Products

Ansys optiSLang Process Integration & Design Optimization

Revolutionize product performance with cutting-edge mechanical simulation tools

BETTER PRODUCT IN LESS TIME Parametric Design Studies Made Easy

Ansys optiSLang is a constantly evolving, leading-edge answer to the challenges posed by CAE-based Robust Design Optimization (RDO). Its state-of-the-art algorithms efficiently and automatically search for the most robust design configuration, eliminating the slow, manual process that used to define RDO. With optiSLang as your process integration and design optimization solution, you’ll make the right decisions sooner.

- Process Automation

- Design of Experiments & Sensitivity Analysis

- Optimization & Uncertainty Quantification

- Ansys Minerva Integration

Features

Quick Specs

Accelerate searches for the best and most robust design configuration by automating the search process with interactive visualization and AI technologies. State-of-the-art algorithms for design exploration, optimization, robustness and reliability analysis let you make better decisions with less effort using design optimization software.

Still have a question?

Process Automation

Simulation Workflow Building

Optimization

Robust Design

Design of Experiments

Model Calibration

Reduced-Order Modeling

CAx Connectors

Ansys Minerva Integration

Ansys optiSLang License

The Ansys optiSLang premium and enterprise licensing categories allow you to choose what fits your needs best. The premium offering will enable users access to a broad simulation workflow automation and optimization capabilities. Any user requires an enterprise license to build apps and conduct a much higher number of concurrent variations. The optiSLang AI+ add-on allows leveraging AI for metamodeling, and can be added to the Pro, Premium or Enterprise packages.

Mechanical Pro

Mechanical Premium

Mechanical Enterprise

AI+

Design Studies

Classic DOE

Sampling & Sensitivity Analysis

Robust Design Optimization

Classic scalar meta-modeling

Reliability Analysis

UQ for signals, 2D/3D

Process Integration and Workflow Orchestration

Embedded in Ansys + LS-OPT*

Build and automate workflows

Integrate 3rd party tools

App generation

Advanced Meta Modeling

Field meta-modeling (signals, 2D/3D)

Advanced meta-modeling for scalars

Concurrent Solver Variant Licensing

Solver variations for parametric design study

+3

+7

Capabilities

Streamline and automate your RDO process with leading-edge AI and interactive visualization

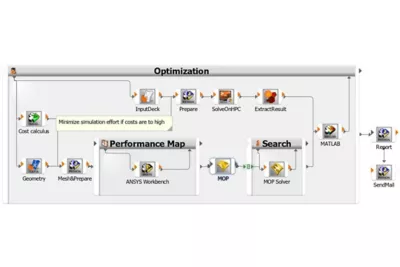

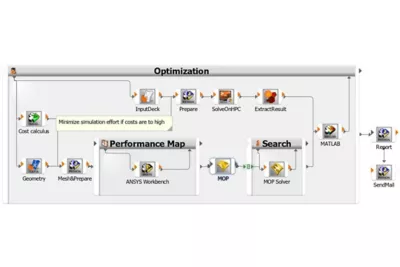

Ansys optiSLang is a process integration and design optimization solution that automates key aspects of the robust design optimization process. optiSLang connects multiple CAx tools and different physics into a holistic, multi-disciplinary approach to optimization. Additionally, it enables simulations processes to be standardized and shared, giving new hires and simulation novices more direct access to simulation. With this powerful toolset, your entire team of engineers and designers can gain a better, more complete understanding of their design and make the right decisions sooner.

Capabilities

Key Features

OptiSLang supports integration with a variety of CAx programs and offers powerful RDO tools to gain critical insights faster

Orchestrate and Automate

Orchestrate and Automate

Orchestrate and Automate

Orchestrate and Automate

Understand and Optimize

Understand and Optimize

Understand and Optimize

Understand and Optimize Equip your engineers with tools that help improve product designs beyond what human brains can perceive. This could mean tweaking several hundred design parameters, figuring out the parameter subset that makes a huge impact on product performance and optimizing the design.

