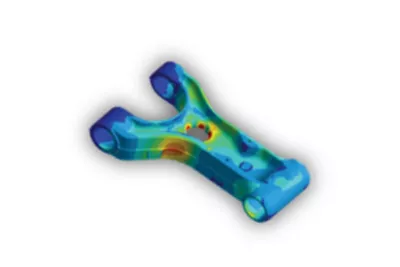

Vast array of capabilities to simulate extreme deformation problems

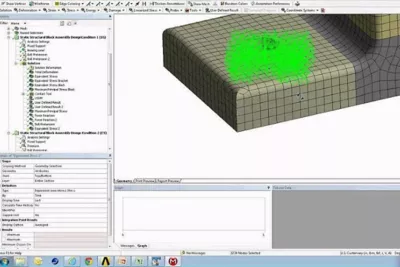

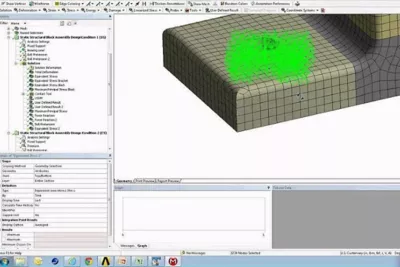

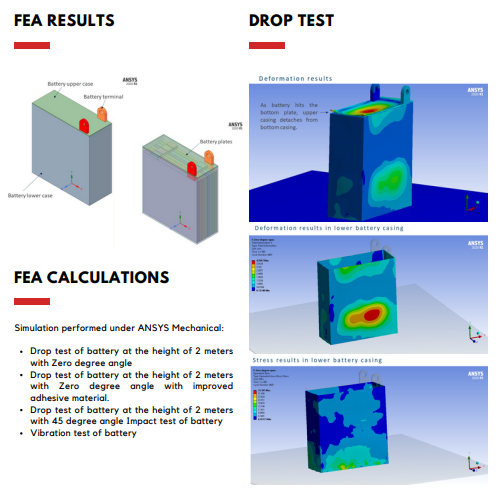

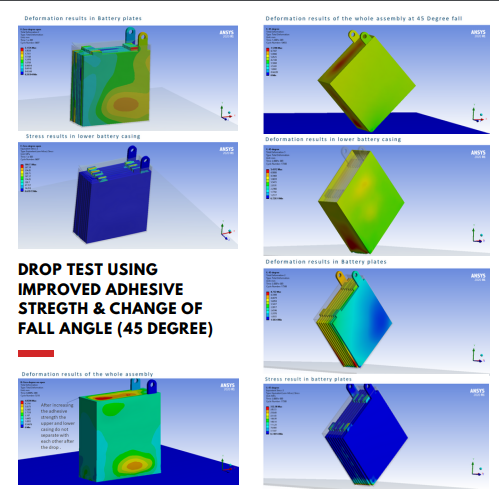

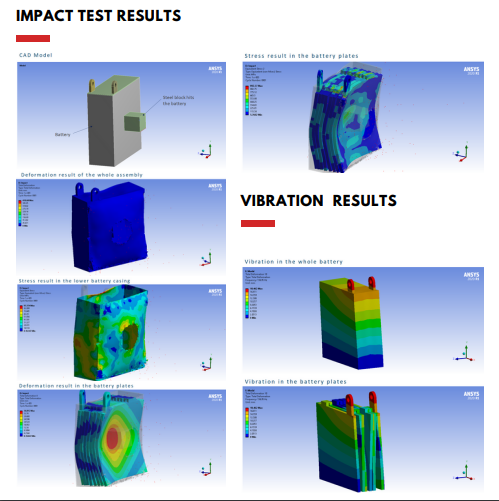

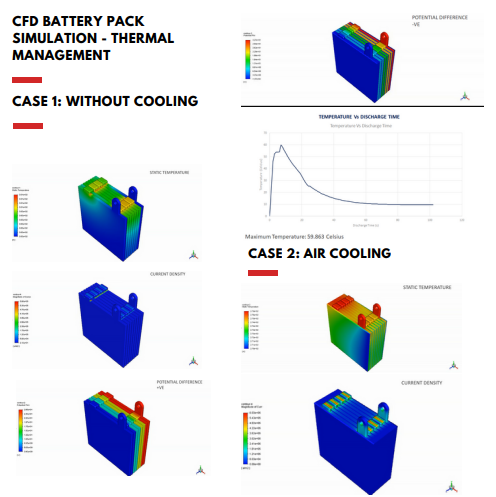

Engineers can tackle simulations involving material failure and look at how the failure progresses through a part or through a system. Models with large amounts of parts or surfaces interacting with each other are also easily handled, and the interactions and load passing between complex behaviors are modeled accurately. Using computers with higher numbers of CPU cores can drastically reduce solution times.

Capabilities

Key Features

LS-DYNA elements, contact formulations, material models and other controls can be used to simulate complex models with control over all the details of the problem.

Implicit and Explicit Solvers

Implicit and Explicit Solvers

Implicit and Explicit Solvers

