Products

Our

Structural Analysis & Simulation Software Solutions

Optimize performance, enhance durability, and ensure reliability with our cutting-edge structural analysis tool

Overview

Structural Analysis

Software

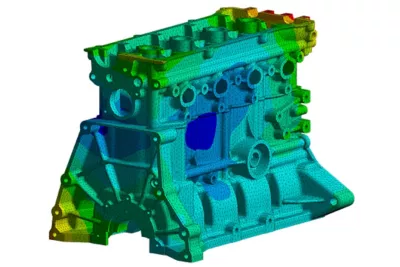

Ansys offers structural analysis software solutions that enable engineers of all levels and backgrounds to solve complex structural engineering problems faster and more efficiently. With our suite of tools, engineers can perform finite element analyses (FEA), customize and automate solutions for structural mechanics challenges and analyze multiple design scenarios. By using our software early in the design cycle, businesses can save costs, reduce the number of design cycles and bring products to market faster.Having seamless capabilities to connect easily to other physics analysis, ANSYS structural analysis software is used throughout the industry to optimize design.

Products

Our Structures Products

Qantur Technologies is a pioneer engineering simulations company based in Gurgaon –India. We provides expert Computer Aided Engineering – CAE consulting services for engineering / product design analysis by modeling & simulation.

Solve broad structural analysis needs with a suite of finite element analysis (FEA) solutions that provides in-depth analysis of structural and coupled-field behaviors.

- Easy to Use, Multi-Purpose Tool.

- Persistent, Dependable Solver Technology

- Dynamic, Integrated Platform

Engage with a powerful, explicit simulation tool with integration into Ansys Mechanical. A large array of capabilities and material models enable complex models with great scalability.

- Tackle simulations that are highly nonlinear

- Simulate extreme deformation problems

- Solve multiphysics problems with Incompressible CFD (ICFD), Electromagnetics (EM) and CESE /Compressible CFD and Chemistry solvers

Capabilities

Structures Capabilities

Easily handle the complexity of varied design environments with a range of analytical tools that enable you to meet performance goals and ensure long-term reliability.

Workbench

Workbench

Workbench

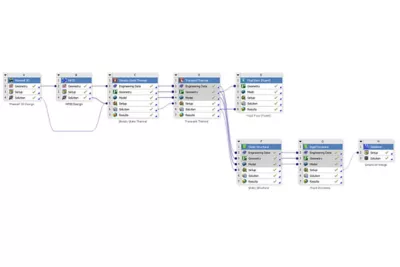

Workbench Workbench enables connections between analysis systems. For example, a prestressed modal analysis or fluid structure analysis.

