Products

End-to-End Multiphysics and Multiscale Simulation Platform

The sounds a product makes directly impact on user experiences. Sounds create strong emotions — positively or negatively — that reinforce brand identity. The difficulty of predicting acoustic results means that a single engineering mistake can prove costly to the final product, making Ansys Acoustics Analysis a powerful solution to ensure optimal acoustics and a successful end product.

Features

Ansys Acoustics Analysis High Level Features

Ansys Acoustics Analysis helps optimize sound from the first steps of product development. By applying this acoustic modeling software, you can have best-in-class tools at the ready to deliver top-quality user experiences that blend optimal functionality with pristine acoustics. By predicting the acoustic effects of a given product configuration at the earliest stage of design, you maximize your acoustic benefits while minimizing time, costs and rework. Test and validate the future soundscape of your product, such as electric vehicles, via simulation to ensure the desired acoustic experience.

Still have a question?

Products

Acoustic Simulation Products

Qantur Technologies is a pioneer engineering simulations company based in Gurgaon –India. We provides expert Computer Aided Engineering – CAE consulting services for engineering / product design analysis by modeling & simulation.

By coupling multiphysics simulation with acoustic testing results, predict and fine-tune product acoustics at an early stage while making improvements along the way.

- Sound analysis and acoustic calculation

- Sound quality with psychoacoustic criteria

- Active sound design for EV and ICE engines

- Listen to acoustic CAE Simulations

- Sound perception through jury testing

- 3D sound simulator

Capabilities

Capabilities

Discover multiple aspects of your products’ acoustic properties through in-depth testing, simulating and analyzing, all with the goal of improving a final design early in the development process.

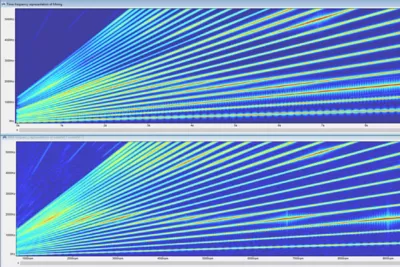

Listen to and Analyze Sound Quality

Listen to and Analyze Sound Quality

Listen to and Analyze Sound Quality

Listen to and Analyze Sound Quality Ansys Mechanical covers all your needs for linear dynamic analysis, including modal, harmonic, spectrum response and random vibration with pre-stress, along with advanced solver options for rapid solutions.

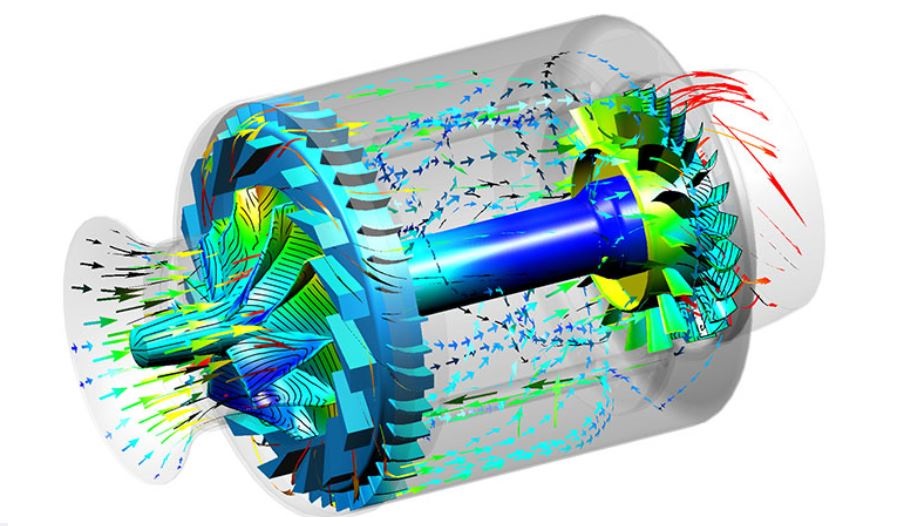

Carry out acoustics simulations to understand the vibroacoustic behavior of systems, with or without structural pre-loading. Including pre-loading adds more fidelity and means that self-weighted, bolted assemblies — or even squealing brakes — can be simulated.

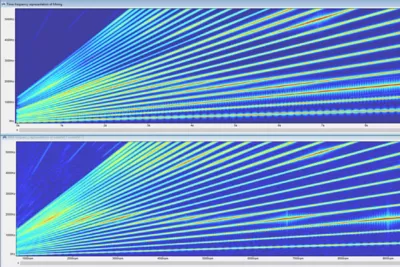

Optimize Engine Sound for E-Motor

Optimize Engine Sound for E-Motor

Optimize Engine Sound for E-Motor

Optimize Engine Sound for E-Motor Moving beyond linear, elastic materials, you can simulate the behavior of materials as they undergo plastic or even hyperelastic deformation (materials like rubber and neoprene).

