Industries

Aerospace and Defence

Simulating the Future of Transportation and Mobility

Exponentially innovate to deliver the transportation and mobility experiences of the future with the next generation of simulation and engineering tools.

Cut costs & innovate

quickly with simulation

The aerospace and defence industry represents the pinnacle of technological advancement, driving innovation in aviation, space exploration, and military applications. This sector encompasses a wide range of activities, from designing advanced aircraft and spacecraft to developing sophisticated defence systems. Ansys offers essential tools such as Ansys Mechanical for structural analysis, Ansys Fluent for fluid dynamics and heat transfer, Ansys CFX for computational fluid dynamics of turbomachinery, Ansys HFSS for electromagnetic field simulations of communication equipment, Ansys LS-DYNA for impact and blast simulations, and Ansys Maxwell for electric motor and actuator design. These solutions enable engineers to tackle complex challenges in aerodynamics, structural integrity, thermal management, and communication systems, pushing the boundaries of what is possible in aerospace and defence technology.

- Electric Vehicles

- Vehicle Engineering

- Simulation Solutions

- ADAS & Autonomous Vehicles

Advanced Military Technology Development

ANSYS solutions for Advanced Military Technology Development enable high-fidelity simulation of complex defense systems across land, sea, air, and space. They support rapid innovation, mission readiness, and performance under extreme conditions.

Structural simulations to predict the component behaviour and ensure durability under extreme loading conditions.

Thermal analysis to assess thermal stresses and prevent overheating of components in various environments.

Electromagnetic analysis of communication and navigation systems to enhance signal clarity and effective performance.

Explicit dynamics to simulate blasts and impacts to improve the design of missile systems.

Component-Level Capabilities

ANSYS Component-Level Capabilities for Advanced Military Technology Development provide detailed simulation of critical parts such as sensors, propulsion systems, and electronics. These tools ensure performance, durability, and reliability in demanding defense applications.

Armour and Protective Structures

- Simulate ballistic impacts to enhance armour effectiveness and improve protection.

- Conduct thermal analysis to evaluate the behaviour of armour under extreme temperatures, ensuring effective performance.

Weapon Systems

- Perform structural analysis to evaluate the durability and performance of weapon systems under dynamic forces and operational stress.

- Simulate fluid dynamics to optimize the design of propulsion and exhaust systems, enhancing the performance and efficiency of weapon systems.

Stealth Technology

- Perform radar cross-section (RCS) calculations and predict far-field radar Conduct electromagnetic simulations on radar absorbent materials (RAM) to ensure maximum effectiveness in reducing visibility.

Communication Systems

- Perform signal integrity analysis to optimize data transmission in communication systems and reduce signal noise.

- Conduct electromagnetic compatibility and interference (EMC/EMI) analysis to maintain reliable communication.

Propulsion Systems

- Simulate the thermal behaviour of components to optimize heat dissipation and ensure propulsion system durability under extreme temperatures.

- Perform structural and fatigue analysis to optimize component design for improved performance and long-term reliability.

Relevant Ansys Software

Relevant ANSYS software for Advanced Military Technology Development includes ANSYS HFSS, Mechanical, Fluent, and LS-DYNA to simulate electromagnetics, structural integrity, fluid dynamics, and impact resistance. These tools accelerate innovation and ensure performance in mission-critical environments.

Design of Aircraft and Drones

ANSYS solutions for the design of aircraft and drones provide advanced simulation tools for aerodynamics, structural integrity, propulsion, and control systems. They help optimize performance, reduce development time, and ensure safety and compliance.

Aerodynamic simulations to optimize lift and drag for better flight performance and reduced fuel consumption.

Structural analysis to ensure the airframe can withstand operational loads and extreme conditions.

Vibration and fatigue simulations to ensure the long-term reliability of aircraft structures during repeated use.

Thermal and heat transfer analysis to ensure efficient cooling of avionics, engines, and sensitive components.