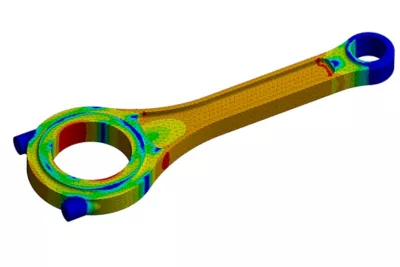

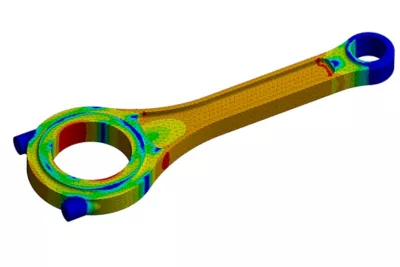

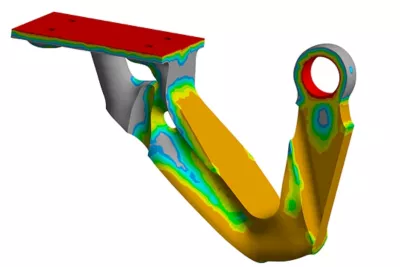

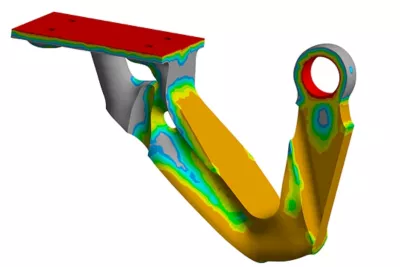

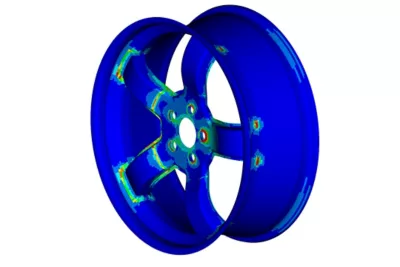

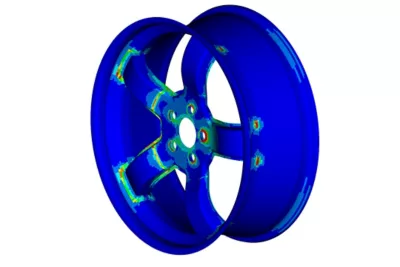

Strength Analysis

Strength Analysis

Strength Analysis

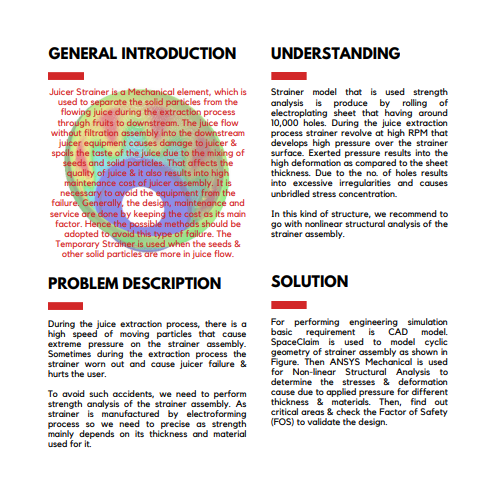

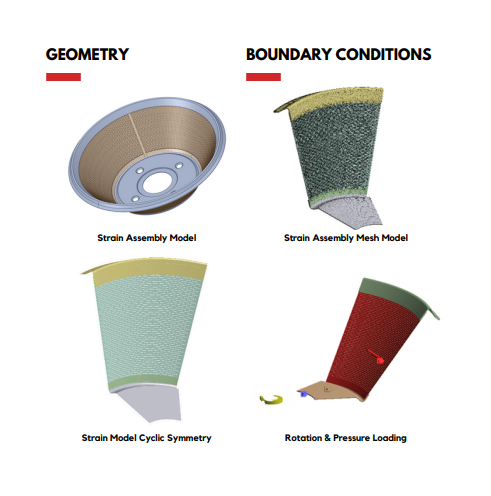

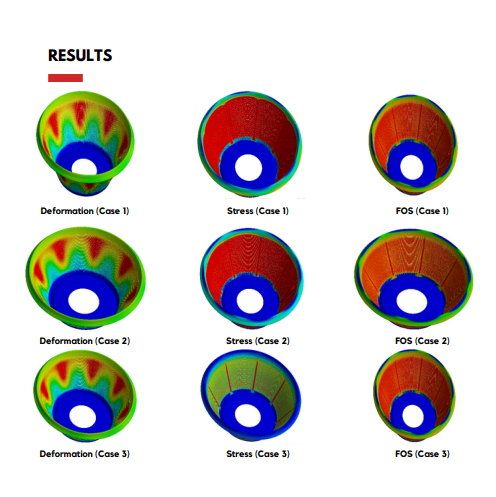

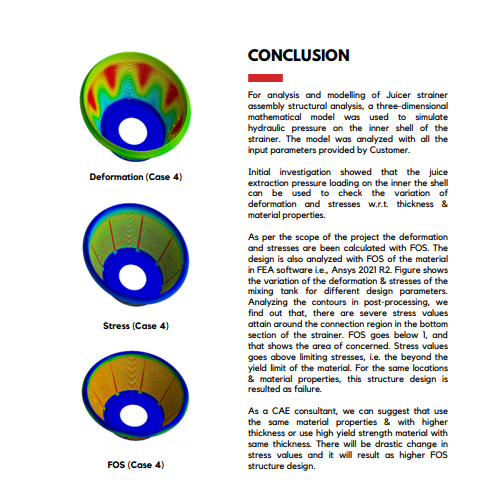

Strength Analysis The strength of components sits as a key requirement in understanding a product’s performance, lifecycle and possible failure modes.

Mechanical loading, thermal stress, bolt tension, pressure conditions and rotational acceleration are just some of the factors that dictate strength requirements for materials and designs. Our products ensure your product’s viability and safety by predicting the strength required for the loads your design will experience in service.

Vibration

Vibration

Vibration

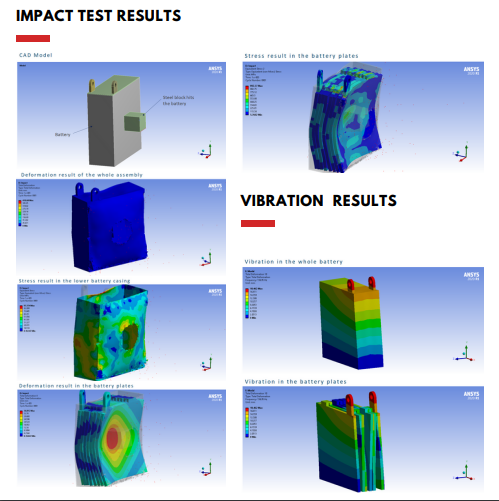

Vibration Vibration can be an undesired side effect of poor product design or the environment in which the product is operating.

It can have a substantial impact on durability and fatigue, leading to a shorter service life. You need to understand how your designs will respond to vibrations from phenomena such as brake squeal, earthquakes, transport and acoustic and harmonic loads to predict the behavior of products and components. Structural simulations can provide this understanding and help you to overcome your toughest vibration challenges.

