Products

Ansys Motion

Multibody Dynamics Simulation Software

Ansys Motion, now in the Ansys Mechanical interface, is a third-generation engineering solution based on an advanced multibody dynamics solver. It enables fast and accurate analysis of rigid and flexible bodies, and gives accurate evaluation of physical events through the analysis of the mechanical system as a whole.

Robust Multibody Dynamic System Design with Ansys Motion

Ansys Motion is a completely integrated simulation environment for both component and system modeling. It provides fast and accurate analysis for both rigid and flexible bodies, simultaneously, all from a single solver. System motion performance, stress-safety analysis, heat transfer, vibration and fatigue are integral. Ansys Motion is the most robust and advanced simulation solution for multibody dynamic system design.

- Car

- Drivetrain

- Links

- EasyFlex

Features

Quick Specs

Perform simulations in Ansys Motion in the same interface as your regular structural analysis. One model can be re-used for many purposes, resulting in huge time savings. Specs include the Ansys Motion Links modeler for tracked vehicles, FE Dynamics tools, and more.

Still have a question?

Multibody Dynamics Analysis

Drivetrain Toolkit

FE Dynamics

MATLAB Interface

Car Toolkit

EasyFlex Toolkit

API Development

SMP and MPP

Links Toolkit

Linear

Modal Flex

Parametric Gear Creation

Libraries of Bearings

Capabilities

Ansys Motion Is A New Paradigm in Flexible Multibody Dynamics (MBD)

Ansys Motion is a next-generation engineering solution based on flexible multibody dynamics. It enables fast and accurate analysis of rigid and flexible bodies within a single solver system. Motion can reduce time-to-market by performing system motion performance, stress safety analysis, vibration analysis and fatigue analysis during the design process across many industrial applications. Motion’s integrated GUI provides a robust modeling environment for component and systems that can be analyzed independently or simultaneously, opening new doors during design and analysis.

Explore more Ansys Motion capabilities below.

Capabilities

Key Features

Solver

Solver

Solver

Solver The Motion solver can accelerate the simulation speed for large degree of freedom systems.

Simulate faster using shared memory parallel processing (SMP) and massive parallel processing (MPP) environments.

Pre-post Processor

Pre-post Processor

Pre-post Processor

Pre-post Processor Ansys Motion pre-processor provides an optimized modeling environment for components and systems.

Components can be modeled as a single entity consisting of a part file and a mesh file. Part files and mesh files are treated and managed independently, allowing for data reuse in other models.

Post-processor provides fast animation of a system consisting of complicated geometries.

MBD Pro

MBD Pro

MBD Pro

MBD Pro MBD Pro is included in the Ansys Motion base package and is a module to analyze rigid body systems.

The governing equations of motion are formulated based on a parametric generalized coordinate system. The rigid bodies are connected by joints, primitive constraints, bushings, contacts and user-defined function expressions. Smooth surface-to-surface contact is supported. The surface can be represented by piecewise triangular patches or a NURBS surface.

FE Dynamics

FE Dynamics

FE Dynamics

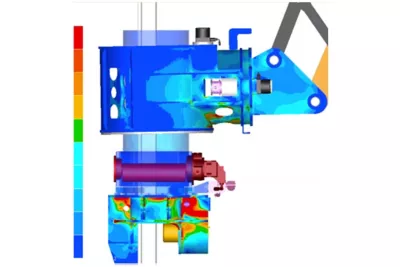

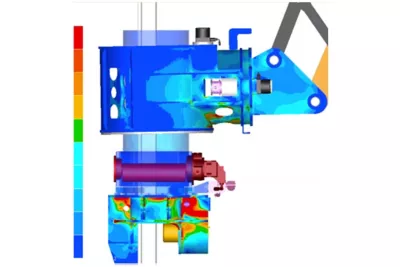

FE Dynamics Perform dynamic analysis of a mixed system of rigid and flexible bodies.

The solver was originally designed to contain the two different disciplines of MBD and finite element (FE) analysis. Therefore, there are many unique connecting elements of rigid and flexible bodies. Since the numerically stable implicit integration method is used, the solution is free from numerical noise and very smooth and reliable.

