Industries

Automotive

Transportation & Mobility

Simulating the Future of Transportation and Mobility

Exponentially innovate to deliver the transportation and mobility experiences of the future with the next generation of simulation and engineering tools.

Cut costs & innovate

quickly with simulation

The automotive industry is a cornerstone of modern innovation, driving advancements in vehicle efficiency, safety, and sustainability. This sector encompasses the design, production, and operation of vehicles, requiring precise engineering and cutting-edge technology. Ansys software plays a vital role in this industry, offering solutions such as Ansys Mechanical for structural and thermal analysis, Ansys Fluent for fluid dynamics and aerodynamics, Ansys Maxwell for electromagnetics in electric motors, Ansys Icepak for thermal management of electronic components, Ansys LS-DYNA for crash and impact simulations, and other specialized tools. These powerful simulation solutions enable the development of innovative, reliable, and sustainable vehicles, meeting the highest standards of performance and safety in the automotive industry.

- Electric Vehicles

- Vehicle Engineering

- Simulation Solutions

- ADAS & Autonomous Vehicles

Cars & Trucks Light

Ansys delivers precise simulation solutions designed for the complex engineering demands of vehicle technology.

Its comprehensive tools enable end-to-end simulation of vehicle systems, from structure to software.

Capabilities include structural, crash, fluids, thermal, electromagnetics, electronics, and semiconductor analysis.

Structural and fatigue analysis to assess the durability, strength, and safety of critical components.

Crash and impact simulations to enhance passenger safety during accidents.

Aerodynamic testing to refine vehicle shape, reduce drag, and improve fuel efficiency.

Thermal management of engines and braking systems for consistent performance.

NVH (Noise, Vibration, and Harshness) analysis to optimize passenger comfort by minimizing noise and vibration.

Component-Level Capabilities

Ansys offers advanced component-level simulation solutions that empower automotive engineers to optimize individual parts with precision.

These tools support detailed analysis across structural, thermal, fluid, and electronic domains, ensuring reliability, safety, and performance at every stage of development.

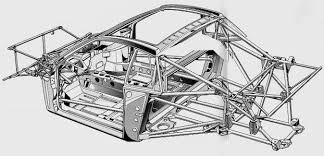

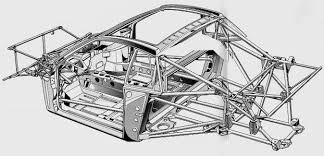

Chassis & Frame

- Perform structural analysis on chassis to withstand operational stresses, vibrations, and impacts.

- Simulate thermal effects on the frame to assess performance under varying temperature conditions.

Engine Block

- Analyze thermal stresses and heat transfer to maintain engine reliability under high temperatures.

- Conduct structural and vibrational simulations to evaluate the engine block's strength and resistance to fatigue under operating conditions.

Brake System

- Simulate heat dissipation during braking to preserve braking efficiency and safety.

- Evaluate wear characteristics to extend the service life and reliability of the brake components.

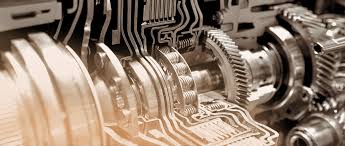

Transmission System

- Perform structural analysis under varying load conditions to ensure smooth operation and power delivery.

- Evaluate fluid dynamics of lubrication to ensure all moving components are lubricated adequately.

Fuel Injection System

- Conduct fluid dynamics simulation to optimize fuel atomization and air-fuel mixing to enhance combustion efficiency.

- Assess structural durability and reliability under high-pressure conditions to prevent failures.

Relevant Ansys Software

Assists in the analysis and design of composite materials, widely used for lightweighting in vehicles.

Heavy Trucks

ANSYS provides in-depth simulation solutions tailored for the rigorous demands of heavy truck engineering.Its comprehensive tools enable analysis from structural robustness and thermal management to aerodynamic efficiency, ensuring optimal performance and reliability.

Structural analysis for load-bearing components to ensure strength and durability in heavy-duty operations.

Aerodynamic optimization to minimize drag, improving fuel efficiency and reducing operational costs.

Thermal simulation for engine and cooling systems to ensure reliable performance in long-distance, heavy-load conditions.

Vibration and fatigue analysis to increase component longevity and reduce maintenance needs.

Exhaust and emissions testing to meet regulatory standards and optimize environmental performance.