Implicit and Explicit Solvers Easily switch between Implicit and Explicit solvers for your different runs.

Frequency Domain Analysis

Frequency Domain Analysis

Frequency Domain Analysis

Frequency Domain Analysis Frequency domain analysis allows LS-Dyna users to explore capabilities such as frequency response function, steady state dynamics, random vibration, response spectrum analysis, acoustics BEM and FEM, and fatigue SSD and random vibration. You can use these capabilities for applications such as NVH, acoustic analysis, defense industry, fatigue analysis and earthquake engineering.

ICFD for Incompressible Fluid

ICFD for Incompressible Fluid

ICFD for Incompressible Fluid

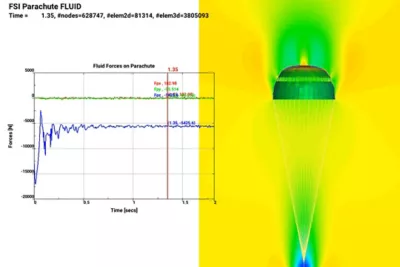

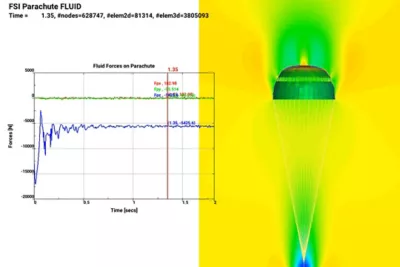

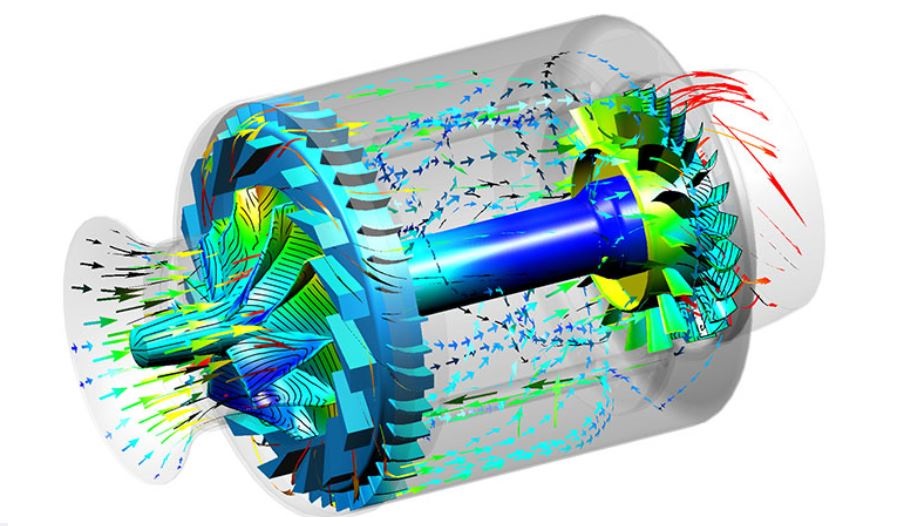

ICFD for Incompressible Fluid ICFD solver is a stand-alone CFD code that includes a steady-state solver, transient solver, turbulence model for RANS/LES, free surface flows and isotropic/anisotropic porous media flow. Coupled to structural, EM solver and thermal solver.