Modal Flex

Modal Flex

Modal Flex

Modal Flex When a flexible body has no contact or mildly changing force elements, the modal flexible body is preferred due to its efficiency.

Mode shapes are extracted from a finite element program such as Ansys Mechanical and deformation is expressed by the linear combination of the mode shapes. Since it solves reduced modal coordinates, the computation time is short. Modal flexible body and full nodal flexible body can be switched easily and can be solved with other rigid and nodal flexible bodies.

Linear

Linear

Linear

Linear Linear analysis is used to solve eigenvalues and eigenvectors of FE bodies, EasyFlex bodies or systems.

Natural frequencies and modes can be simulated. For the body eigenvalue analysis, the static correction mode will deliver a more accurate solution of a modal flexible body.

Fatigue

Fatigue

Fatigue

Fatigue Conventional fatigue analysis has required two independent analyses of load history and stresses.

These two processes are combined as one in the Ansys Motion fatigue analysis system. The Ansys Motion solver generates the load history and stress history at the same time. The fatigue life can be directly visualized in Ansys Motion post-processor.

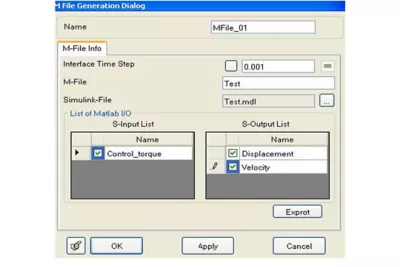

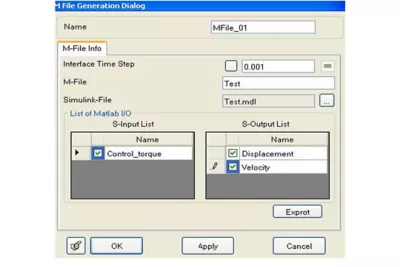

MATLAB Interface

MATLAB Interface

MATLAB Interface

MATLAB Interface Included in Ansys Motion base package, MATLAB/Simulink interface allows co-simulation of MATLAB control model and Ansys Motion mechanical models.

System input/output in the Ansys Motion model and Simulink file in MATLAB must be defined.

FMI

FMI

FMI

FMI A functional mockup interface (FMI) capability facilitates co-simulation of an Ansys Motion mechanical model with other simulation tools that support FMI.

System input/output in the Ansys Motion model must be defined. Ansys Motion’s FMI is only available as a slave simulator.