Nonlinear simulation also takes into account contact and large deflection of parts moving around relative to each other, either with or without friction.

Listen to Mechanical and Fluids Simulations

Listen to Mechanical and Fluids Simulations

Listen to Mechanical and Fluids Simulations

Listen to Mechanical and Fluids Simulations Ansys Mechanical includes a comprehensive range of contact capabilities that enable you to account for the interactions of multiple parts.

It can simulate everything from a bonded contact that treats joints between parts as if they are glued or welded together to contact interfaces that allow parts to move apart and together with or without frictional effects. Being able to simulate contact correctly means that you can simulate the change in load paths when parts deform and confidently predict how assemblies will behave in the real world.

Evaluate Sound Perception with Jury Testing

Evaluate Sound Perception with Jury Testing

Evaluate Sound Perception with Jury Testing

Evaluate Sound Perception with Jury Testing Ansys Mechanical includes parametric, shape (mesh morphing) and topology optimization. Any model in Ansys Mechanical can be used to drive a parametric optimization.

Any model in Ansys Mechanical can be used to drive a parametric optimization. Shape and topology optimization capabilities allow creation of efficient geometries, which can be taken back to CAD for production or further simulation work. Additive manufacturing, lightweighting and robust design are excellent use cases for this technology.

Active Sound Design for Automotive

Active Sound Design for Automotive

Active Sound Design for Automotive

Active Sound Design for Automotive Simulating heat conduction, convection and radiation across assemblies enables you to predict the temperature of components, which can then be used to examine induced stresses and deformations.

With Ansys Mechanical, you can read in power losses or calculated temperatures from other analysis systems or files, which means that CFD or electromagnetic simulations can be a starting point for thermal analysis. It is also possible to account for fluid flow through pipes and heat generated from friction between parts. All these capabilities give you more accurate simulations and better results.

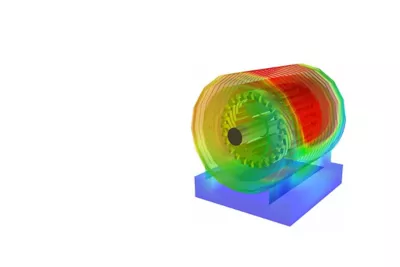

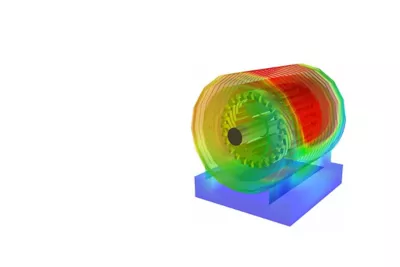

From Component-level Acoustic Simulation to System-level Sound Rendering

From Component-level Acoustic Simulation to System-level Sound Rendering

From Component-level Acoustic Simulation to System-level Sound Rendering

From Component-level Acoustic Simulation to System-level Sound Rendering A range of material models covering everything from hyperelastics, shape-memory alloys, soils, concrete, plastic and metallic structures can be accurately modeled in Mechanical.

You can also add user-defined material models, if needed. Granta Materials Data for Simulation provides instant, clickable access to the materials property data you need, eliminating data search time and input errors. Material Designer can easily create representative volume elements (RVE’s) based around lattice, fiber, weave or user-created geometries to facilitate multiscale modeling of complex material structures.

Visioneering

Recent Events & Webinars

Discover how engineering simulation is expanding across the entire product lifecycle.

Ansys Multiphysics

Conference

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Future Tech Expo 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Ansys Multiphysics

Conference

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Visioneering

Blogs & Trends

Discover how engineering simulation is expanding across the entire product lifecycle. engineering / product design analysis by modeling & simulation.

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Innovate

Breaking News & White Paper

Discover how engineering simulation is expanding across the entire product lifecycle.

Smart Strategies for Large Structural Simulations

One way to gauge the progress of engineering simulation software is through the lens of size. Engineers today routinely run structural simulations with a few million degrees of freedom, and the largest commercial structural simulations have topped even 100 million degrees of freedom.