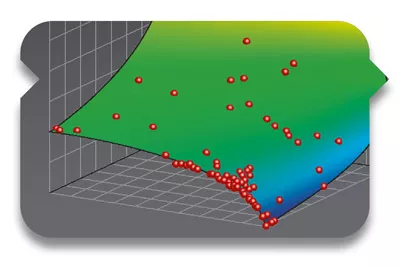

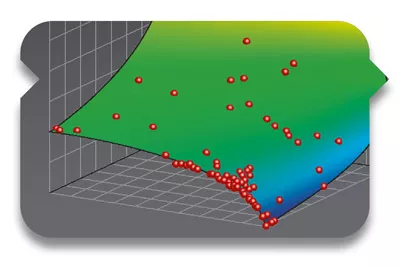

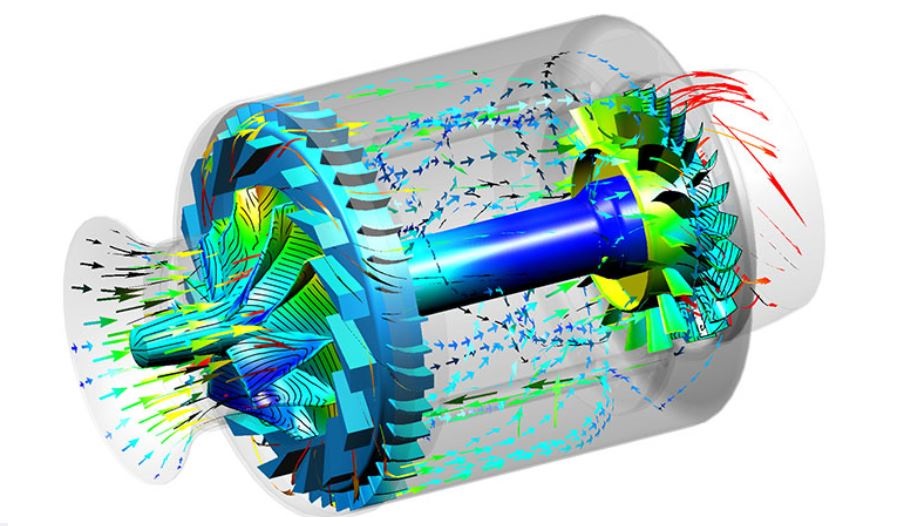

Simulation plays a big role in understanding products and processes, especially complex ones. Parameter-based variation analysis gives you insight into how your design behaves under variability. Multidisciplinary optimization tasks often require a huge number of variables, and it can be difficult to know where to focus. optiSLang’s algorithms and correlation analysis automatically identify the most salient variables, reducing the number of design variables you must worry about. The program’s sensitivity analysis also creates the basis to appropriately formulate the optimization task with respect to choice and number of objectives or possible constraints, helping you quickly zero in on the best approximation model.

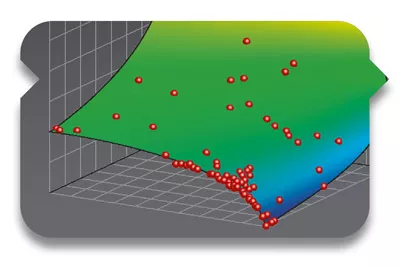

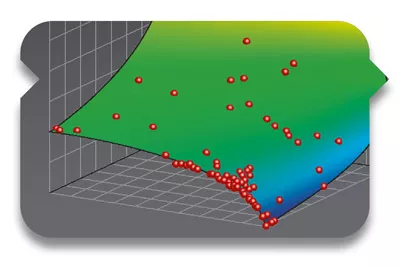

Reduced Order Modeling — Ansys optiSLang builds metamodels for rapid feedback and robust design analysis in a fraction of the time it would take to run a simulation to predict a certain design.

Design optimization and parameter identification — Ansys optiSLang’s powerful algorithms and automated workflows build on earlier steps of sensitivity analysis to provide a wizard-driven decision tree to recommend the optimizer with default settings.

optiSLang AI+ — Empowers simulation users with advanced machine learning methods for sensitivity analysis, optimization, and robust design. A more efficient approach offering higher quality prediction of CAE results gives engineers a better understanding of the causal relationship between design parameters and product performance. Design better products in less time.

Ansys Minerva Integrationl

Ansys Minerva Integrationl

Ansys Minerva Integrationl

Ansys Minerva Integrationl One of the major challenges of today’s CAE engineers is the increasing complexity of processes while results have to be delivered in shorter times. At the same time, within the engineering process, multiple disciplines like NVH, thermal-mechanical-electrical analyses, safety evaluation, tolerance management and costs have to be considered. Improving one discipline could require a compromise in others.