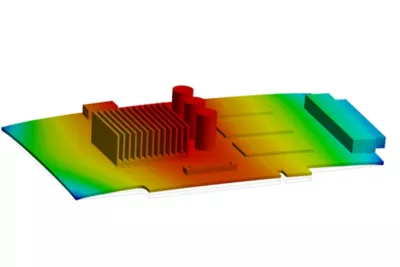

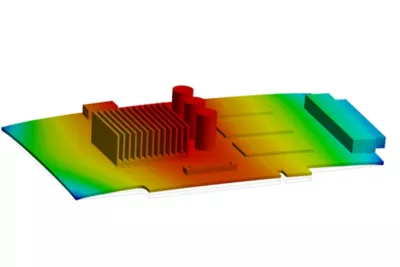

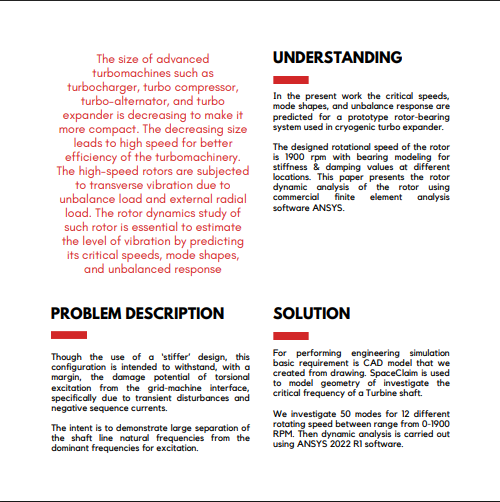

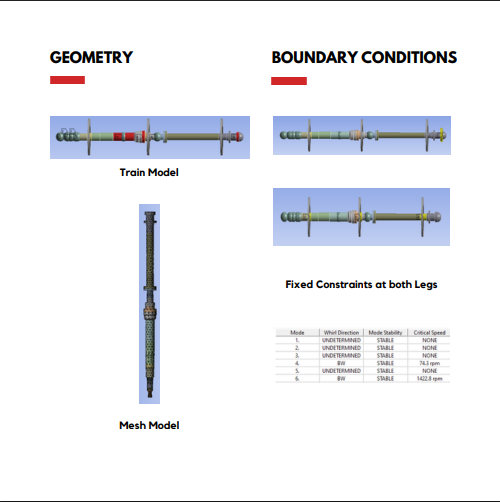

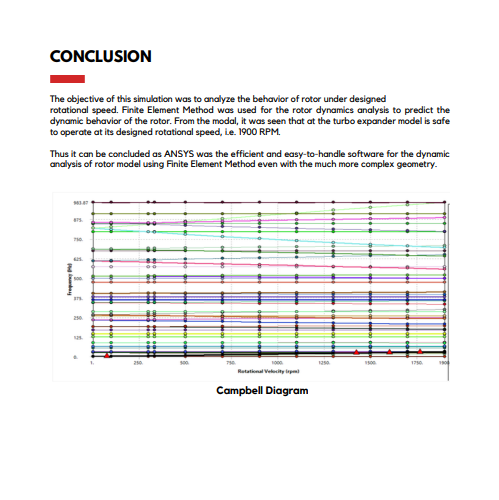

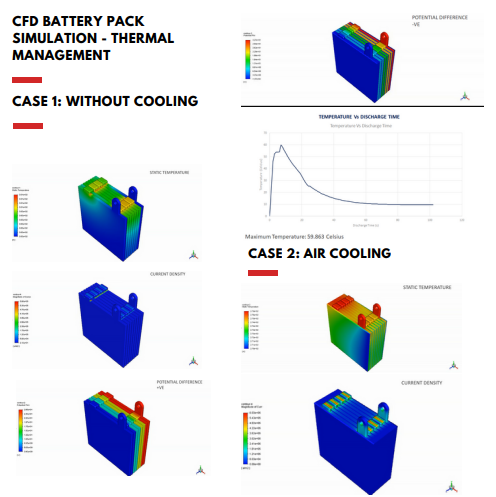

Thermal Analysis

Thermal Analysis

Thermal Analysis

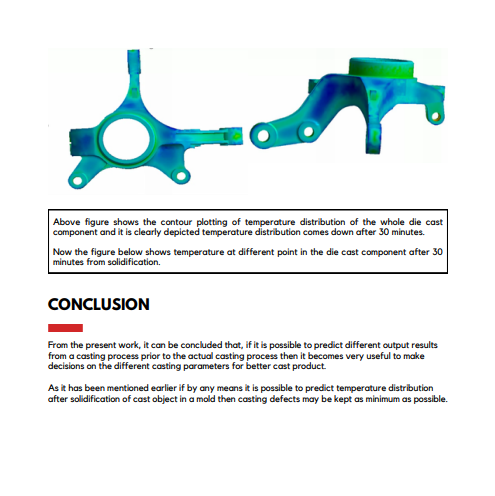

Thermal Analysis The effects of heat and thermal management on parts and assemblies is becoming increasingly critical as performance limits are pushed further by the need to have lighter, smaller and more efficient designs.