Electromagnetic analysis to ensure effective and safe operation of electronic systems and prevent interference.

Component-Level Capabilities

ANSYS Component-Level Capabilities for the Design of Aircraft and Drones enable precise simulation of parts like wings, rotors, sensors, and propulsion systems. These tools ensure optimal performance, reliability, and lightweight design in aerospace applications.

Wings and Airfoils

- Simulate aerodynamics to optimize lift and drag for enhanced performance and manoeuvrability.

- Analyze structural strength to ensure wings can withstand dynamic loads, during takeoff, flight, and landing.

Fuselage

- Test the structural integrity of the fuselage to ensure durability and safety during all phases of flight.

- Perform thermal analysis on insulation blankets to maintain interior comfort for passengers and crew.

Landing Gear

- Perform explicit dynamics to simulate impacts to ensure the landing gear can withstand heavy forces during landing.

- Analyze wear and tear to ensure long-term reliability and reduce maintenance costs.

Avionics

- Evaluate electromagnetic interference (EMI) to ensure avionics systems function safely without disruption.

- Evaluate embedded software performance to ensure reliability and safety in avionics systems under varying conditions.

Propulsion Systems

- Simulate combustion processes to optimize fuel efficiency and reduce emissions across different operational conditions.

- Perform thermal analysis to manage heat dissipation and thermal stresses, and ensure engine durability under extreme thermal loads.

Relevant Ansys Software

Relevant ANSYS software for Component-Level Capabilities in Aircraft and Drone Design includes ANSYS Fluent, Mechanical, HFSS, and CFX to simulate aerodynamics, structural loads, electromagnetics, and propulsion. These tools ensure high performance, safety, and efficiency in aerospace components.

Blast, Explosion, and Impact Simulation

ANSYS solutions for Blast, Explosion, and Impact Simulation provide high-fidelity modeling of extreme events to assess structural response and material behavior. These tools help enhance safety, survivability, and compliance in defense and industrial applications.

Explicit dynamics to simulate explosive impacts to assess damage potential on target structures.

Thermal analysis to evaluate temperature distribution and thermal stresses generated in components during extreme conditions.

Structural analysis to reinforce key components for enhanced blast resistance.

Component-Level Capabilities

ANSYS Component-Level Capabilities for Blast, Explosion, and Impact Simulation enable detailed analysis of how individual components respond to high-strain, shock, and pressure loads. These tools support the design of resilient systems for safety-critical applications.

Armour Panels

- Simulate ballistic and blast impacts using structural analysis to optimize armour for maximum protection against explosive threats.

- Perform thermal analysis to evaluate thermal stresses and ensure armour effectiveness in hostile environments.

Protective Barriers

- Test structural integrity of barriers using dynamic analysis to withstand high-force explosions while maintaining functionality.

- Simulate thermal effects on barrier components to ensure long-term durability under extreme conditions.

Vehicle Hulls

- Simulate blast impacts using structural analysis to assess survivability and ensure the protection of personnel and equipment.

- Conduct fatigue analysis to improve resilience under operational conditions, due to cyclic loading and vibrations.

Shock Absorbers

- Simulate shock absorber performance using structural analysis to optimize response and improve system effectiveness under explosive impacts.

- Analyze the durability and fatigue of shock absorption systems in artillery guns and heavy equipment for improved stability.

Missiles, Torpedoes, and Mines

- Simulate blast effects using explicit dynamics to assess the damage potential of missiles, torpedoes, and mines in combat scenarios.

- Test guidance system performance using electromagnetic simulations to optimize EMI/EMC characteristics and signal integrity for reliable functioning.

Relevant Ansys Software

Relevant ANSYS software for Blast, Explosion, and Impact Simulation includes ANSYS LS-DYNA, Autodyn, and Mechanical to model shock waves, material deformation, and structural failure. These tools ensure accurate prediction of damage and improve system resilience under extreme conditions.

