Products

Overview

ADVANCED SAFETY & SECURITY High Level Features

Ansys safety & cybersecurity threat analysis software facilitates model-based safety analysis, safety concept creation, safety management and cybersecurity assessment for safety-critical electrical and electronic (E/E) and software (SW) controlled systems.

Using this software, engineers can deliver safe and secure products, reduce time to market, maximize profit margins and comply with standards like ISO 26262, IEC 61508, ARP 4754A/ARP 4761, ISO 21448 and ISO 21434.

Products

Safety Analysis Products

Qantur Technologies is a pioneer engineering simulations company based in Gurgaon –India. We provides expert Computer Aided Engineering – CAE consulting services for engineering / product design analysis by modeling & simulation.

Ansys implements key safety analysis methods in one integrated tool. It supports the efficient and consistent execution of the analysis activities that are required by safety standards.

- Key safety analysis methods, all in one integrated tool

- Meets standards like ISO 26262, IEC 61508, ARP4761 and MIL-STD 882E

- Safety analysis based on system design with all-time consistency

- Quality analysis according to SAE J1739, VDA-AIAG FMEA Handbook, etc.

- Complete end-to-end traceability

- Integrated with partner and 3rd party tools for requirements management and system design

By acting as a central hub for gathering data, managing resources, planning and automating many process steps, Ansys enables a comprehensive view on safety.

- Tool Guided Safety Planning

- Assisted Reuse of Results

- Easy One-Click Safety Case

- Task Based Safety Plan Execution and Reviews

- KPI Monitoring and Reporting

Capabilities

Key Features

Easily handle the complexity of varied design environments with a range of analytical tools that enable you to meet performance goals and ensure long-term reliability.

Streamline and automate functional safety analysis

Streamline and automate functional safety analysis

Streamline and automate functional safety analysis

Streamline and automate functional safety analysis Functional safety standards, such as ISO 26262, are critical for ensuring that safety-critical electronic systems are reliably delivering consistent performance over time, without system failures. With Ansys medini analyze, the system functions are analyzed for potential hazards and a risk classification is completed. Subsequently, safety requirements are derived to implement appropriate countermeasures to mitigate the risks.

Systematic identification and consideration of SOTIF risks

Systematic identification and consideration of SOTIF risks

Systematic identification and consideration of SOTIF risks

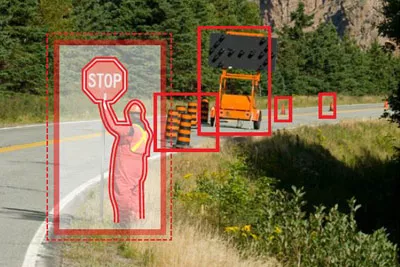

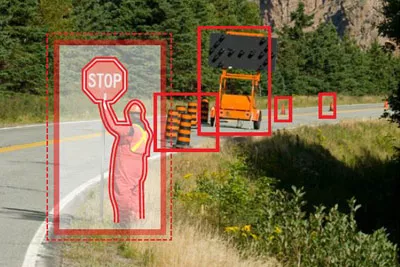

Systematic identification and consideration of SOTIF risks ISO 21448 “Road Vehicles – Safety of the Intended Functionality” (SOTIF) is a new standard that examines whether a system is sufficiently safe even in the absence of failures when hazards are caused by e.g. performance limitations of sensors or perception algorithms, unexpected changes in the road environment, etc. It enables engineering teams to avoid situations where vehicles are working as designed, but are falling short under real-world scenarios.

Ansys medini analyze enables the systematic identification of SOTIF risks in the hazard and risk analysis stage, as well as the consideration of design limitations and triggering conditions. Once these are identified, countermeasures can be planned to meet safety requirements. These measures and requirements are traced in Ansys medini analyze to the functional or architectural updates that are completed during the implementation of the system. Ansys medini analyze provides analysis methods like cause-effect-nets, System Weakness Analysis tables, and event trees, which make systematic analysis, understanding and elimination of SOTIF hazards possible.