Convection, radiation and conduction loads are obvious, but the need to include the effect of power losses and thermal energy from friction and external sources such as pipe flows means that analysts need to have more tools at their disposal to simulate thermal models accurately.

Durability

Durability

Durability

Durability Building durable products is key to reducing warranty costs and increasing reliability. Being able to understand how designs will behave over time as load cycles increase helps you avoid unexpected failures.

Fatigue or lifing analysis is a key enabler in building this product durability knowledge.

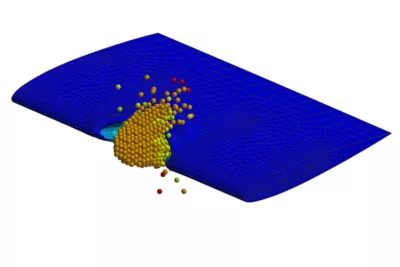

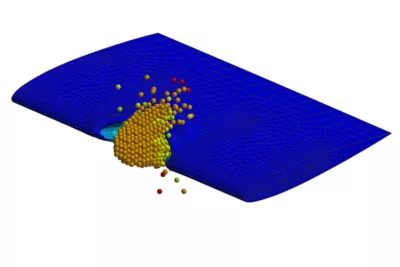

Impact

Impact

Impact

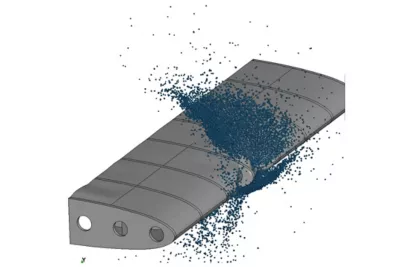

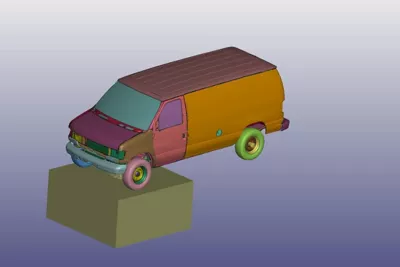

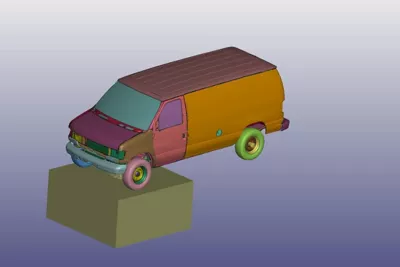

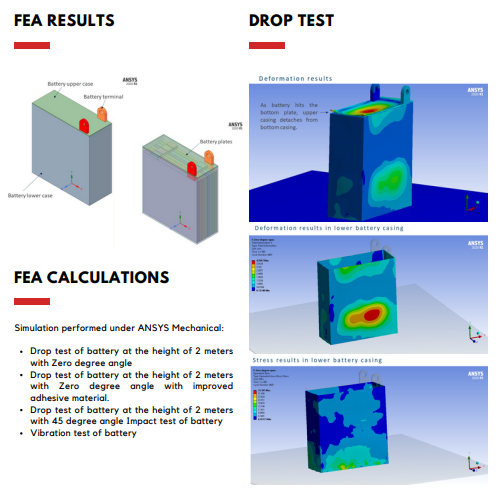

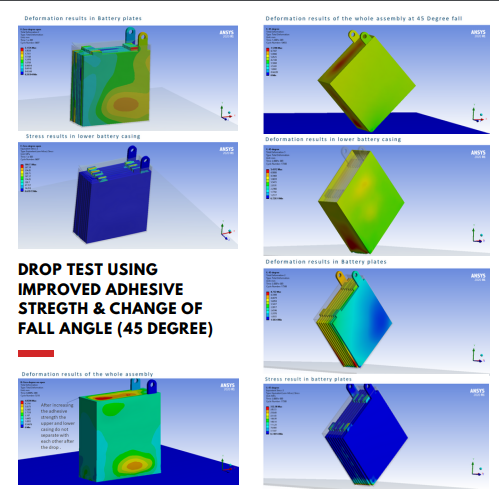

Impact Impact between two or more bodies is modeled by the Ansys structural family of programs, including mechanical, explicit dynamics and rigid body dynamics.

Drop tests are ideal candidates for an impact analysis. These impact analysis programs calculate the forces between two or more colliding bodies and the resultant deformation or damage.

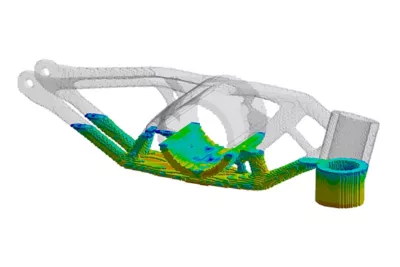

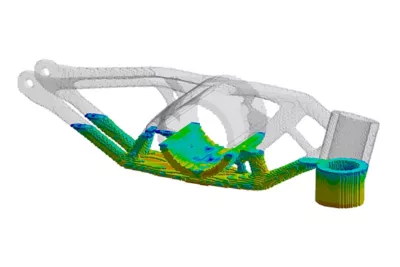

Structural Optimization

Structural Optimization

Structural Optimization

Structural Optimization Ansys optimization technology includes parametric, shape (mesh morphing) and topology optimization.