Electromagnetics Solver

Electromagnetics Solver

Electromagnetics Solver

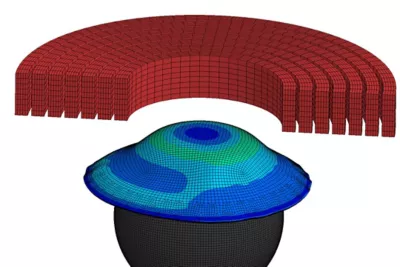

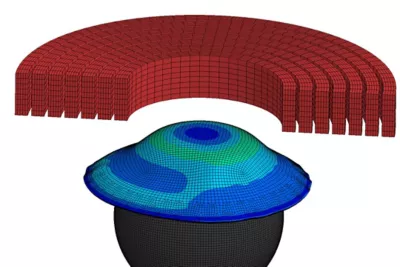

Electromagnetics Solver EM solves the Maxwell equations using FEM & BEM in the Eddy current approximation. This is suitable for cases where the propagation of electromagnetic waves in air (or vacuum) can be considered as instantaneous. The main applications are magnetic metal forming or welding, induced heating, and battery abuse simulation.

Multiphysics Solver

Multiphysics Solver

Multiphysics Solver

Multiphysics Solver Multiphysics Solver include ICFD for Incompressible Fluids, electromagnetic solver, EM for battery abuse, and CESE for compressible fluids.

Particle Methods

Particle Methods

Particle Methods

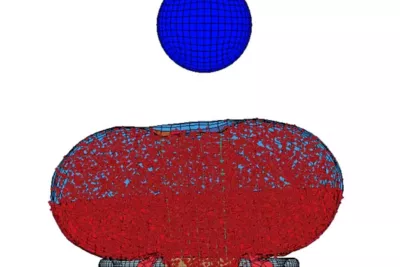

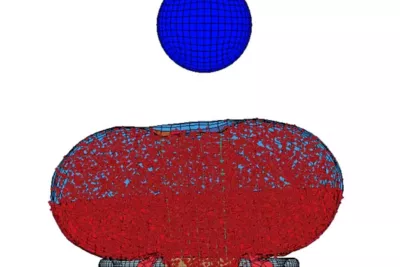

Particle Methods There are several particle methods using LS-Dyna. AIRBAG_PARTICLE is used for for airbag gas particles which models the gas as a set of rigid particles in random motion. PARTICLE_BLAST for high explosive particles which models high explosive gas and air modeled Particle gas. Discrete element method includes applications such as agriculture and food handling, chemical and civil Engineering, mining, mineral processing.

Contact – Linear and Nonlinear

Contact – Linear and Nonlinear

Contact – Linear and Nonlinear

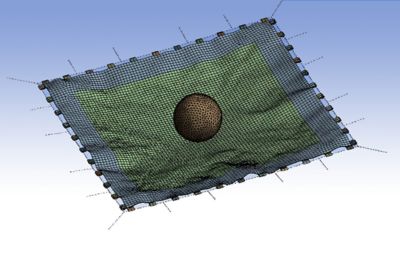

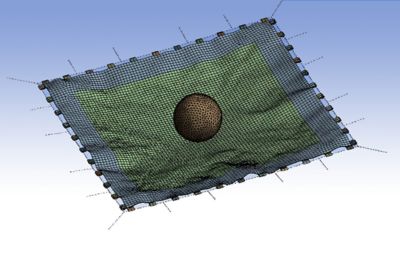

Contact – Linear and Nonlinear In LS-DYNA, a contact is defined by identifying (via parts, part sets, segment sets, and/or node sets) what locations are to be checked for potential penetration of a slave node through a master segment. A search for penetrations, using any of a number of different algorithms, is made every time. In the case of a penalty-based contact, when a penetration is found, a force proportional to the penetration depth is applied to resist, and ultimately eliminate the penetration. Rigid bodies may be included in any penalty-based contact but for that contact force to be realistically distributed, it is recommended that the mesh defining any rigid body be as fine as that of a deformable body.