To allow cooperation in multiphysical simulation and multidisciplinary optimization, the automation and publishing of workflows for several repetitive tasks, as well as simulation data management become essential, like:

- Transfer of results of one discipline as input into the next step of operation

- Post-processing steps, reports and result extraction

- Model generation tasks

- Variants comparison for finding an optimal design

- Subsequent optimization runs with adapted constraints and objectives

A powerful solution to overcome these challenges is the combination of Ansys optiSLang and Ansys Minerva.

Evaluate Robustness

Evaluate Robustness

Evaluate Robustness

Evaluate Robustness Quantify and minimize the uncertainty of risk going from simulation to real-world production when it comes to unexpected manufacturing tolerances and other real-world environmental factors.

Similar to sensitivity analysis, robustness analysis identifies the most important scattering variables and offers a decision tree to select the most appropriate algorithms to verify robustness and reliability for your product or situation. This is key for designs that must meet high safety or quality requirements with event probabilities of less than 1 out of 1,000. A reliability analysis can quantify the probability of exceeding a limit and prove it to be less than the accepted value. optiSLang’s powerful algorithms help ensure product quality, minimizing scrap, recall and the risk of legal action.

Robust Design and Reliability

Robust Design and Reliability

Robust Design and Reliability

Robust Design and Reliability Product performance is often subject to scattering properties due to manufacturing tolerances, material scatter and other stochastic effects. Stochastic analysis and statistical methods like optiSLang’s are key to ensuring product quality.

Similar to sensitivity analysis, robustness analysis identifies the most important scattering variables and offers a decision tree to select the most appropriate algorithms to verify robustness and reliability for your product or situation. This is key for designs that have to meet high safety or quality requirements with event probabilities of less than 1 out of 1,000. A reliability analysis can quantify the probability of exceeding a limit and prove it to be less than the accepted value. optiSLang’s powerful algorithms help ensure product quality, minimizing scrap, recall and the risk of legal action.

Design Optimization And Parameter Identification (Calibration)

Design Optimization And Parameter Identification (Calibration)

Design Optimization And Parameter Identification (Calibration)

Design Optimization And Parameter Identification (Calibration) Ansys optiSLang’s powerful algorithms and automated workflows build on the earlier steps of sensitivity analysis to provide a wizard-driven decision tree to recommend the optimizer with default setting.

The optiSLang program determines the optimal design parameters for various multidisciplinary, non-linear and multicriteria optimization tasks. Based on the earlier steps of sensitivity analysis, optiSLang has already identified the most relevant parameters and can perform a pre-optimization on the chosen metamodel. Its wizard-based interface provides user guidance to recommend the optimizer from available algorithms such as gradient-based methods, adaptive response surface method and more, including custom optimization algorithms. You can even forward optimal design candidates from one loop to the next to streamline and standardize your work.

Robust Design and Reliability

Robust Design and Reliability

Robust Design and Reliability

Robust Design and Reliability Product performance is often subject to scattering properties due to manufacturing tolerances, material scatter and other stochastic effects. Stochastic analysis and statistical methods like optiSLang’s are key to ensuring product quality.

Similar to sensitivity analysis, robustness analysis identifies the most important scattering variables and offers a decision tree to select the most appropriate algorithms to verify robustness and reliability for your product or situation. This is key for designs that have to meet high safety or quality requirements with event probabilities of less than 1 out of 1,000. A reliability analysis can quantify the probability of exceeding a limit and prove it to be less than the accepted value. optiSLang’s powerful algorithms help ensure product quality, minimizing scrap, recall and the risk of legal action.

Visioneering

Recent Events & Webinars

Discover how engineering simulation is expanding across the entire product lifecycle.

Ansys Multiphysics

Conference

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Future Tech Expo 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Ansys Multiphysics

Conference

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Visioneering

Blogs & Trends

Discover how engineering simulation is expanding across the entire product lifecycle. engineering / product design analysis by modeling & simulation.

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Innovate

Breaking News & White Paper

Discover how engineering simulation is expanding across the entire product lifecycle.

Smart Strategies for Large Structural Simulations

One way to gauge the progress of engineering simulation software is through the lens of size. Engineers today routinely run structural simulations with a few million degrees of freedom, and the largest commercial structural simulations have topped even 100 million degrees of freedom.