It enables you specify where supports and loads are located on your model and lets the software explore the design space. For example, you can easily perform lightweighting of structures, extract CAD shapes quickly and explore designs and process parameters for additive manufacturing.

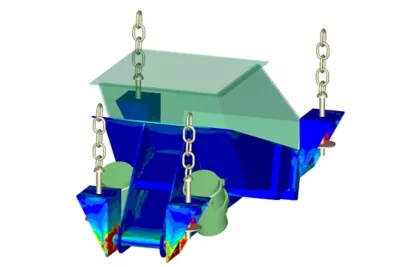

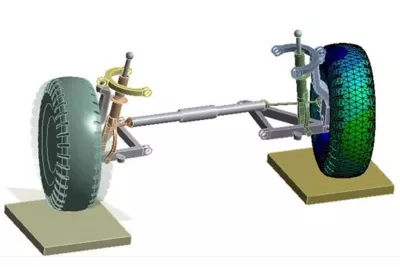

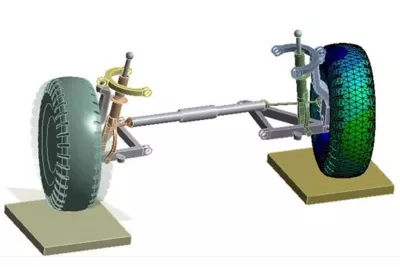

Rigid and Multi Body Dynamics

Rigid and Multi Body Dynamics

Rigid and Multi Body Dynamics

Rigid and Multi Body Dynamics Mechanical devices can contain complex assemblies of interconnected parts undergoing large overall motions.

Examples could include suspension assembles in ground vehicles, robotic manipulators in manufacturing processes or gear systems within electric drivetrains. Simulating the motion of these systems gives insight into their performance over the range of dynamic loading experienced when in operation.

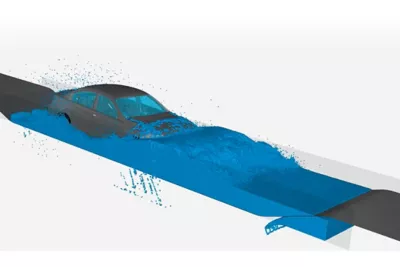

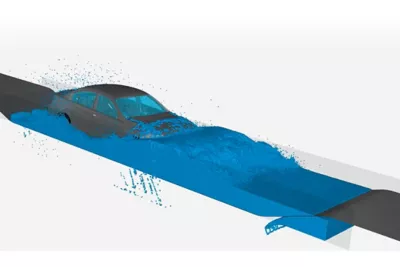

Hydrodynamics

Hydrodynamics

Hydrodynamics

Hydrodynamics Offshore structures are subjected to environmental loading from the effects of waves, currents and wind.

The design requirements for these structures can be quite different from traditional land-based constructions. Simulating the loading and the effects of these factors on structural response is a necessary component of the design. Ansys provides capabilities that can reproduce these loading conditions and responses across a broad range of applications. Ansys has solutions for different requirements depending on the specific application, from simplified models for truss type structures to high-fidelity simulations that include all aspects of the fluid loading environment.

Composites

Composites

Composites

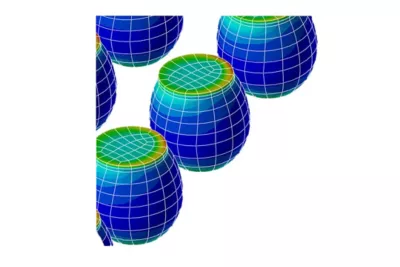

Composites The light, strong and versatile properties of composite materials make them attractive for many types of manufacturing.

Composite materials like carbon fiber, typically used in the aerospace and automotive sectors, are being used increasingly in energy, sports, construction and marine applications. Their composite nature, however, makes accurate simulation a challenge. Ansys offers a complete suite of tools to help you overcome this challenge.

Additive Manufacturing

Additive Manufacturing

Additive Manufacturing

Additive Manufacturing Ansys Additive Solution delivers the critical insights required by designers, engineers and analysts for a successful Additive Manufacturing Process, to avoid build failures and create parts that accurately conform to design specifications.

This comprehensive solution spans the entire workflow — from design for additive manufacturing (DfAM) through validation, print design, process simulation and material analysis.