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

studies

Case

Explore Case Studies

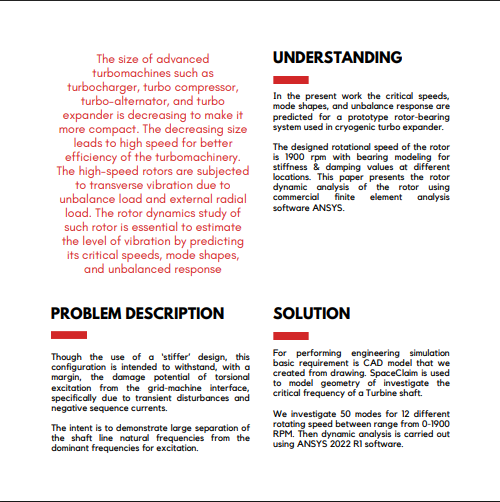

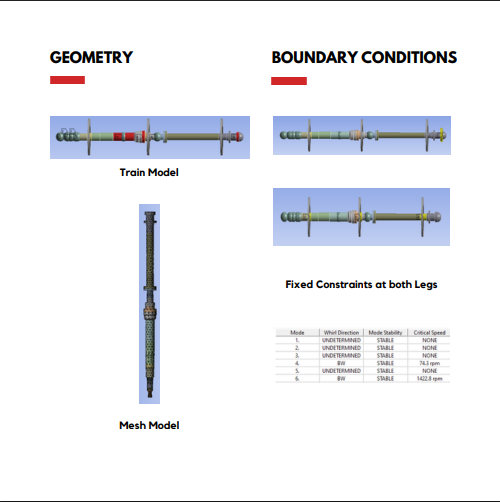

Qantur Technologies is a pioneer engineering simulations company based in Gurgaon –India. We provides expert Computer Aided Engineering – CAE consulting services for engineering / product design analysis by modeling & simulation.

Download Case Study

Transform Ideas into Reality—Explore Our Simulation Solutions Today!

Partner with Us to Revolutionize Engineering Excellence!

Testimonials

Customer Testimonials

Bengal Industries Pvt. Ltd

The ANSYS Mechanical training conducted by Qantur Technologies was highly informative and helped our engineers resolve critical challenges in contact modeling, meshing, and fatigue analysis. The sessions were well-coordinated, delivered on schedule, and supported with patient guidance by the trainer and account manager. We truly value Qantur’s expertise, professionalism, and post-sales support.

Bengal Industries Pvt. Ltd

Bliss Anand Pvt. Ltd.

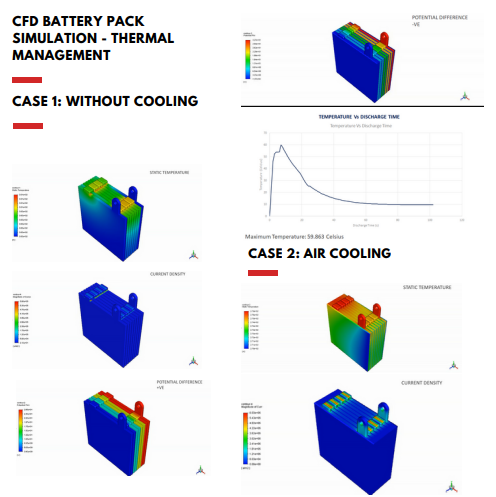

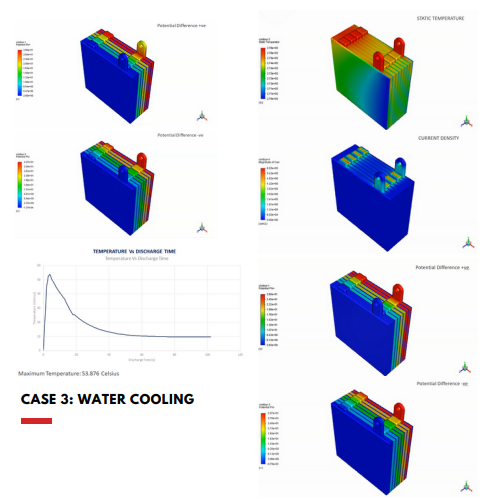

During our evaluation of CFD solutions, Qantur Technologies stood out for their technical expertise, reliability, and customer-focused approach. Their consulting projects achieved 98% accuracy compared to experimental values, instilling strong confidence in their capabilities. Based on this experience, we selected them as our preferred partner for ANSYS software, consulting, training, and support. We highly recommend their services to organizations with simulation requirements.

Bliss Anand Pvt. Ltd.

CUET, Department of Mechanical Engineering

We experienced significant value from Qantur Technologies’ expertise in ANSYS solutions, particularly in FEA and CFD consulting. Their skilled engineers provided insightful training on geometry, meshing, and modeling, which enhanced our students’ and faculty’s analytical skills. With exceptional support and patience from their trainers, we are pleased to recommend Qantur Technologies for ANSYS implementation, training, and advanced simulation services.

CUET, Department of Mechanical Engineering

Entecnia Consulting Pvt. Ltd.

Our collaboration with Qantur Technologies for ANSYS implementation and consulting has been outstanding. Their commitment, technical expertise, and timely support in FEA and CFD have added significant value to our engineering and R&D teams. The exclusive 15-day training session further enhanced our team’s analytical skills, and we truly appreciate their professionalism and ownership in managing the entire process seamlessly. We highly recommend Qantur Technologies for advanced CAE solutions.

Entecnia Consulting Pvt. Ltd.