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

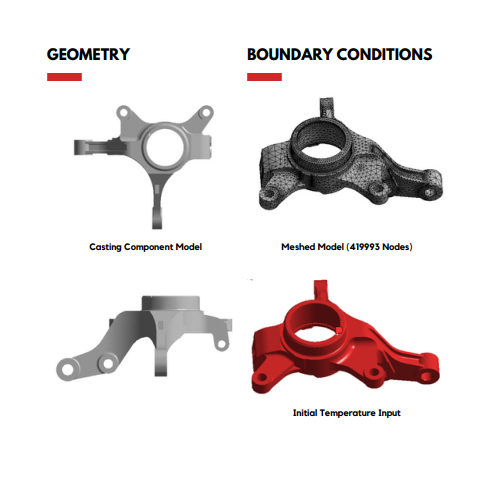

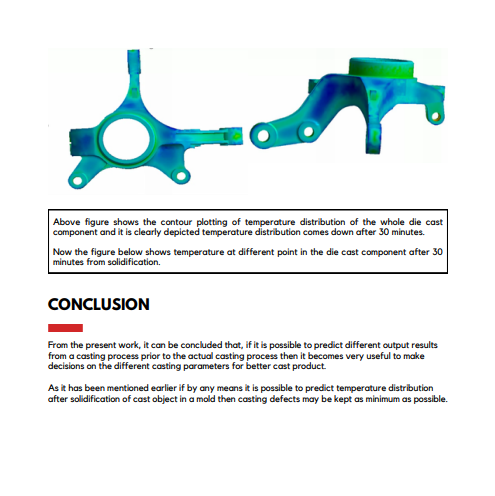

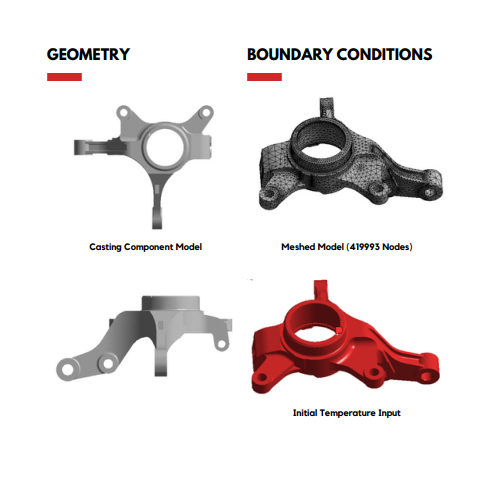

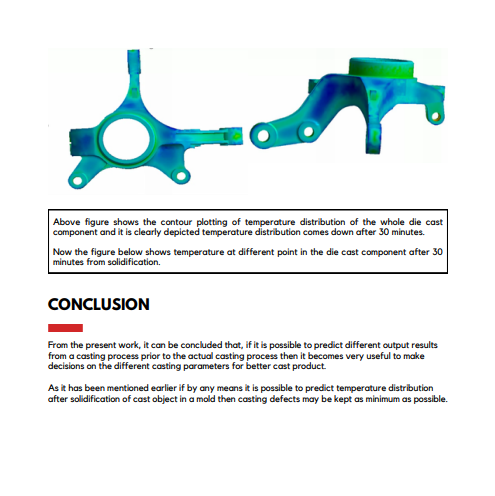

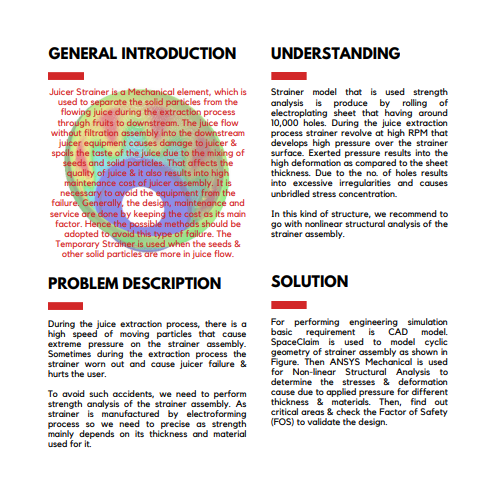

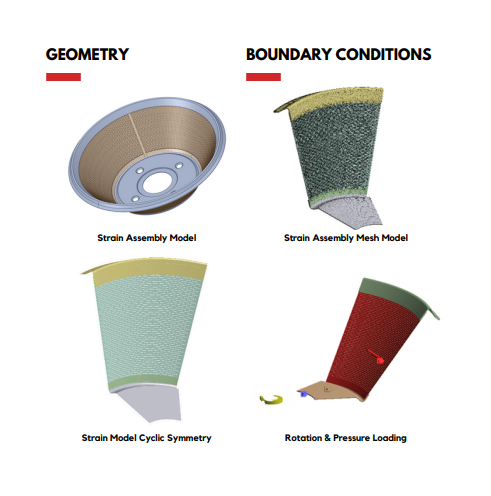

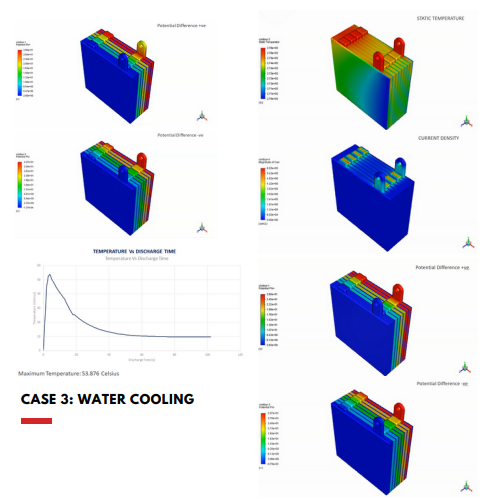

Studies

Case

Explore Case Studies

Qantur Technologies is a pioneer engineering simulations company based in Gurgaon –India. We provides expert Computer Aided Engineering – CAE consulting services for engineering / product design analysis by modeling & simulation.

Download Case Study

Transform Ideas into Reality—Explore Our Simulation Solutions Today!

Partner with Us to Revolutionize Engineering Excellence!

Testimonials

Customer Testimonials

Bengal Industries Pvt. Ltd

The ANSYS Mechanical training conducted by Qantur Technologies was highly informative and helped our engineers resolve critical challenges in contact modeling, meshing, and fatigue analysis. The sessions were well-coordinated, delivered on schedule, and supported with patient guidance by the trainer and account manager. We truly value Qantur’s expertise, professionalism, and post-sales support.

Bengal Industries Pvt. Ltd

Bliss Anand Pvt. Ltd.

During our evaluation of CFD solutions, Qantur Technologies stood out for their technical expertise, reliability, and customer-focused approach. Their consulting projects achieved 98% accuracy compared to experimental values, instilling strong confidence in their capabilities. Based on this experience, we selected them as our preferred partner for ANSYS software, consulting, training, and support. We highly recommend their services to organizations with simulation requirements.