This enables diverse teams — working to meet functional safety and SOTIF standards across system, electronics, embedded software, and other areas — to collaborate easily and more seamlessly.

Systematic cybersecurity threat analysis and risk assessment

Systematic cybersecurity threat analysis and risk assessment

Systematic cybersecurity threat analysis and risk assessment

Systematic cybersecurity threat analysis and risk assessment The key to ensuring the cybersecurity of systems is to systematically perform threat analyses and risk assessment across the entire electronics architecture. By identifying every possible means of cyberattack — and estimating both their impact and their feasibility — Ansys medini analyze protects against damaging threats.

This model-based, integrated tool provides end-to-end traceability, along with powerful collaboration, task management and reporting capabilities.

Assess the functional safety of semiconductors

Assess the functional safety of semiconductors

Assess the functional safety of semiconductors

Assess the functional safety of semiconductors Safety analysts must look beneath the surface of semiconductors to assess all failure modes and determine how a flaw in a single chip could manifest itself in a product’s overall performance.

Digital Safety Management

Digital Safety Management

Digital Safety Management

Digital Safety Management Safety and engineering teams can get a comprehensive view of the entire safety planning process – beyond the individual project level. By replacing traditional point-tools, Ansys Digital Safety Manager defines safety plans, controls their execution, centralizes data and monitors outcomes. It helps to construct the safety case by providing efficient automations.

Ansys Digital Safety Manager recognizes and reflects the way safety teams work every day, not only internally but with their suppliers, assessors, and reviewers. It improves efficiency with traceability and standardization to enable systematic and consistent reuse of safety plans and work products.

Visioneering

Recent Events & Webinars

Discover how engineering simulation is expanding across the entire product lifecycles.

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Visioneering

Blogs & Trends

Discover how engineering simulation is expanding across the entire product lifecycle. engineering / product design analysis by modeling & simulation.

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Innovate

Breaking News & White Paper

Discover how engineering simulation is expanding across the entire product lifecycle.

Smart Strategies for Large Structural Simulations

One way to gauge the progress of engineering simulation software is through the lens of size. Engineers today routinely run structural simulations with a few million degrees of freedom, and the largest commercial structural simulations have topped even 100 million degrees of freedom.