Flovel Energy Pvt. Ltd.

Our experience with Qantur Technologies in implementing ANSYS HPC and CFD solutions has been remarkable. Their skilled engineers conducted in-depth training for our R&D team, equipping us with advanced methods to simulate hydro turbines and enhance component performance. Their reliable support, technical expertise, and resource assistance make them a trusted partner for ANSYS software, consulting, and training. We highly recommend Qantur Technologies for any ANSYS-related services.

Flovel Energy Pvt. Ltd.

Flovel Energy Pvt. Ltd.

We truly value the ANSYS SpaceClaim training conducted by Qantur Technologies at our R&D center. The course was tailored to our requirements, highly informative, and supported by hands-on workshops that enhanced our team’s modeling skills. Their application engineer was proactive, helpful, and ensured customization aligned with our needs. We look forward to engaging Qantur Technologies again for future application-based trainings.

Flovel Energy Pvt. Ltd.

IoTechWorld Avigation Pvt. Ltd.

At IoTechWorld, we develop advanced drones for agriculture, survey, and surveillance, and ANSYS Mechanical & CFD have been instrumental in optimizing our designs. Qantur Technologies supported us with the right resources, training, and technical expertise to address complex FEA & CFD challenges. Their team’s commitment and knowledge have empowered us to innovate faster and more effectively. We highly recommend Qantur Technologies for ANSYS implementation, consulting, and support.

IoTechWorld Avigation Pvt. Ltd.

Karman Drones Pvt. Ltd.

Our collaboration with Qantur Technologies for At Karman Drones, innovation drives our mission in AI-powered autonomous drones. Qantur Technologies has been a key partner in implementing ANSYS software, providing outstanding FEA & CFD expertise, consulting, and hands-on training. Their engineers have empowered our team with advanced simulation knowledge, improving design validation, performance optimization, and overall efficiency. We highly recommend Qantur Technologies for their exceptional support and technical proficiency.

Karman Drones Pvt. Ltd.

Mittal Electronics

At Mittal Electronics, innovation and R&D are at the heart of our product development. Partnering with Qantur Technologies for ANSYS FEA & CFD has been transformative—helping us accelerate design validation, optimize performance, and tackle complex engineering challenges with confidence. Their expert training, consulting, and quick response have greatly strengthened our engineering capabilities. We look forward to continued collaboration with Qantur Technologies.

Mittal Electronics

MV Electrosystems Pvt. Ltd.

At MV Electrosystems, innovation in rail transportation demands precision and reliability. Partnering with Qantur Technologies for ANSYS ICEPAK & Mechanical has significantly enhanced our ability to optimize product design, improve efficiency, and accelerate development. Their expert training, technical guidance, and hands-on support in FEA & CFD not only strengthened our engineering skills but also deepened our understanding of core physics. We truly value this collaboration and highly recommend Qantur Technologies for simulation-driven innovation.

MV Electrosystems Pvt. Ltd.

Nicotra India Pvt. Ltd.

At Nicotra India, precision in fan design is critical. Qantur Technologies has been a valuable partner, providing quick and responsive CFD support—both onsite and online—that helped us validate designs and solve complex meshing and model setup challenges. Their extensive training sessions empowered our R&D team with practical simulation expertise, strengthening our analytical and design capabilities. We are pleased with their services and highly recommend them for ANSYS implementation and technical support.

Nicotra India Pvt. Ltd.

NTF (India) Pvt. Ltd.

At NTF India, we rely on advanced engineering solutions to deliver world-class automotive components. Qantur Technologies has been a trusted partner, supporting us with ANSYS implementation and in-depth FEA analysis for our key projects. Their professionalism, technical expertise, and ability to deliver under challenging conditions have consistently exceeded our expectations. We highly value their commitment and look forward to continued collaboration on future product development initiatives.

NTF (India) Pvt. Ltd.

Onassis Auto Limited

At Onassis Auto, precision and reliability are at the core of our automotive components. With Qantur Technologies’ guidance in Ansys Mechanical, we have successfully enhanced our engineering capabilities, optimized transmission components, and improved efficiency. Their hands-on training, prompt support, and expertise in FEA have greatly empowered our R&D team. We are pleased to recommend Qantur Technologies for their outstanding technical services and commitment.

Onassis Auto Limited

P2P Analysis & Solutions

At P2P Analysis & Solutions, innovation is our core, and Qantur Technologies has been an invaluable partner in this journey. Their technical excellence in Ansys Mechanical and LS-DYNA, coupled with meticulous training and proactive support, has empowered our team to solve complex challenges with confidence. Their professionalism, collaborative approach, and customer-centric commitment make them a trusted long-term partner. We strongly recommend Qantur Technologies for any Ansys-related solutions and services.

P2P Analysis & Solutions

S&O Marintime

S&O Marintime