Component-Level Capabilities

Engine

- Perform structural and vibrational analysis on engine components to ensure load-carrying capacity and durability.

- Ensure cooling system reliability to maintain engine performance during long-haul operations.

Axle and Drivetrain

- Analyze load-bearing capacity to withstand high-stress conditions, particularly on rough terrains

- Simulate fatigue characteristics under cyclic loading to ensure long service life. .

Brake and Suspension Systems

- Evaluate the thermal performance of brake system components for reliable and effective performance.

- Simulate the kinematic motion of suspension system components to ensure the desired results.

Transmission System

- Test the structural strength of gears and other components under high-load conditions to ensure smooth performance.

- Analyze noise and vibration levels in the gear train to improve component longevity.

Relevant Ansys Software

Motorcycles

Structural analysis to balance durability with the agility required for handling and performance.

Vibration testing to reduce the risk of fatigue and enhance rider comfort on rides.

Aerodynamic optimization to reduce drag and increase fuel efficiency for extended range.

Acoustic simulations to ensure compliance with noise regulations while enhancing rider comfort.

Thermal analysis for engine and exhaust systems to prevent overheating during operation.

Component-Level Capabilities

Frame and Chassis

- Evaluate structural integrity to withstand static loads and impacts, ensuring rider safety.

- Conduct vibration and fatigue analysis to assess the performance and durability under cyclic loading and operational conditions.

Suspension

- Perform rigid body motion simulations to assess the behaviour of suspension system components across various road surfaces.

- Conduct fatigue analysis to assess the durability of suspension components under repetitive loading, maximizing system lifespan.

Engine Cooling System

- Use thermal simulations to manage heat dissipation and prevent engine overheating during extended high-performance runs.

- Optimize cooling efficiency through fluid dynamics simulations to ensure consistent engine performance and temperature regulation under varying load conditions.

Transmission System

- Perform wear analysis on gears to evaluate durability, ensuring smooth shifting and reliable performance.

- Simulate lubrication flow using computational fluid dynamics (CFD) to ensure adequate distribution of lubricant to all rotating components.

Relevant Ansys Software

Aids in the design and analysis of composite materials used for lightweight body panels, frames, and protective covers.

Electric Vehicle

Thermal simulations for battery systems to prevent overheating and maintain optimal operating temperatures.

Electric motor design and optimization for improved efficiency, torque, and power.

Aerodynamic testing to reduce drag, improving driving range and battery life.

EMI/EMC testing to ensure electromagnetic compatibility of sensors and prevent interference with other vehicle systems.

Structural analysis to optimize weight while enhancing crashworthiness and safety.

Component-Level Capabilities

Battery Pack

- Manage heat dissipation from the battery to prevent thermal runaway and extend service life.

- Test structural strength to ensure safety and reliability in the event of a collision or impact.

Electric Motor

- Simulate electromagnetic interactions to optimize torque generation and power output.

- Analyze thermal behaviour to prevent overheating during peak motor performance.

Power Electronics

- Evaluate embedded software performance to ensure optimal operation of power electronics under varying load conditions.

- Conduct EMI/EMC analysis to ensure smooth operation without interference from other electronics.

Cell Analysis

- Simulate the electrochemistry of cells and assess the voltage and current density.

- Analyze the thermal runaway of cells, to ensure a safer design of the battery.

Relevant Ansys Software

Finite element analysis for structural performance

Analyzes composite materials for lightweight body panels, battery enclosures, and structural parts.

Predicts residual stresses and deformations during composite curing processes.

Electric Motor Simulation

Thermal analysis to manage heat generation and dissipation, preventing overheating.

Electromagnetic simulations to optimize motor efficiency, torque production, and overall performance.

Structural integrity testing to ensure motor durability under dynamic and operational stresses.

Vibration analysis to reduce noise, improve stability, and enhance overall motor reliability.

Component-Level Capabilities

Rotor and Stator Design

- Simulate electromagnetic interactions to enhance motor efficiency and optimize torque.

- Analyze mechanical stresses and structural integrity to ensure long-lasting motor performance.

Cooling System

- Perform thermal analysis to prevent overheating and maintain optimal operation.

- Use fluid dynamics simulations to analyze the flow of coolant and heat transfer, in liquid-cooled high-performance electric motors.