Bliss Anand Pvt. Ltd.

CUET, Department of Mechanical Engineering

We experienced significant value from Qantur Technologies’ expertise in ANSYS solutions, particularly in FEA and CFD consulting. Their skilled engineers provided insightful training on geometry, meshing, and modeling, which enhanced our students’ and faculty’s analytical skills. With exceptional support and patience from their trainers, we are pleased to recommend Qantur Technologies for ANSYS implementation, training, and advanced simulation services.

CUET, Department of Mechanical Engineering

Entecnia Consulting Pvt. Ltd.

Our collaboration with Qantur Technologies for ANSYS implementation and consulting has been outstanding. Their commitment, technical expertise, and timely support in FEA and CFD have added significant value to our engineering and R&D teams. The exclusive 15-day training session further enhanced our team’s analytical skills, and we truly appreciate their professionalism and ownership in managing the entire process seamlessly. We highly recommend Qantur Technologies for advanced CAE solutions.

Entecnia Consulting Pvt. Ltd.

Flovel Energy Pvt. Ltd.

Our experience with Qantur Technologies in implementing ANSYS HPC and CFD solutions has been remarkable. Their skilled engineers conducted in-depth training for our R&D team, equipping us with advanced methods to simulate hydro turbines and enhance component performance. Their reliable support, technical expertise, and resource assistance make them a trusted partner for ANSYS software, consulting, and training. We highly recommend Qantur Technologies for any ANSYS-related services.

Flovel Energy Pvt. Ltd.