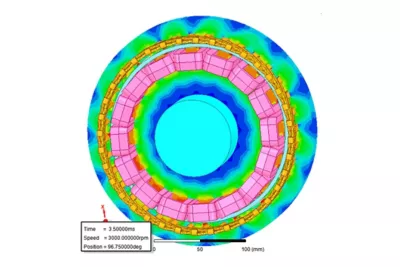

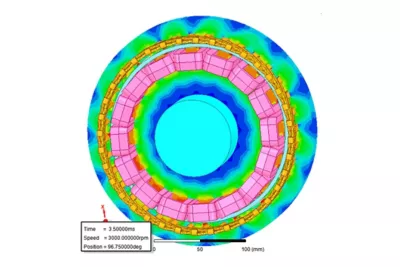

Drivetrain Toolkit

Drivetrain Toolkit

Drivetrain Toolkit

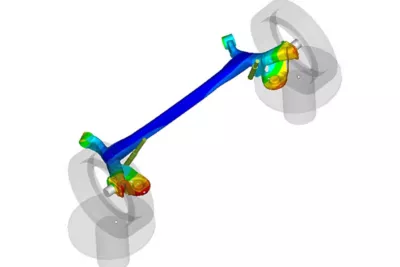

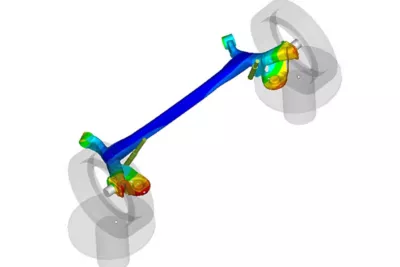

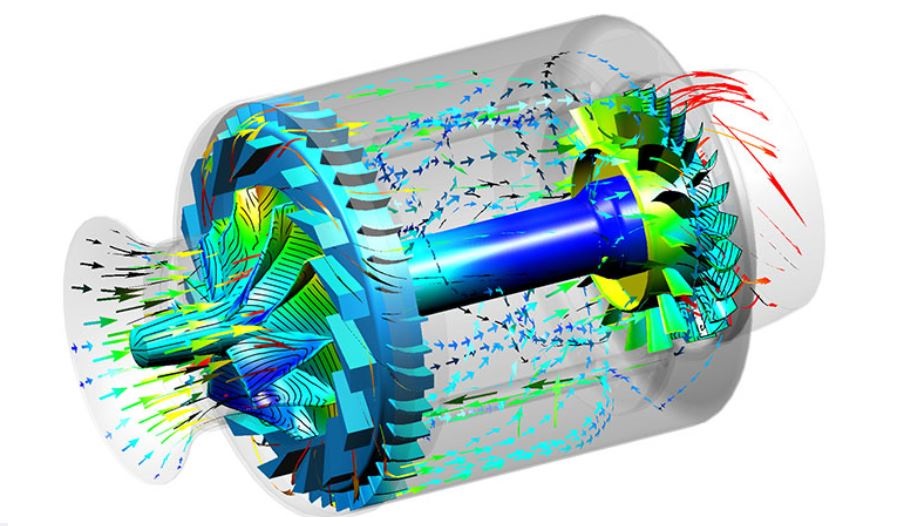

Drivetrain Toolkit Ansys Motion Drivetrain toolkit can analyze the noise, vibration and harshness (NVH) characteristics of drivetrain systems under variable driving conditions.

It can conduct analyses from the initial design concept through to detailed production models. Waterfall color maps and order tracking data can be produced in the same manner as in a real-world test environment to allow easy comparison of simulation and reality.

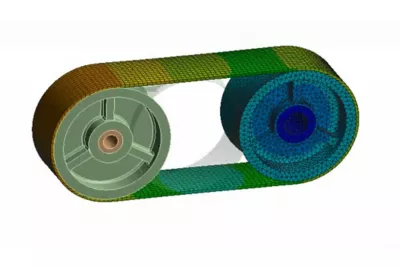

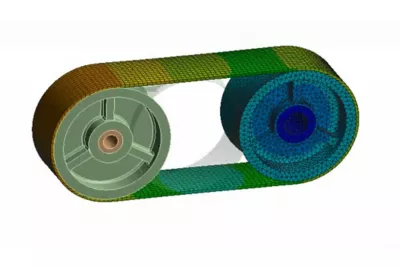

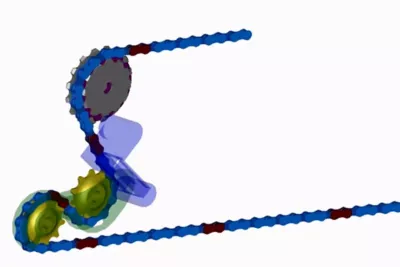

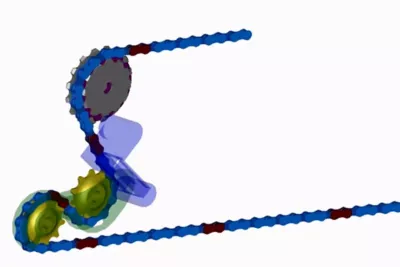

Links Toolkit for Chains and Belts

Links Toolkit for Chains and Belts

Links Toolkit for Chains and Belts

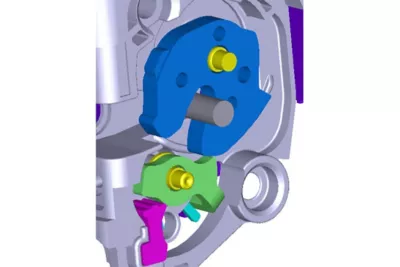

Links Toolkit for Chains and Belts An Ansys Motion Links toolkit analysis consists of path bodies (wound bodies) and segment bodies (winding bodies).