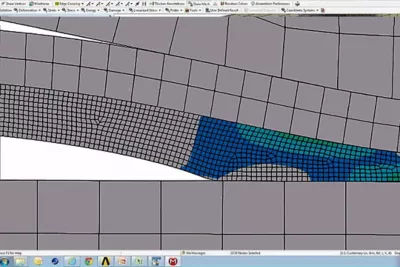

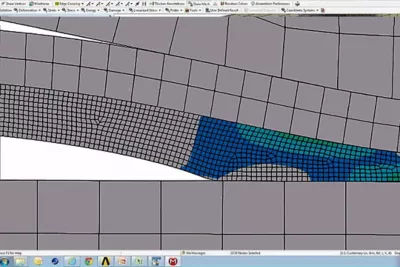

Adaptive Remeshing

Adaptive Remeshing

Adaptive Remeshing

Adaptive Remeshing Several tools are provided for local refinement of the volume mesh in order to better capture mesh sensitive phenomenon’s such as turbulent eddies or boundary layer separation reattachment. During the geometry set up, the user can define surfaces that will be used by the mesher to specify a local mesh size inside the volume. If no internal mesh is used to specify the size, the mesher will use a linear interpolation of the surface sizes that define the volume enclosure.

Meshless SPH

Meshless SPH

Meshless SPH

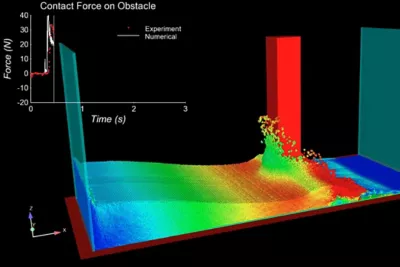

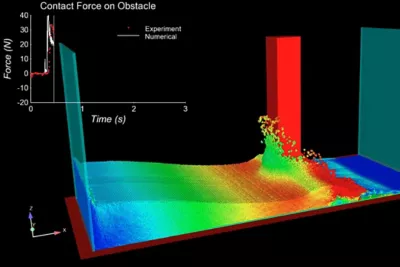

Meshless SPH SPH method in Ansys LS-DYNA® is coupled with the finite and discrete element methods, extending its range of applications to a variety of complex problems involving multiphysics interactions of explosion or fluid-structure interaction.

Meshless ALE

Meshless ALE

Meshless ALE

Meshless ALE Ansys LS-DYNA has two different classes of mesh-free particle solvers: continuum-based smooth particle hydrodynamics (SPH), and discrete particle solvers using the discrete element method (DEM), the particle blast method (PBM) and the corpuscular particle method (CPM). These solvers are used in various applications like hypervelocity impacts; explosions; friction stir welding; water wading; fracture analysis in car windshields, window glass and composite materials; metal friction drilling; metal machining; and high-velocity impact on concrete and metal targets.

Advanced CAE

Advanced CAE

Advanced CAE

Advanced CAE Peridynamics & SPG

The smoothed particle Galerkin (SPG) method is a new Lagrangian particle method for simulating the severe plastic deformation and material rupture taken place in ductile material failure. The Peridynamics method is another compelling method for brittle fracture analysis in isotropic materials as well as certain composites such as CFRP. These two numerical methods share a common feature in modeling the 3D material failure using a bond-based failure mechanism. Since the material erosion technique is no more necessary, the simulation of the material failure processes becomes very effective and stable.

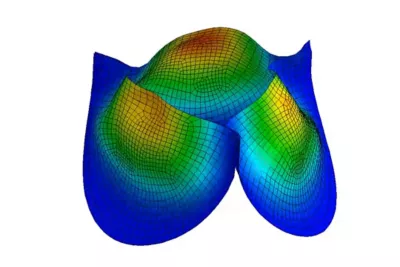

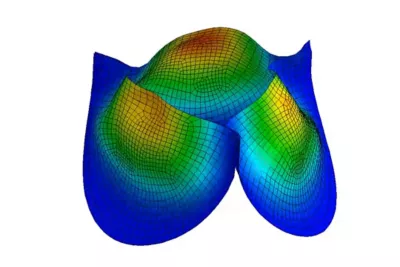

Isogeometric Analysis (IGA)