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

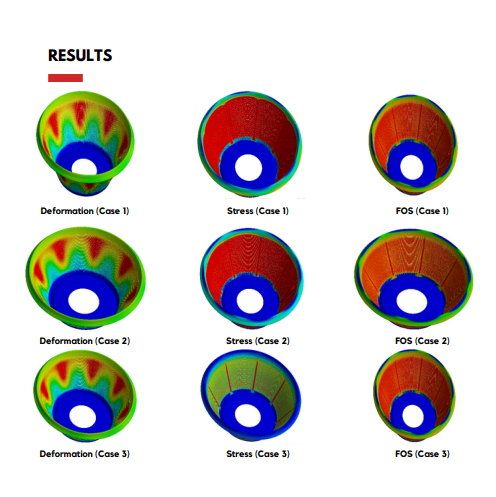

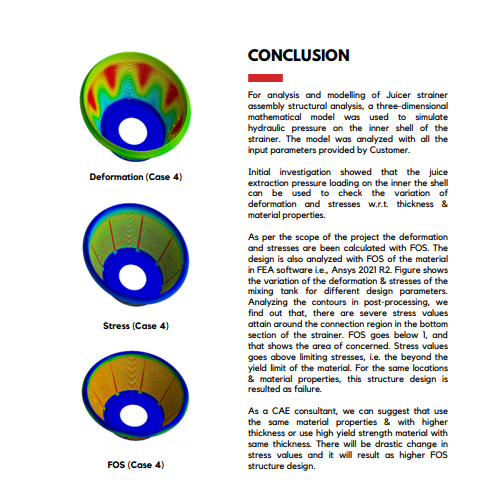

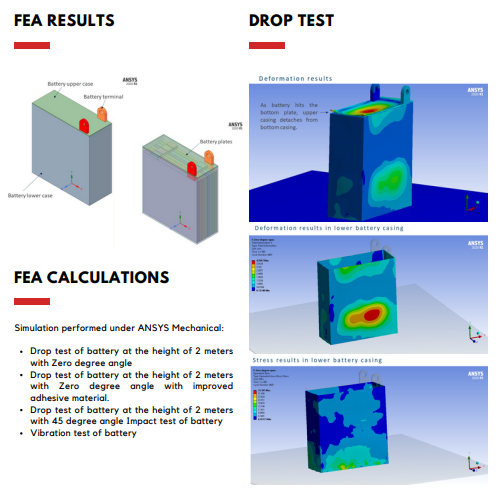

studies

Case

Explore Case Studies

Qantur Technologies is a pioneer engineering simulations company based in Gurgaon –India. We provides expert Computer Aided Engineering – CAE consulting services for engineering / product design analysis by modeling & simulation.

Download Case Study

Transform Ideas into Reality—Explore Our Simulation Solutions Today!

Partner with Us to Revolutionize Engineering Excellence!

Testimonials

Customer Testimonials

Bengal Industries Pvt. Ltd

The ANSYS Mechanical training conducted by Qantur Technologies was highly informative and helped our engineers resolve critical challenges in contact modeling, meshing, and fatigue analysis. The sessions were well-coordinated, delivered on schedule, and supported with patient guidance by the trainer and account manager. We truly value Qantur’s expertise, professionalism, and post-sales support.

Bengal Industries Pvt. Ltd

Bliss Anand Pvt. Ltd.

During our evaluation of CFD solutions, Qantur Technologies stood out for their technical expertise, reliability, and customer-focused approach. Their consulting projects achieved 98% accuracy compared to experimental values, instilling strong confidence in their capabilities. Based on this experience, we selected them as our preferred partner for ANSYS software, consulting, training, and support. We highly recommend their services to organizations with simulation requirements.

Bliss Anand Pvt. Ltd.

CUET, Department of Mechanical Engineering

We experienced significant value from Qantur Technologies’ expertise in ANSYS solutions, particularly in FEA and CFD consulting. Their skilled engineers provided insightful training on geometry, meshing, and modeling, which enhanced our students’ and faculty’s analytical skills. With exceptional support and patience from their trainers, we are pleased to recommend Qantur Technologies for ANSYS implementation, training, and advanced simulation services.

CUET, Department of Mechanical Engineering

Entecnia Consulting Pvt. Ltd.

Our collaboration with Qantur Technologies for ANSYS implementation and consulting has been outstanding. Their commitment, technical expertise, and timely support in FEA and CFD have added significant value to our engineering and R&D teams. The exclusive 15-day training session further enhanced our team’s analytical skills, and we truly appreciate their professionalism and ownership in managing the entire process seamlessly. We highly recommend Qantur Technologies for advanced CAE solutions.

Entecnia Consulting Pvt. Ltd.

Flovel Energy Pvt. Ltd.

Our experience with Qantur Technologies in implementing ANSYS HPC and CFD solutions has been remarkable. Their skilled engineers conducted in-depth training for our R&D team, equipping us with advanced methods to simulate hydro turbines and enhance component performance. Their reliable support, technical expertise, and resource assistance make them a trusted partner for ANSYS software, consulting, and training. We highly recommend Qantur Technologies for any ANSYS-related services.

Flovel Energy Pvt. Ltd.

Flovel Energy Pvt. Ltd.

We truly value the ANSYS SpaceClaim training conducted by Qantur Technologies at our R&D center. The course was tailored to our requirements, highly informative, and supported by hands-on workshops that enhanced our team’s modeling skills. Their application engineer was proactive, helpful, and ensured customization aligned with our needs. We look forward to engaging Qantur Technologies again for future application-based trainings.