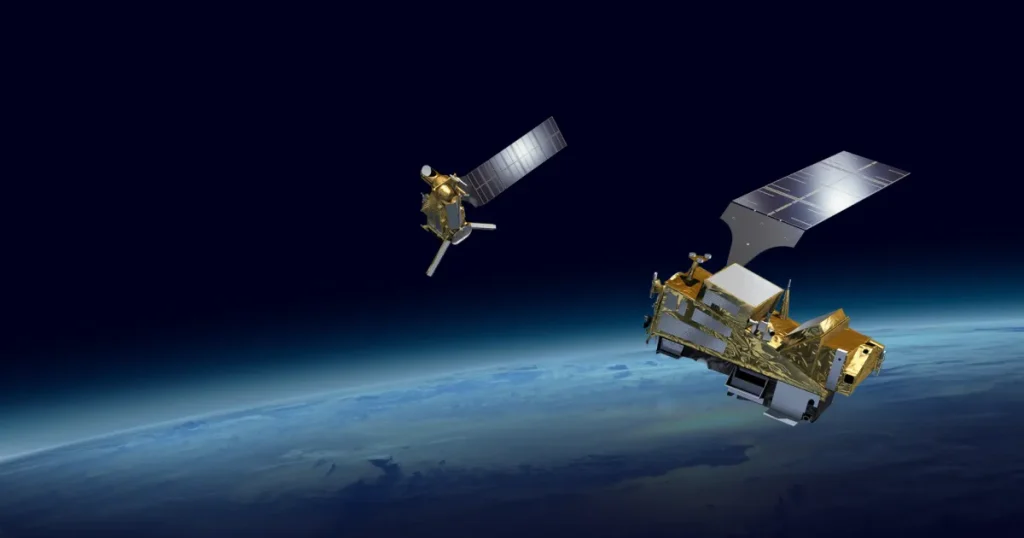

Spacecraft Analysis

ANSYS solutions for Spacecraft Analysis offer advanced simulation of structural, thermal, and electromagnetic performance in the harsh conditions of space. They help ensure mission reliability, system integrity, and optimal design for launch and orbit operations.

Thermal analysis to optimize heat resistance and thermal regulation of spacecraft during re-entry and space missions.

Structural analysis to ensure the spacecraft can withstand the extreme forces and conditions of space travel, including launch, in-orbit, and re-entry environments.

Vibration analysis to assess the effect of vibrations on spacecraft integrity and ensure reliable performance.

Electromagnetic simulations to ensure clear, reliable communication for data transmission and system control, minimizing interference and signal loss.

Component-Level Capabilities

ANSYS Component-Level Capabilities for Spacecraft Analysis enable detailed simulation of subsystems like antennas, thrusters, thermal protection, and avionics. These tools ensure precise performance, durability, and efficiency in extreme space environments.

Thermal Protection Systems

- Perform thermal analysis on components to assess their functioning during extreme temperatures.

- Structural simulations to assess the durability of thermal protection systems to withstand operational loads.

Transponders

- Analyze signal integrity to ensure efficient data transmission across long distances in space.

- Simulate electromagnetic performance to optimize signal transmission and minimize interference in transponder systems.

Satellite Structures

- Analyze structural strength to ensure satellite durability under the mechanical forces experienced during launch and orbital operations.

- Perform fatigue analysis to ensure long-term operational life of satellite components.

Solar Panels

- Simulate electrical performance to ensure the maximum efficiency of solar panels for power generation in space.

- Simulate micrometeoroid impacts to ensure solar panel resilience in the harsh environment of outer space.

Antennas

- Conduct electromagnetic analysis to ensure reliable communication across vast distances in space.

- Signal integrity analysis to ensure reliable signal transmission, minimizing data loss and distortion caused by interference.

Relevant Ansys Software

Relevant ANSYS software for Spacecraft Analysis includes ANSYS Mechanical, Fluent, HFSS, and Thermal Desktop to simulate structural loads, thermal behavior, fluid dynamics, and electromagnetic performance. These tools ensure mission success through accurate, end-to-end system analysis.