Bearing System

- Perform wear analysis to ensure long operational life of components.

- Simulate vibration and fatigue to assess the behaviour of components and ensure reliability.

Relevant Ansys Software

Finite element analysis for structural performance

Simulates power, electrical, and control systems to optimize the interaction between sensors, actuators, and controllers.

Agriculture, Construction, and

Mining Vehicles

Structural durability testing for components under extreme loads and harsh environments.

Thermal analysis for engines and hydraulic systems to ensure reliability in high-stress conditions.

Vibration and shock testing of components to enhance reliability and reduce maintenance requirements on uneven terrains.

Noise, vibration, and harshness (NVH) analysis to meet noise regulations and improve operator comfort.

Component-Level Capabilities

Hydraulic Systems

- Analyze fluid pressure and flow characteristics in hydraulic systems to ensure effective performance.

- Perform structural analysis on components to withstand the fluid pressure loads and prevent leaks.

Cabin Structure

- Test structural integrity to ensure operator safety, especially in the case of rollovers.

- Evaluate noise and vibration factors to enhance operator comfort.

Undercarriage and Tracks

- Simulate wear resistance for longevity in abrasive environments.

- Perform rigid body motion analysis to optimize the movement and interaction of undercarriage components, ensuring smooth motion across rough terrains.

Relevant Ansys Software

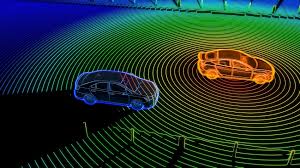

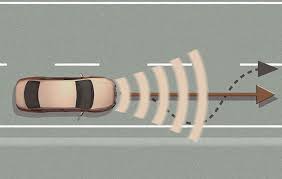

Autonomous Vehicle Systems and

Advanced Driver Assistance Systems

Simulate electromagnetics of sensors and radar systems to validate object detection and perception capabilities.

Perform electromagnetic analysis to ensure sensor signal integrity and minimize interference.

Implement SIL (Software-in-the-Loop) and HIL (Hardware-in-the-Loop) testing for accurate control system performance and validation.

Test virtually, the performance and functionality of various sensors in real-world driving conditions in different scenarios.

Component-Level Capabilities

Lidar and Radar Sensors

- Simulate sensor detection capabilities to ensure accurate and reliable object identification across different environmental conditions.

- Perform signal integrity and electromagnetic interference analysis to mitigate external disruptions and enhance detection reliability.

Camera Systems

- Simulate all components of a camera, such as the lens system, imager and pre-processor.

- Evaluate the influence of environmental factors like rain, fog, or glare on image quality and recognition accuracy.

ECU (Electronic Control Unit)

- Validate control algorithms through software-in-the-loop (SIL) and hardware-in-the-loop (HIL) testing for optimal vehicle performance.

- Perform electromagnetic analysis to test the ECU’s susceptibility to interference, ensuring it functions properly alongside other electrical systems within the vehicle.

Lane Keeping Assist

- Simulate real-world driving conditions to ensure accurate lane detection and control.

- Test control algorithms for smooth and responsive lane-keeping in diverse road scenarios.

Adaptive Cruise Control

- Evaluate system responsiveness to maintain safe following distances in dynamic traffic conditions.

- Test integration with vehicle control systems for smooth acceleration, deceleration, and braking.

Relevant Ansys Software

A platform for testing and validating autonomous driving algorithms, including sensor fusion, perception systems, and decision-making processes in simulated environments.

A virtual simulation platform that tests and validates autonomous vehicle systems, including sensor performance (radar, LiDAR, cameras), object detection, and ADAS features, ensuring robust operation in real-world scenarios.

Simulates power integrity, signal integrity, and electromagnetic interference for electronic systems in autonomous vehicles, ensuring reliable sensor and communication performance.

Ansys Simplorer

Simulates power, electrical, and control systems to optimize the interaction between sensors, actuators, and controllers.

Public Transportation Vehicles

Crash and impact simulations on structural components to improve passenger safety and minimize injuries.

Structural analysis for resilience under passenger and cargo loads.

Fluid dynamics and heat transfer analysis on HVAC system to enhance passenger convenience.

Noise and vibration analysis to minimize operational noise and improve comfort.

Aerodynamics simulation to reduce drag and improve energy efficiency.