The isogeometric paradigm employs basis functions from computer-aided design (CAD) for numerical analysis. The actual geometry of the CAD parts is preserved which is in sharp contrast to finite element analysis (FEA) where the geometry is approximated with, potentially higher-order, polynomials. Isogeometric analysis (IGA) has been extensively studied in the past few years in order to (1) reduce the effort of moving between design and analysis representations and (2) obtain higher-order accuracy through the higher-order interelement continuity of the spline basis functions used in CAD. LS-DYNA is the first commercial code to support IGA through the implementation of generalized elements and then keywords supporting non-uniform rational B-splines (NURBS). Many of the standard FEA capabilities, such as contact, spot-weld models, anisotropic constitutive laws, or frequency domain analysis, are readily available in LS-DYNA with new features added steadily.

Supporting Tools

Supporting Tools

Supporting Tools

Supporting Tools LS-OPT

Ansys LS-OPT is a standalone design optimization and probabilistic analysis package with an interface to Ansys LS-DYNA. It is difficult to achieve an optimal design because design objectives are often in conflict. LS-OPT uses a systematic approach involving an inverse process for design optimization: First you specify the criteria and then you compute the best design according to a mathematical framework.

Probabilistic analysis is necessary when a design is subjected to structural and environmental input variations that cause a variation in response that may lead to undesirable behavior or failure. A probabilistic analysis, using multiple simulations, assesses the effect of the input variation on the response variation and determines the probability of failure.

Together, design optimization and probabilistic analysis help you to reach an optimal product design quickly and easily, saving time and money in the process.

Typical applications of LS-OPT include:

- Design optimization

- System identification

- Probabilistic analysis

LS-TaSC

LS-TaSC™ is a Topology and Shape Computation tool. Developed for engineering analysts who need to optimize structures, LS-TaSC works with both the implicit and explicit solvers of LS-DYNA. LS-TaSC handles topology optimization of large nonlinear problems, involving dynamic loads and contact conditions.

Supporting Tools/LST Models

Supporting Tools/LST Models

Supporting Tools/LST Models

Supporting Tools/LST Models Dummies

Anthropomorphic Test Devices (ATDs), as known as “crash test dummies”, are life-size mannequins equipped with sensors that measure forces, moments, displacements, and accelerations. These measurements can then be interpreted to predict the extent of injuries that a human would experience during an impact. Ideally, ATDs should behave like real human beings while being durable enough to produce consistent results across multiple impacts. There are a wide variety of ATDs available to represent different human sizes and shapes.

Barriers

LSTC offers several Offset Deformable Barrier (ODB) and Movable Deformable Barrier (MDB) models. LSTC ODB and MDB models are developed to correlate to several tests provided by our customers. These tests are proprietary data and are not currently available to the public.

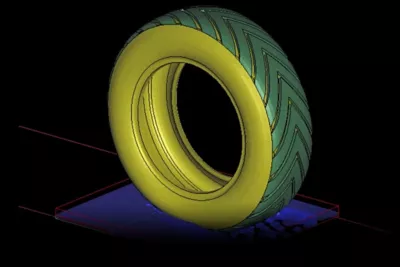

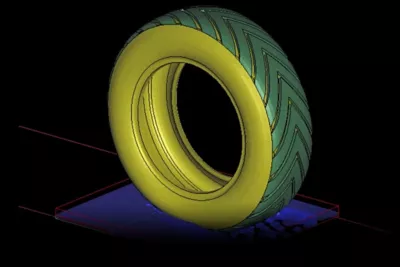

Tires

LST jointly developed tire models with FCA. These models can be downloaded through the LST, Models download section. The models are based on a series of material, verification, and component level tests. The finite element mesh is based on 2D CAD data of the tire section. All major components of the tire use 8-noded hexahedron elements. The elastomers are modeled using *MAT_SIMPLIFIED_RUBBER and the plies are modeled using *MAT_ORTHOTROPIC_ELASTIC.

Visioneering

Recent Events &

Webinars

Discover how engineering simulation is expanding across the entire product lifecycle.

Ansys Multiphysics

Conference

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Future Tech Expo 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Ansys Multiphysics

Conference

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Visioneering

Blogs & Trends

Discover how engineering simulation is expanding across the entire product lifecycle. engineering / product design analysis by modeling & simulation.