Explicit simulation for crash, impact, and nonlinear events

Radar and Antenna Design

ANSYS solutions for Radar and Antenna Design provide advanced electromagnetic simulation to optimize performance, range, and signal clarity. They support the development of high-efficiency, compact systems for aerospace, defense, and communication applications.

Electromagnetic analysis to optimize radar systems for detection accuracy and reliability in complex environments.

Structural analysis to evaluate the mechanical robustness of radar systems and antennas under operational stress, vibrations, and environmental factors.

Signal integrity analysis to minimize interference, ensure clear signal transmission, and enhance data accuracy in radar and communication systems.

Component-Level Capabilities

ANSYS Component-Level Capabilities for Radar and Antenna Design allow precise simulation of individual components such as antenna arrays, waveguides, and radar systems. These tools ensure optimal signal performance, efficiency, and integration in complex electromagnetic environments.

Radar Systems

- Simulate electromagnetic fields to ensure radar systems can detect targets with high accuracy.

- Test the structural integrity of radar components to ensure their functionality under operational stresses.

Antenna Arrays

- Generate radiation pattern results to analyze effectiveness in varied environments.

- Analyze signal integrity and EMI to ensure antenna array performance is unaffected by external interference and distortion.

Mounting Structures

- Test the structural strength of mounting systems to ensure antennas remain stable and functional in all conditions.

- Simulate vibrations to verify the performance stability of mounted systems.

Signal Processing Units

- Simulate signal integrity to ensure clear signal transmission and reliable communication.

- Evaluate electromagnetic interference (EMI) to prevent disruptions in signal integrity.

Relevant Ansys Software

Relevant ANSYS software for Radar and Antenna Design includes ANSYS HFSS, Maxwell, and Electronics Desktop to simulate electromagnetic performance, signal propagation, and antenna optimization. These tools ensure high-performance design and reliable operation in critical communication systems.

3D electromagnetic simulation for high-frequency componentsHFSS

Hypersonic Vehicle Design

ANSYS solutions for Hypersonic Vehicle Design enable high-fidelity simulation of aerodynamics, heat transfer, and structural integrity at extreme speeds. They help optimize vehicle performance, stability, and safety under the intense conditions of hypersonic flight.

Aerodynamics simulations for optimal flight performance at high speeds and extreme conditions.

Thermal analysis to evaluate the response of components due to high temperatures involved with high-speed flight.

Structural and vibrational analysis to ensure vehicle integrity and resistance to fatigue under dynamic loads.

Electromagnetic analysis of avionic systems for reliable navigation and communication at hypersonic speeds.

Component-Level Capabilities

ANSYS Component-Level Capabilities for Hypersonic Vehicle Design provide detailed simulation of individual components like thermal protection systems, propulsion, and materials. These tools ensure optimal performance, durability, and heat resistance in extreme hypersonic flight conditions.

Airframes

- Simulate aerodynamic forces to minimize drag and improve performance at hypersonic speeds.

- Perform thermal analysis to ensure the airframe can withstand extreme temperatures

Propulsion Systems

- Simulate combustion reactions to optimize propulsion for best performance while reducing fuel consumption.

- Perform thermal analysis to analyze thermal expansion and stresses in engine components during high-speed flight.

Control Surfaces

- Simulate the aerodynamics of control surfaces to maintain stability and manoeuvrability.

- Perform structural analysis to ensure the control surfaces can withstand extreme aerodynamic loading.

Avionics

- Utilize model-based simulation to verify and validate embedded software functionality for avionics systems, ensuring safety and performance compliance.

- Evaluate the reliability and life of electronic components subjected to mechanical shocks, vibrations, and thermal loads.