Component-Level Capabilities

Chassis and Frame

- Evaluate structural integrity to maintain vehicle performance under substantial passenger and cargo loads.

- Simulate impacts and collisions on the chassis to ensure the safety of passengers.

Brake System

- Simulate heat dissipation during heavy braking to preserve braking efficiency and safety.

- Evaluate wear characteristics to extend the service life and reliability of the brake components.

HVAC System

- Perform thermal and fluid flow analysis to ensure consistent air distribution and conditioning for passenger comfort.

- Analyze thermal expansion/contraction and stresses on system components due to heating or cooling.

Relevant Ansys Software

Ansys VRXPERIENCE

Offers virtual reality simulations to evaluate vehicle ergonomics, user interfaces, and passenger comfort before physical prototypes are built.

interested in our Product or Solution

Still have a Question?

FAQ

How can ANSYS improve the performance of my automotive designs?

ANSYS allows for detailed simulation and analysis, enabling optimization of factors like aerodynamics, structural integrity, and thermal management. This leads to better performing and more efficient vehicles.

Can ANSYS help reduce the time and cost of automotive development?

Yes, by providing accurate virtual testing, ANSYS reduces the need for physical prototypes and testing cycles. This leads to faster development times and significant cost savings.

What types of automotive simulations can ANSYS perform?

ANSYS can handle a wide range of simulations, including crash analysis, fluid dynamics for aerodynamics, thermal analysis for engine cooling, and NVH analysis for noise reduction.

Is ANSYS compatible with my existing CAD software?

ANSYS is designed to integrate with most standard CAD software, ensuring a smooth workflow. We support common file formats for easy data transfer and interoperability

Transform Ideas into Reality—Explore Our Simulation Solutions Today!

Partner with Us to Revolutionize Engineering Excellence!

Testimonials

Customer Testimonials

Bengal Industries Pvt. Ltd

The ANSYS Mechanical training conducted by Qantur Technologies was highly informative and helped our engineers resolve critical challenges in contact modeling, meshing, and fatigue analysis. The sessions were well-coordinated, delivered on schedule, and supported with patient guidance by the trainer and account manager. We truly value Qantur’s expertise, professionalism, and post-sales support.

Bengal Industries Pvt. Ltd

Bliss Anand Pvt. Ltd.

During our evaluation of CFD solutions, Qantur Technologies stood out for their technical expertise, reliability, and customer-focused approach. Their consulting projects achieved 98% accuracy compared to experimental values, instilling strong confidence in their capabilities. Based on this experience, we selected them as our preferred partner for ANSYS software, consulting, training, and support. We highly recommend their services to organizations with simulation requirements.

Bliss Anand Pvt. Ltd.

CUET, Department of Mechanical Engineering

We experienced significant value from Qantur Technologies’ expertise in ANSYS solutions, particularly in FEA and CFD consulting. Their skilled engineers provided insightful training on geometry, meshing, and modeling, which enhanced our students’ and faculty’s analytical skills. With exceptional support and patience from their trainers, we are pleased to recommend Qantur Technologies for ANSYS implementation, training, and advanced simulation services.

CUET, Department of Mechanical Engineering

Entecnia Consulting Pvt. Ltd.

Our collaboration with Qantur Technologies for ANSYS implementation and consulting has been outstanding. Their commitment, technical expertise, and timely support in FEA and CFD have added significant value to our engineering and R&D teams. The exclusive 15-day training session further enhanced our team’s analytical skills, and we truly appreciate their professionalism and ownership in managing the entire process seamlessly. We highly recommend Qantur Technologies for advanced CAE solutions.

Entecnia Consulting Pvt. Ltd.

Flovel Energy Pvt. Ltd.

Our experience with Qantur Technologies in implementing ANSYS HPC and CFD solutions has been remarkable. Their skilled engineers conducted in-depth training for our R&D team, equipping us with advanced methods to simulate hydro turbines and enhance component performance. Their reliable support, technical expertise, and resource assistance make them a trusted partner for ANSYS software, consulting, and training. We highly recommend Qantur Technologies for any ANSYS-related services.

Flovel Energy Pvt. Ltd.

Flovel Energy Pvt. Ltd.

We truly value the ANSYS SpaceClaim training conducted by Qantur Technologies at our R&D center. The course was tailored to our requirements, highly informative, and supported by hands-on workshops that enhanced our team’s modeling skills. Their application engineer was proactive, helpful, and ensured customization aligned with our needs. We look forward to engaging Qantur Technologies again for future application-based trainings.