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Innovate

Breaking News & White Paper

Discover how engineering simulation is expanding across the entire product lifecycle.

Smart Strategies for Large Structural Simulations

One way to gauge the progress of engineering simulation software is through the lens of size. Engineers today routinely run structural simulations with a few million degrees of freedom, and the largest commercial structural simulations have topped even 100 million degrees of freedom.

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

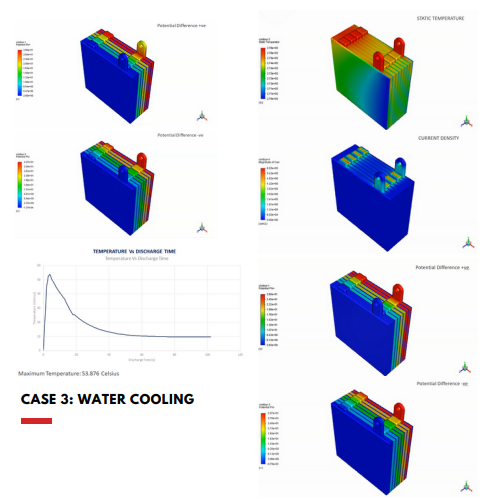

Studies

case

Explore Case Studies

Qantur Technologies is a pioneer engineering simulations company based in Gurgaon –India. We provides expert Computer Aided Engineering – CAE consulting services for engineering / product design analysis by modeling & simulation.

Download Case Study

Transform Ideas into Reality—Explore Our Simulation Solutions Today!

Partner with Us to Revolutionize Engineering Excellence!

Testimonials

Customer Testimonials

Bengal Industries Pvt. Ltd

The ANSYS Mechanical training conducted by Qantur Technologies was highly informative and helped our engineers resolve critical challenges in contact modeling, meshing, and fatigue analysis. The sessions were well-coordinated, delivered on schedule, and supported with patient guidance by the trainer and account manager. We truly value Qantur’s expertise, professionalism, and post-sales support.

Bengal Industries Pvt. Ltd

Bliss Anand Pvt. Ltd.

During our evaluation of CFD solutions, Qantur Technologies stood out for their technical expertise, reliability, and customer-focused approach. Their consulting projects achieved 98% accuracy compared to experimental values, instilling strong confidence in their capabilities. Based on this experience, we selected them as our preferred partner for ANSYS software, consulting, training, and support. We highly recommend their services to organizations with simulation requirements.

Bliss Anand Pvt. Ltd.

CUET, Department of Mechanical Engineering

We experienced significant value from Qantur Technologies’ expertise in ANSYS solutions, particularly in FEA and CFD consulting. Their skilled engineers provided insightful training on geometry, meshing, and modeling, which enhanced our students’ and faculty’s analytical skills. With exceptional support and patience from their trainers, we are pleased to recommend Qantur Technologies for ANSYS implementation, training, and advanced simulation services.

CUET, Department of Mechanical Engineering

Entecnia Consulting Pvt. Ltd.

Our collaboration with Qantur Technologies for ANSYS implementation and consulting has been outstanding. Their commitment, technical expertise, and timely support in FEA and CFD have added significant value to our engineering and R&D teams. The exclusive 15-day training session further enhanced our team’s analytical skills, and we truly appreciate their professionalism and ownership in managing the entire process seamlessly. We highly recommend Qantur Technologies for advanced CAE solutions.

Entecnia Consulting Pvt. Ltd.

Flovel Energy Pvt. Ltd.

Our experience with Qantur Technologies in implementing ANSYS HPC and CFD solutions has been remarkable. Their skilled engineers conducted in-depth training for our R&D team, equipping us with advanced methods to simulate hydro turbines and enhance component performance. Their reliable support, technical expertise, and resource assistance make them a trusted partner for ANSYS software, consulting, and training. We highly recommend Qantur Technologies for any ANSYS-related services.

Flovel Energy Pvt. Ltd.

Flovel Energy Pvt. Ltd.