Relevant Ansys Software

Relevant ANSYS software for Hypersonic Vehicle Design includes ANSYS Fluent, Mechanical, and CFX to simulate aerodynamics, thermal management, and structural performance at hypersonic speeds. These tools help optimize vehicle design and ensure reliability in extreme flight conditions.

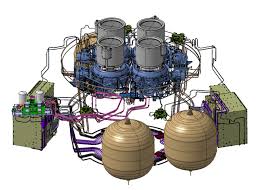

Advanced Propulsion Systems

ANSYS solutions for Advanced Propulsion Systems provide comprehensive simulation tools for optimizing engine performance, efficiency, and thermal management. These tools support the design of cutting-edge propulsion technologies for aerospace, automotive, and energy applications.

Thermal and heat transfer analysis to asses thermal expansion and optimize heat dissipation in advanced propulsion systems.

Fluid dynamics for optimal fuel and airflow management in engines and propulsion components.

Structural analysis to ensure durability and long-term performance under high stress and thermal load.

Vibration and fatigue analysis to optimize engine stability and enhance the operational life of components.

Conduct combustion reaction simulations to ensure efficient fuel burning and maintain performance during high-speed flight.

Component-Level Capabilities

ANSYS Component-Level Capabilities for Advanced Propulsion Systems enable detailed simulation of individual components like turbines, injectors, and combustion chambers. These tools optimize efficiency, durability, and performance under extreme operating conditions.

Jet Engines

- Simulate fluid dynamics for flow around the blades to enhance the performance of jet engines.

- Test structural strength and fatigue of engine components to ensure reliable performance and longevity under extreme conditions.

Rocket Engines

- Simulate combustion reactions to ensure efficient mixing and burning of fuel for effective thrust generation.

- Perform thermo-structural analysis on engine components to ensure reliable operation under extremely high temperatures.

Turbines

- Analyze fluid dynamics for flow around the blades of the turbine to maximize energy conversion efficiency.

- Simulate the structural strength of turbine blades to withstand operational stresses.

Nozzles

- Perform fluid dynamics analysis on nozzles to optimize thrust generation and minimize energy losses.

- Conduct thermal simulations to evaluate thermal expansion and stresses generated in the nozzle.

Fuel Tanks

- Perform structural analysis on the tank to ensure that it can withstand operational stresses including shock loads, impacts and vibration.

- Simulate the sloshing of fuel to assess its effect on the tank structure (fluid-structure interaction, or FSI).

Relevant Ansys Software

Relevant ANSYS software for Advanced Propulsion Systems includes ANSYS Fluent, Mechanical, and CFX to simulate fluid dynamics, thermal behavior, and structural integrity. These tools ensure optimal performance, efficiency, and reliability in propulsion system design and analysis.

Explicit simulation for crash, impact, and nonlinear events

interested in our Product or Solution

Still have a Question?

FAQ

How does ANSYS support the aerospace and defence industry?

ANSYS provides advanced simulation tools to design, analyze, and validate aircraft and defence systems, ensuring safety, performance, and compliance with strict industry regulations.

What types of aerospace simulations can ANSYS perform?

ANSYS offers simulations for aerodynamics (CFD), structural integrity, thermal performance, vibration analysis, and electromagnetic compatibility—critical for aircraft and spacecraft development.

Can ANSYS help reduce physical prototyping in aerospace projects?

Yes, ANSYS allows engineers to test designs virtually under realistic conditions, significantly reducing the need for costly and time-consuming physical prototypes.

Does ANSYS support aerospace certification requirements?

ANSYS helps streamline compliance with regulatory standards like FAA, EASA, and MIL-STD by providing accurate, traceable simulations and documentation.

How does ANSYS contribute to lightweight and fuel-efficient design?

ANSYS enables topology optimization, materials analysis, and multi-physics simulation to design lighter, stronger components—enhancing fuel efficiency and performance.

Transform Ideas into Reality—Explore Our Simulation Solutions Today!

Partner with Us to Revolutionize Engineering Excellence!

Testimonials