Flovel Energy Pvt. Ltd.

IoTechWorld Avigation Pvt. Ltd.

At IoTechWorld, we develop advanced drones for agriculture, survey, and surveillance, and ANSYS Mechanical & CFD have been instrumental in optimizing our designs. Qantur Technologies supported us with the right resources, training, and technical expertise to address complex FEA & CFD challenges. Their team’s commitment and knowledge have empowered us to innovate faster and more effectively. We highly recommend Qantur Technologies for ANSYS implementation, consulting, and support.

IoTechWorld Avigation Pvt. Ltd.

Karman Drones Pvt. Ltd.

Our collaboration with Qantur Technologies for At Karman Drones, innovation drives our mission in AI-powered autonomous drones. Qantur Technologies has been a key partner in implementing ANSYS software, providing outstanding FEA & CFD expertise, consulting, and hands-on training. Their engineers have empowered our team with advanced simulation knowledge, improving design validation, performance optimization, and overall efficiency. We highly recommend Qantur Technologies for their exceptional support and technical proficiency.

Karman Drones Pvt. Ltd.

Mittal Electronics

At Mittal Electronics, innovation and R&D are at the heart of our product development. Partnering with Qantur Technologies for ANSYS FEA & CFD has been transformative—helping us accelerate design validation, optimize performance, and tackle complex engineering challenges with confidence. Their expert training, consulting, and quick response have greatly strengthened our engineering capabilities. We look forward to continued collaboration with Qantur Technologies.

Mittal Electronics

MV Electrosystems Pvt. Ltd.

At MV Electrosystems, innovation in rail transportation demands precision and reliability. Partnering with Qantur Technologies for ANSYS ICEPAK & Mechanical has significantly enhanced our ability to optimize product design, improve efficiency, and accelerate development. Their expert training, technical guidance, and hands-on support in FEA & CFD not only strengthened our engineering skills but also deepened our understanding of core physics. We truly value this collaboration and highly recommend Qantur Technologies for simulation-driven innovation.

MV Electrosystems Pvt. Ltd.

Nicotra India Pvt. Ltd.

At Nicotra India, precision in fan design is critical. Qantur Technologies has been a valuable partner, providing quick and responsive CFD support—both onsite and online—that helped us validate designs and solve complex meshing and model setup challenges. Their extensive training sessions empowered our R&D team with practical simulation expertise, strengthening our analytical and design capabilities. We are pleased with their services and highly recommend them for ANSYS implementation and technical support.

Nicotra India Pvt. Ltd.

NTF (India) Pvt. Ltd.

At NTF India, we rely on advanced engineering solutions to deliver world-class automotive components. Qantur Technologies has been a trusted partner, supporting us with ANSYS implementation and in-depth FEA analysis for our key projects. Their professionalism, technical expertise, and ability to deliver under challenging conditions have consistently exceeded our expectations. We highly value their commitment and look forward to continued collaboration on future product development initiatives.

NTF (India) Pvt. Ltd.

Onassis Auto Limited

At Onassis Auto, precision and reliability are at the core of our automotive components. With Qantur Technologies’ guidance in Ansys Mechanical, we have successfully enhanced our engineering capabilities, optimized transmission components, and improved efficiency. Their hands-on training, prompt support, and expertise in FEA have greatly empowered our R&D team. We are pleased to recommend Qantur Technologies for their outstanding technical services and commitment.

Onassis Auto Limited

P2P Analysis & Solutions

At P2P Analysis & Solutions, innovation is our core, and Qantur Technologies has been an invaluable partner in this journey. Their technical excellence in Ansys Mechanical and LS-DYNA, coupled with meticulous training and proactive support, has empowered our team to solve complex challenges with confidence. Their professionalism, collaborative approach, and customer-centric commitment make them a trusted long-term partner. We strongly recommend Qantur Technologies for any Ansys-related solutions and services.

P2P Analysis & Solutions

S&O Marintime

S&O Marintime

Shubham Packaging

Shubham Packaging

Fill out the form below, And you will get Case Study on Email

Subscribe

Join our newsletter to stay up to date onfeatures and news release.

By subscribing you agree to with our privacy policy and provide content to receive updates from our company.