Once the path and segment bodies are defined, a chain assembly is automatically created. Path and segment bodies can be a subsystem, part or mesh files. This allows a user to build various types of irregular chains. One window controls all the contact parameters among the segment and path bodies. Connections between two segments can be any kind of force, joint or contact entity.

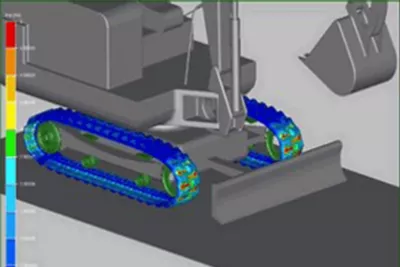

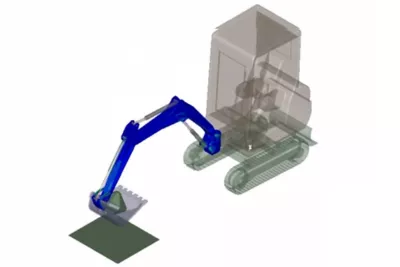

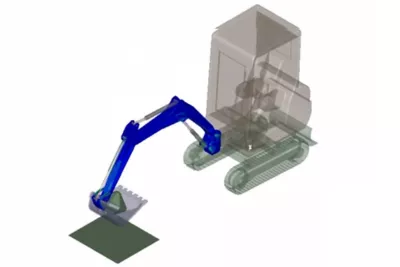

Links Toolkit for Tracks

Links Toolkit for Tracks

Links Toolkit for Tracks

Links Toolkit for Tracks Predefined geometries for segment and path bodies are provided so that a parametric study is possible.

Track assembly is further simplified to eliminate the picking step of path bodies. The path bodies are automatically searched and used to automatically assemble the track segments. Contact surfaces are automatically defined for the predefined geometries so that contact surfaces do not need to be defined. The predefined geometries have complicated modeling details to represent the real shapes.

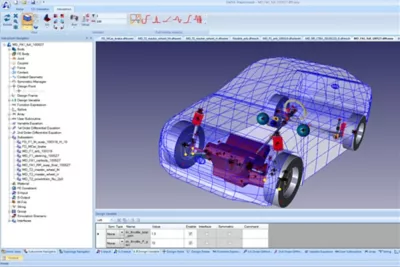

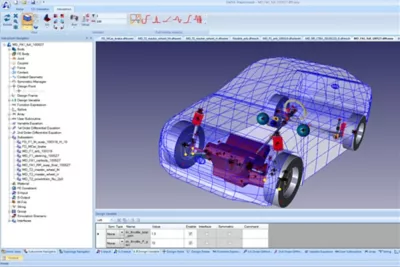

Car Toolkit

Car Toolkit

Car Toolkit

Car Toolkit Dedicated template and subsystem modeling tools can be used to build chassis, suspension, steering and wheels for predefined analysis scenarios.

Symmetric modeling capabilities and template-based workflows allow users to easily analyze kinematics and compliance (K&C) and ride and handling (R&H) scenarios.

EasyFlex Toolkit

EasyFlex Toolkit

EasyFlex Toolkit

EasyFlex Toolkit Unlike conventional finite element analysis, the Ansys Motion EasyFlex toolkit does not require meshing prior to structural analysis.

Since the meshing of complex 3D CAD is not needed, it makes flexibility modeling available to all users, even those unfamiliar with meshing technologies. By using the Ansys Motion EasyFlex toolkit, the strain and stress of machine parts with various shapes can be calculated within minutes.

Translators

Translators

Translators

Translators A user-friendly interface with a wide range of tools, wizards, and visualizations to assist engineers in the design and analysis process.

Other CAD data files must be translated through the corresponding CAD translator.

Visioneering

Recent Events &

Webinars

Discover how engineering simulation is expanding across the entire product lifecycle.

Ansys Multiphysics

Conference

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Future Tech Expo 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Ansys Multiphysics

Conference

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Visioneering

Blogs & Trends

Discover how engineering simulation is expanding across the entire product lifecycle. engineering / product design analysis by modeling & simulation.