Multiphysics

Multiphysics

Multiphysics

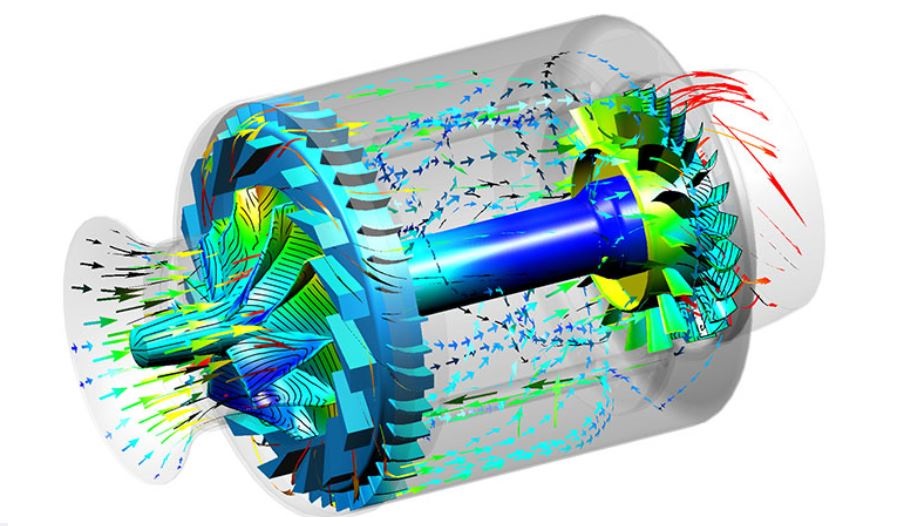

Multiphysics A vast range of multiphysics capabilities from simple thermal structural analysis to coupled field analyses using finite element analyses are available.

Our entire Ansys portfolio looks at the effects of electromagnetic, structural, fluid and thermal forces in combination. As a result, it predicts product performance with greater accuracy and provides seamless data transfer between physics solutions.

Visioneering

Recent Events & Webinars

Discover how engineering simulation is expanding across the entire product lifecycles.

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Visioneering

Blogs & Trends

Discover how engineering simulation is expanding across the entire product lifecycle. engineering / product design analysis by modeling & simulation.

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus aliquam enim urna, etiam. Mauris

Innovate

Breaking News & White Paper

Discover how engineering simulation is expanding across the entire product lifecycle.

Smart Strategies for Large Structural Simulations

One way to gauge the progress of engineering simulation software is through the lens of size. Engineers today routinely run structural simulations with a few million degrees of freedom, and the largest commercial structural simulations have topped even 100 million degrees of freedom.