Flovel Energy Pvt. Ltd.

IoTechWorld Avigation Pvt. Ltd.

At IoTechWorld, we develop advanced drones for agriculture, survey, and surveillance, and ANSYS Mechanical & CFD have been instrumental in optimizing our designs. Qantur Technologies supported us with the right resources, training, and technical expertise to address complex FEA & CFD challenges. Their team’s commitment and knowledge have empowered us to innovate faster and more effectively. We highly recommend Qantur Technologies for ANSYS implementation, consulting, and support.

IoTechWorld Avigation Pvt. Ltd.

Karman Drones Pvt. Ltd.

Our collaboration with Qantur Technologies for At Karman Drones, innovation drives our mission in AI-powered autonomous drones. Qantur Technologies has been a key partner in implementing ANSYS software, providing outstanding FEA & CFD expertise, consulting, and hands-on training. Their engineers have empowered our team with advanced simulation knowledge, improving design validation, performance optimization, and overall efficiency. We highly recommend Qantur Technologies for their exceptional support and technical proficiency.

Karman Drones Pvt. Ltd.

Mittal Electronics

At Mittal Electronics, innovation and R&D are at the heart of our product development. Partnering with Qantur Technologies for ANSYS FEA & CFD has been transformative—helping us accelerate design validation, optimize performance, and tackle complex engineering challenges with confidence. Their expert training, consulting, and quick response have greatly strengthened our engineering capabilities. We look forward to continued collaboration with Qantur Technologies.

Mittal Electronics

MV Electrosystems Pvt. Ltd.

At MV Electrosystems, innovation in rail transportation demands precision and reliability. Partnering with Qantur Technologies for ANSYS ICEPAK & Mechanical has significantly enhanced our ability to optimize product design, improve efficiency, and accelerate development. Their expert training, technical guidance, and hands-on support in FEA & CFD not only strengthened our engineering skills but also deepened our understanding of core physics. We truly value this collaboration and highly recommend Qantur Technologies for simulation-driven innovation.

MV Electrosystems Pvt. Ltd.

Nicotra India Pvt. Ltd.

At Nicotra India, precision in fan design is critical. Qantur Technologies has been a valuable partner, providing quick and responsive CFD support—both onsite and online—that helped us validate designs and solve complex meshing and model setup challenges. Their extensive training sessions empowered our R&D team with practical simulation expertise, strengthening our analytical and design capabilities. We are pleased with their services and highly recommend them for ANSYS implementation and technical support.

Nicotra India Pvt. Ltd.

NTF (India) Pvt. Ltd.

At NTF India, we rely on advanced engineering solutions to deliver world-class automotive components. Qantur Technologies has been a trusted partner, supporting us with ANSYS implementation and in-depth FEA analysis for our key projects. Their professionalism, technical expertise, and ability to deliver under challenging conditions have consistently exceeded our expectations. We highly value their commitment and look forward to continued collaboration on future product development initiatives.

NTF (India) Pvt. Ltd.

Onassis Auto Limited

At Onassis Auto, precision and reliability are at the core of our automotive components. With Qantur Technologies’ guidance in Ansys Mechanical, we have successfully enhanced our engineering capabilities, optimized transmission components, and improved efficiency. Their hands-on training, prompt support, and expertise in FEA have greatly empowered our R&D team. We are pleased to recommend Qantur Technologies for their outstanding technical services and commitment.

Onassis Auto Limited

P2P Analysis & Solutions

At P2P Analysis & Solutions, innovation is our core, and Qantur Technologies has been an invaluable partner in this journey. Their technical excellence in Ansys Mechanical and LS-DYNA, coupled with meticulous training and proactive support, has empowered our team to solve complex challenges with confidence. Their professionalism, collaborative approach, and customer-centric commitment make them a trusted long-term partner. We strongly recommend Qantur Technologies for any Ansys-related solutions and services.

P2P Analysis & Solutions

S&O Marintime

S&O Marintime