We truly value the ANSYS SpaceClaim training conducted by Qantur Technologies at our R&D center. The course was tailored to our requirements, highly informative, and supported by hands-on workshops that enhanced our team’s modeling skills. Their application engineer was proactive, helpful, and ensured customization aligned with our needs. We look forward to engaging Qantur Technologies again for future application-based trainings.

Flovel Energy Pvt. Ltd.

IoTechWorld Avigation Pvt. Ltd.

At IoTechWorld, we develop advanced drones for agriculture, survey, and surveillance, and ANSYS Mechanical & CFD have been instrumental in optimizing our designs. Qantur Technologies supported us with the right resources, training, and technical expertise to address complex FEA & CFD challenges. Their team’s commitment and knowledge have empowered us to innovate faster and more effectively. We highly recommend Qantur Technologies for ANSYS implementation, consulting, and support.

IoTechWorld Avigation Pvt. Ltd.

Karman Drones Pvt. Ltd.

Our collaboration with Qantur Technologies for At Karman Drones, innovation drives our mission in AI-powered autonomous drones. Qantur Technologies has been a key partner in implementing ANSYS software, providing outstanding FEA & CFD expertise, consulting, and hands-on training. Their engineers have empowered our team with advanced simulation knowledge, improving design validation, performance optimization, and overall efficiency. We highly recommend Qantur Technologies for their exceptional support and technical proficiency.

Karman Drones Pvt. Ltd.

Mittal Electronics

At Mittal Electronics, innovation and R&D are at the heart of our product development. Partnering with Qantur Technologies for ANSYS FEA & CFD has been transformative—helping us accelerate design validation, optimize performance, and tackle complex engineering challenges with confidence. Their expert training, consulting, and quick response have greatly strengthened our engineering capabilities. We look forward to continued collaboration with Qantur Technologies.

Mittal Electronics

MV Electrosystems Pvt. Ltd.

At MV Electrosystems, innovation in rail transportation demands precision and reliability. Partnering with Qantur Technologies for ANSYS ICEPAK & Mechanical has significantly enhanced our ability to optimize product design, improve efficiency, and accelerate development. Their expert training, technical guidance, and hands-on support in FEA & CFD not only strengthened our engineering skills but also deepened our understanding of core physics. We truly value this collaboration and highly recommend Qantur Technologies for simulation-driven innovation.

MV Electrosystems Pvt. Ltd.

Nicotra India Pvt. Ltd.

At Nicotra India, precision in fan design is critical. Qantur Technologies has been a valuable partner, providing quick and responsive CFD support—both onsite and online—that helped us validate designs and solve complex meshing and model setup challenges. Their extensive training sessions empowered our R&D team with practical simulation expertise, strengthening our analytical and design capabilities. We are pleased with their services and highly recommend them for ANSYS implementation and technical support.

Nicotra India Pvt. Ltd.

NTF (India) Pvt. Ltd.

At NTF India, we rely on advanced engineering solutions to deliver world-class automotive components. Qantur Technologies has been a trusted partner, supporting us with ANSYS implementation and in-depth FEA analysis for our key projects. Their professionalism, technical expertise, and ability to deliver under challenging conditions have consistently exceeded our expectations. We highly value their commitment and look forward to continued collaboration on future product development initiatives.

NTF (India) Pvt. Ltd.

Onassis Auto Limited

At Onassis Auto, precision and reliability are at the core of our automotive components. With Qantur Technologies’ guidance in Ansys Mechanical, we have successfully enhanced our engineering capabilities, optimized transmission components, and improved efficiency. Their hands-on training, prompt support, and expertise in FEA have greatly empowered our R&D team. We are pleased to recommend Qantur Technologies for their outstanding technical services and commitment.

Onassis Auto Limited

P2P Analysis & Solutions

At P2P Analysis & Solutions, innovation is our core, and Qantur Technologies has been an invaluable partner in this journey. Their technical excellence in Ansys Mechanical and LS-DYNA, coupled with meticulous training and proactive support, has empowered our team to solve complex challenges with confidence. Their professionalism, collaborative approach, and customer-centric commitment make them a trusted long-term partner. We strongly recommend Qantur Technologies for any Ansys-related solutions and services.

P2P Analysis & Solutions

S&O Marintime

S&O Marintime