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Innovate

Breaking News & White Paper

Discover how engineering simulation is expanding across the entire product lifecycle.

Smart Strategies for Large Structural Simulations

One way to gauge the progress of engineering simulation software is through the lens of size. Engineers today routinely run structural simulations with a few million degrees of freedom, and the largest commercial structural simulations have topped even 100 million degrees of freedom.

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

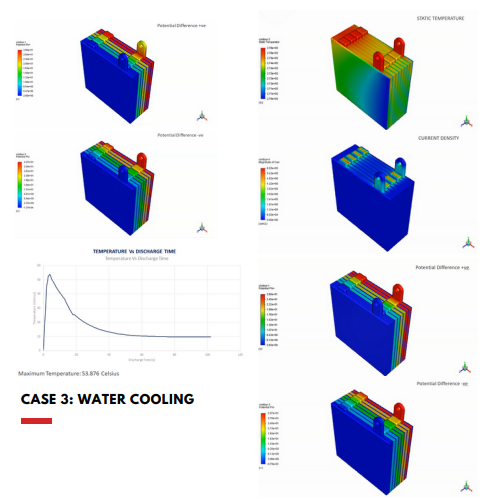

studies

Case

Explore Case Studies

Qantur Technologies is a pioneer engineering simulations company based in Gurgaon –India. We provides expert Computer Aided Engineering – CAE consulting services for engineering / product design analysis by modeling & simulation.

Download Case Study

Transform Ideas into Reality—Explore Our Simulation Solutions Today!

Partner with Us to Revolutionize Engineering Excellence!

Testimonials

Customer Testimonials

Bengal Industries Pvt. Ltd

The ANSYS Mechanical training conducted by Qantur Technologies was highly informative and helped our engineers resolve critical challenges in contact modeling, meshing, and fatigue analysis. The sessions were well-coordinated, delivered on schedule, and supported with patient guidance by the trainer and account manager. We truly value Qantur’s expertise, professionalism, and post-sales support.

Bengal Industries Pvt. Ltd

Bliss Anand Pvt. Ltd.

During our evaluation of CFD solutions, Qantur Technologies stood out for their technical expertise, reliability, and customer-focused approach. Their consulting projects achieved 98% accuracy compared to experimental values, instilling strong confidence in their capabilities. Based on this experience, we selected them as our preferred partner for ANSYS software, consulting, training, and support. We highly recommend their services to organizations with simulation requirements.

Bliss Anand Pvt. Ltd.

CUET, Department of Mechanical Engineering

We experienced significant value from Qantur Technologies’ expertise in ANSYS solutions, particularly in FEA and CFD consulting. Their skilled engineers provided insightful training on geometry, meshing, and modeling, which enhanced our students’ and faculty’s analytical skills. With exceptional support and patience from their trainers, we are pleased to recommend Qantur Technologies for ANSYS implementation, training, and advanced simulation services.

CUET, Department of Mechanical Engineering

Entecnia Consulting Pvt. Ltd.

Our collaboration with Qantur Technologies for ANSYS implementation and consulting has been outstanding. Their commitment, technical expertise, and timely support in FEA and CFD have added significant value to our engineering and R&D teams. The exclusive 15-day training session further enhanced our team’s analytical skills, and we truly appreciate their professionalism and ownership in managing the entire process seamlessly. We highly recommend Qantur Technologies for advanced CAE solutions.

Entecnia Consulting Pvt. Ltd.

Flovel Energy Pvt. Ltd.

Our experience with Qantur Technologies in implementing ANSYS HPC and CFD solutions has been remarkable. Their skilled engineers conducted in-depth training for our R&D team, equipping us with advanced methods to simulate hydro turbines and enhance component performance. Their reliable support, technical expertise, and resource assistance make them a trusted partner for ANSYS software, consulting, and training. We highly recommend Qantur Technologies for any ANSYS-related services.

Flovel Energy Pvt. Ltd.

Flovel Energy Pvt. Ltd.