Flovel Energy Pvt. Ltd.

We truly value the ANSYS SpaceClaim training conducted by Qantur Technologies at our R&D center. The course was tailored to our requirements, highly informative, and supported by hands-on workshops that enhanced our team’s modeling skills. Their application engineer was proactive, helpful, and ensured customization aligned with our needs. We look forward to engaging Qantur Technologies again for future application-based trainings.

Flovel Energy Pvt. Ltd.

IoTechWorld Avigation Pvt. Ltd.

At IoTechWorld, we develop advanced drones for agriculture, survey, and surveillance, and ANSYS Mechanical & CFD have been instrumental in optimizing our designs. Qantur Technologies supported us with the right resources, training, and technical expertise to address complex FEA & CFD challenges. Their team’s commitment and knowledge have empowered us to innovate faster and more effectively. We highly recommend Qantur Technologies for ANSYS implementation, consulting, and support.

IoTechWorld Avigation Pvt. Ltd.

Karman Drones Pvt. Ltd.

Our collaboration with Qantur Technologies for At Karman Drones, innovation drives our mission in AI-powered autonomous drones. Qantur Technologies has been a key partner in implementing ANSYS software, providing outstanding FEA & CFD expertise, consulting, and hands-on training. Their engineers have empowered our team with advanced simulation knowledge, improving design validation, performance optimization, and overall efficiency. We highly recommend Qantur Technologies for their exceptional support and technical proficiency.

Karman Drones Pvt. Ltd.

Mittal Electronics

At Mittal Electronics, innovation and R&D are at the heart of our product development. Partnering with Qantur Technologies for ANSYS FEA & CFD has been transformative—helping us accelerate design validation, optimize performance, and tackle complex engineering challenges with confidence. Their expert training, consulting, and quick response have greatly strengthened our engineering capabilities. We look forward to continued collaboration with Qantur Technologies.

Mittal Electronics

MV Electrosystems Pvt. Ltd.

At MV Electrosystems, innovation in rail transportation demands precision and reliability. Partnering with Qantur Technologies for ANSYS ICEPAK & Mechanical has significantly enhanced our ability to optimize product design, improve efficiency, and accelerate development. Their expert training, technical guidance, and hands-on support in FEA & CFD not only strengthened our engineering skills but also deepened our understanding of core physics. We truly value this collaboration and highly recommend Qantur Technologies for simulation-driven innovation.

MV Electrosystems Pvt. Ltd.

Nicotra India Pvt. Ltd.

At Nicotra India, precision in fan design is critical. Qantur Technologies has been a valuable partner, providing quick and responsive CFD support—both onsite and online—that helped us validate designs and solve complex meshing and model setup challenges. Their extensive training sessions empowered our R&D team with practical simulation expertise, strengthening our analytical and design capabilities. We are pleased with their services and highly recommend them for ANSYS implementation and technical support.

Nicotra India Pvt. Ltd.

NTF (India) Pvt. Ltd.

At NTF India, we rely on advanced engineering solutions to deliver world-class automotive components. Qantur Technologies has been a trusted partner, supporting us with ANSYS implementation and in-depth FEA analysis for our key projects. Their professionalism, technical expertise, and ability to deliver under challenging conditions have consistently exceeded our expectations. We highly value their commitment and look forward to continued collaboration on future product development initiatives.

NTF (India) Pvt. Ltd.

Onassis Auto Limited

At Onassis Auto, precision and reliability are at the core of our automotive components. With Qantur Technologies’ guidance in Ansys Mechanical, we have successfully enhanced our engineering capabilities, optimized transmission components, and improved efficiency. Their hands-on training, prompt support, and expertise in FEA have greatly empowered our R&D team. We are pleased to recommend Qantur Technologies for their outstanding technical services and commitment.

Onassis Auto Limited

P2P Analysis & Solutions

At P2P Analysis & Solutions, innovation is our core, and Qantur Technologies has been an invaluable partner in this journey. Their technical excellence in Ansys Mechanical and LS-DYNA, coupled with meticulous training and proactive support, has empowered our team to solve complex challenges with confidence. Their professionalism, collaborative approach, and customer-centric commitment make them a trusted long-term partner. We strongly recommend Qantur Technologies for any Ansys-related solutions and services.

P2P Analysis & Solutions

S&O Marintime

S&O Marintime