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

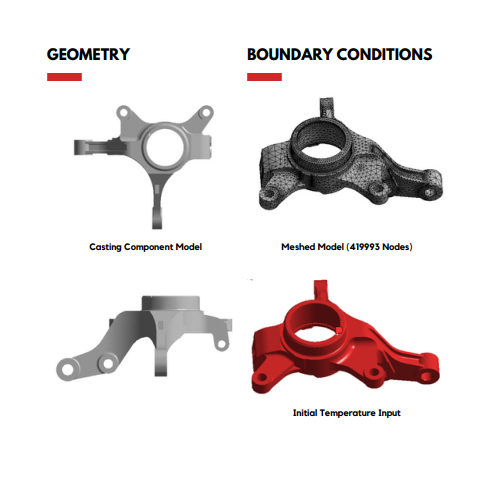

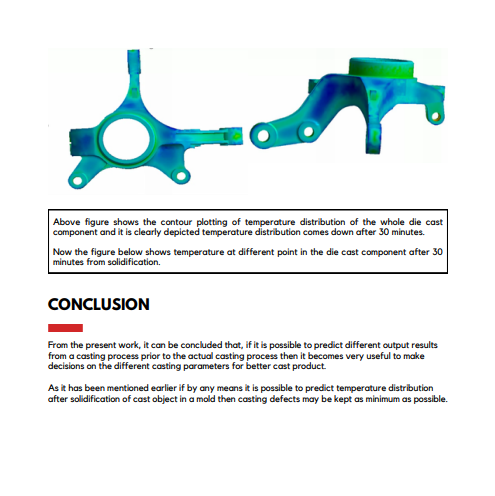

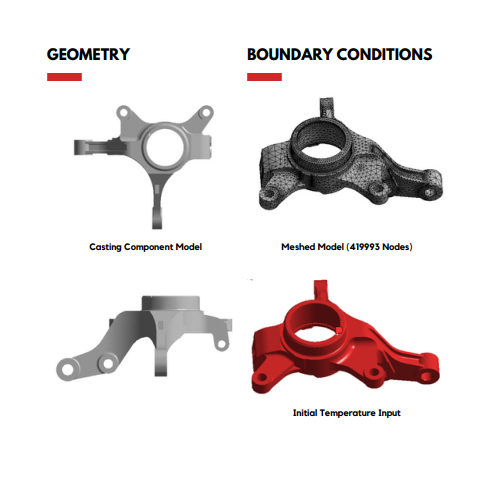

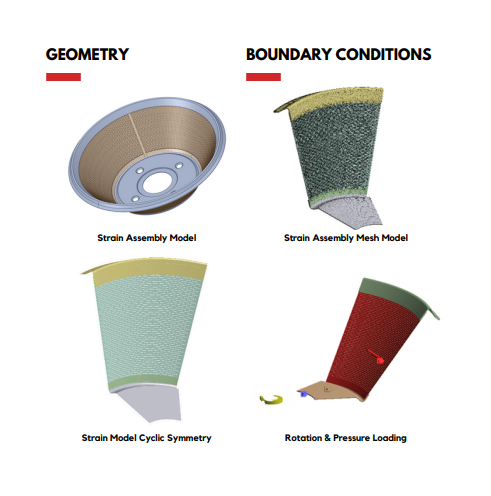

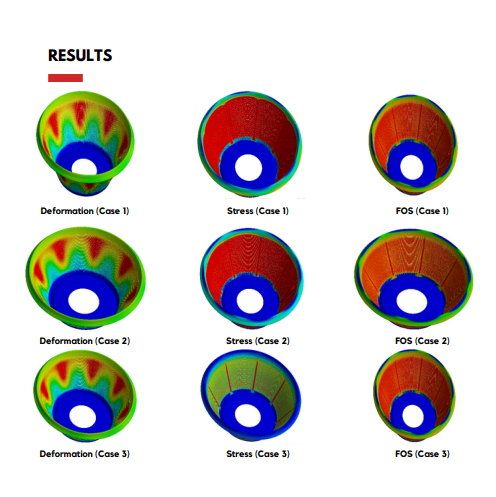

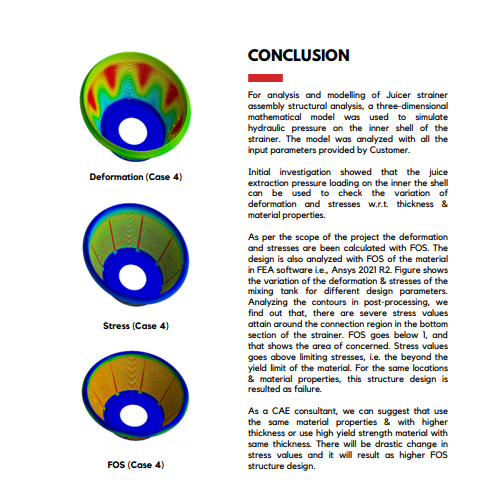

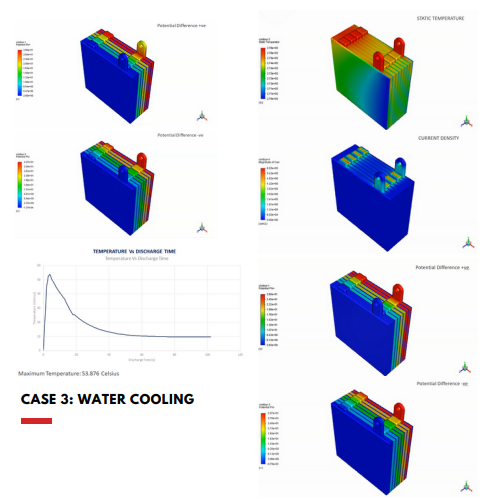

CaseStudies

Explore Case Studies

Qantur Technologies is a pioneer engineering simulations company based in Gurgaon –India. We provides expert Computer Aided Engineering – CAE consulting services for engineering / product design analysis by modeling & simulation.

Download Case Study

Transform Ideas into Reality—Explore Our Simulation Solutions Today!

Partner with Us to Revolutionize Engineering Excellence!

Testimonials

Customer Testimonials

Bengal Industries Pvt. Ltd

The ANSYS Mechanical training conducted by Qantur Technologies was highly informative and helped our engineers resolve critical challenges in contact modeling, meshing, and fatigue analysis. The sessions were well-coordinated, delivered on schedule, and supported with patient guidance by the trainer and account manager. We truly value Qantur’s expertise, professionalism, and post-sales support.

Bengal Industries Pvt. Ltd

Bliss Anand Pvt. Ltd.

During our evaluation of CFD solutions, Qantur Technologies stood out for their technical expertise, reliability, and customer-focused approach. Their consulting projects achieved 98% accuracy compared to experimental values, instilling strong confidence in their capabilities. Based on this experience, we selected them as our preferred partner for ANSYS software, consulting, training, and support. We highly recommend their services to organizations with simulation requirements.

Bliss Anand Pvt. Ltd.

CUET, Department of Mechanical Engineering

We experienced significant value from Qantur Technologies’ expertise in ANSYS solutions, particularly in FEA and CFD consulting. Their skilled engineers provided insightful training on geometry, meshing, and modeling, which enhanced our students’ and faculty’s analytical skills. With exceptional support and patience from their trainers, we are pleased to recommend Qantur Technologies for ANSYS implementation, training, and advanced simulation services.

CUET, Department of Mechanical Engineering

Entecnia Consulting Pvt. Ltd.

Our collaboration with Qantur Technologies for ANSYS implementation and consulting has been outstanding. Their commitment, technical expertise, and timely support in FEA and CFD have added significant value to our engineering and R&D teams. The exclusive 15-day training session further enhanced our team’s analytical skills, and we truly appreciate their professionalism and ownership in managing the entire process seamlessly. We highly recommend Qantur Technologies for advanced CAE solutions.