We truly value the ANSYS SpaceClaim training conducted by Qantur Technologies at our R&D center. The course was tailored to our requirements, highly informative, and supported by hands-on workshops that enhanced our team’s modeling skills. Their application engineer was proactive, helpful, and ensured customization aligned with our needs. We look forward to engaging Qantur Technologies again for future application-based trainings.

Flovel Energy Pvt. Ltd.

IoTechWorld Avigation Pvt. Ltd.

At IoTechWorld, we develop advanced drones for agriculture, survey, and surveillance, and ANSYS Mechanical & CFD have been instrumental in optimizing our designs. Qantur Technologies supported us with the right resources, training, and technical expertise to address complex FEA & CFD challenges. Their team’s commitment and knowledge have empowered us to innovate faster and more effectively. We highly recommend Qantur Technologies for ANSYS implementation, consulting, and support.

IoTechWorld Avigation Pvt. Ltd.

Karman Drones Pvt. Ltd.

Our collaboration with Qantur Technologies for At Karman Drones, innovation drives our mission in AI-powered autonomous drones. Qantur Technologies has been a key partner in implementing ANSYS software, providing outstanding FEA & CFD expertise, consulting, and hands-on training. Their engineers have empowered our team with advanced simulation knowledge, improving design validation, performance optimization, and overall efficiency. We highly recommend Qantur Technologies for their exceptional support and technical proficiency.

Karman Drones Pvt. Ltd.

Mittal Electronics

At Mittal Electronics, innovation and R&D are at the heart of our product development. Partnering with Qantur Technologies for ANSYS FEA & CFD has been transformative—helping us accelerate design validation, optimize performance, and tackle complex engineering challenges with confidence. Their expert training, consulting, and quick response have greatly strengthened our engineering capabilities. We look forward to continued collaboration with Qantur Technologies.

Mittal Electronics

MV Electrosystems Pvt. Ltd.

At MV Electrosystems, innovation in rail transportation demands precision and reliability. Partnering with Qantur Technologies for ANSYS ICEPAK & Mechanical has significantly enhanced our ability to optimize product design, improve efficiency, and accelerate development. Their expert training, technical guidance, and hands-on support in FEA & CFD not only strengthened our engineering skills but also deepened our understanding of core physics. We truly value this collaboration and highly recommend Qantur Technologies for simulation-driven innovation.

MV Electrosystems Pvt. Ltd.

Nicotra India Pvt. Ltd.

At Nicotra India, precision in fan design is critical. Qantur Technologies has been a valuable partner, providing quick and responsive CFD support—both onsite and online—that helped us validate designs and solve complex meshing and model setup challenges. Their extensive training sessions empowered our R&D team with practical simulation expertise, strengthening our analytical and design capabilities. We are pleased with their services and highly recommend them for ANSYS implementation and technical support.

Nicotra India Pvt. Ltd.

NTF (India) Pvt. Ltd.

At NTF India, we rely on advanced engineering solutions to deliver world-class automotive components. Qantur Technologies has been a trusted partner, supporting us with ANSYS implementation and in-depth FEA analysis for our key projects. Their professionalism, technical expertise, and ability to deliver under challenging conditions have consistently exceeded our expectations. We highly value their commitment and look forward to continued collaboration on future product development initiatives.

NTF (India) Pvt. Ltd.

Onassis Auto Limited

At Onassis Auto, precision and reliability are at the core of our automotive components. With Qantur Technologies’ guidance in Ansys Mechanical, we have successfully enhanced our engineering capabilities, optimized transmission components, and improved efficiency. Their hands-on training, prompt support, and expertise in FEA have greatly empowered our R&D team. We are pleased to recommend Qantur Technologies for their outstanding technical services and commitment.

Onassis Auto Limited

P2P Analysis & Solutions

At P2P Analysis & Solutions, innovation is our core, and Qantur Technologies has been an invaluable partner in this journey. Their technical excellence in Ansys Mechanical and LS-DYNA, coupled with meticulous training and proactive support, has empowered our team to solve complex challenges with confidence. Their professionalism, collaborative approach, and customer-centric commitment make them a trusted long-term partner. We strongly recommend Qantur Technologies for any Ansys-related solutions and services.

P2P Analysis & Solutions

S&O Marintime

S&O Marintime