Entecnia Consulting Pvt. Ltd.

Flovel Energy Pvt. Ltd.

Our experience with Qantur Technologies in implementing ANSYS HPC and CFD solutions has been remarkable. Their skilled engineers conducted in-depth training for our R&D team, equipping us with advanced methods to simulate hydro turbines and enhance component performance. Their reliable support, technical expertise, and resource assistance make them a trusted partner for ANSYS software, consulting, and training. We highly recommend Qantur Technologies for any ANSYS-related services.

Flovel Energy Pvt. Ltd.

Flovel Energy Pvt. Ltd.

We truly value the ANSYS SpaceClaim training conducted by Qantur Technologies at our R&D center. The course was tailored to our requirements, highly informative, and supported by hands-on workshops that enhanced our team’s modeling skills. Their application engineer was proactive, helpful, and ensured customization aligned with our needs. We look forward to engaging Qantur Technologies again for future application-based trainings.

Flovel Energy Pvt. Ltd.

IoTechWorld Avigation Pvt. Ltd.

At IoTechWorld, we develop advanced drones for agriculture, survey, and surveillance, and ANSYS Mechanical & CFD have been instrumental in optimizing our designs. Qantur Technologies supported us with the right resources, training, and technical expertise to address complex FEA & CFD challenges. Their team’s commitment and knowledge have empowered us to innovate faster and more effectively. We highly recommend Qantur Technologies for ANSYS implementation, consulting, and support.

IoTechWorld Avigation Pvt. Ltd.

Karman Drones Pvt. Ltd.

Our collaboration with Qantur Technologies for At Karman Drones, innovation drives our mission in AI-powered autonomous drones. Qantur Technologies has been a key partner in implementing ANSYS software, providing outstanding FEA & CFD expertise, consulting, and hands-on training. Their engineers have empowered our team with advanced simulation knowledge, improving design validation, performance optimization, and overall efficiency. We highly recommend Qantur Technologies for their exceptional support and technical proficiency.

Karman Drones Pvt. Ltd.

Mittal Electronics

At Mittal Electronics, innovation and R&D are at the heart of our product development. Partnering with Qantur Technologies for ANSYS FEA & CFD has been transformative—helping us accelerate design validation, optimize performance, and tackle complex engineering challenges with confidence. Their expert training, consulting, and quick response have greatly strengthened our engineering capabilities. We look forward to continued collaboration with Qantur Technologies.

Mittal Electronics

MV Electrosystems Pvt. Ltd.

At MV Electrosystems, innovation in rail transportation demands precision and reliability. Partnering with Qantur Technologies for ANSYS ICEPAK & Mechanical has significantly enhanced our ability to optimize product design, improve efficiency, and accelerate development. Their expert training, technical guidance, and hands-on support in FEA & CFD not only strengthened our engineering skills but also deepened our understanding of core physics. We truly value this collaboration and highly recommend Qantur Technologies for simulation-driven innovation.

MV Electrosystems Pvt. Ltd.

Nicotra India Pvt. Ltd.

At Nicotra India, precision in fan design is critical. Qantur Technologies has been a valuable partner, providing quick and responsive CFD support—both onsite and online—that helped us validate designs and solve complex meshing and model setup challenges. Their extensive training sessions empowered our R&D team with practical simulation expertise, strengthening our analytical and design capabilities. We are pleased with their services and highly recommend them for ANSYS implementation and technical support.

Nicotra India Pvt. Ltd.

NTF (India) Pvt. Ltd.

At NTF India, we rely on advanced engineering solutions to deliver world-class automotive components. Qantur Technologies has been a trusted partner, supporting us with ANSYS implementation and in-depth FEA analysis for our key projects. Their professionalism, technical expertise, and ability to deliver under challenging conditions have consistently exceeded our expectations. We highly value their commitment and look forward to continued collaboration on future product development initiatives.

NTF (India) Pvt. Ltd.

Onassis Auto Limited

At Onassis Auto, precision and reliability are at the core of our automotive components. With Qantur Technologies’ guidance in Ansys Mechanical, we have successfully enhanced our engineering capabilities, optimized transmission components, and improved efficiency. Their hands-on training, prompt support, and expertise in FEA have greatly empowered our R&D team. We are pleased to recommend Qantur Technologies for their outstanding technical services and commitment.

Onassis Auto Limited

P2P Analysis & Solutions

At P2P Analysis & Solutions, innovation is our core, and Qantur Technologies has been an invaluable partner in this journey. Their technical excellence in Ansys Mechanical and LS-DYNA, coupled with meticulous training and proactive support, has empowered our team to solve complex challenges with confidence. Their professionalism, collaborative approach, and customer-centric commitment make them a trusted long-term partner. We strongly recommend Qantur Technologies for any Ansys-related solutions and services.

P2P Analysis & Solutions

S&O Marintime

S&O Marintime