Industries

Energy

Simulating the Future of Transportation and Mobility

Exponentially innovate to deliver the transportation and mobility experiences of the future with the next generation of simulation and engineering tools.

Cut costs & innovate

quickly with simulation

The energy industry is essential for driving sustainable development and meeting global power demands. It involves designing and optimizing systems for energy generation, storage, and transmission while prioritizing efficiency, safety, and environmental responsibility. Ansys provides a vast range of simulation tools to address these needs, including Ansys Mechanical for structural analysis, Ansys Fluent for fluid dynamics, electrochemical reactions, and heat transfer, Ansys CFX for turbomachinery applications, Ansys Maxwell for electromagnetic simulations, and Ansys Chemkin-Pro for combustion reaction kinetics. These tools enable engineers to innovate, analyze, and enhance energy systems for superior performance and sustainability.

- Electric Vehicles

- Vehicle Engineering

- Simulation Solutions

- Simulation Solutions

- ADAS & Autonomous Vehicles

Battery

ANSYS Battery offers advanced simulation tools for designing and optimizing battery cells, modules, and packs across performance, safety, and lifespan criteria. It enables multiphysics analysis including thermal, electrical, and structural behavior for electric vehicle and energy storage applications.

Thermal management and runaway simulations to prevent overheating and improve safety.

Structural analysis to ensure the durability and safety of battery components.

Electrochemistry simulations to predict the operation lifetime of the battery.

Vibration analysis to reduce the risk of fatigue, and extend battery life.

Component-Level Capabilities

ANSYS Battery Component-Level Capabilities provide detailed simulations of individual battery cells and components, focusing on thermal management, electrochemical performance, and structural integrity. These tools help enhance reliability, safety, and efficiency in battery design.

Battery Cells

- Simulate and optimize thermal performance for efficient heat dissipation.

- Analyze structural strength to absorb shock loads and enhance long-term durability.

Battery Packs

- Test thermal distribution for uniform temperature control across packs.

- Evaluate structural performance to ensure safety and reliability under operational stresses, including impacts.

Cooling Systems

- Simulate fluid dynamics to optimize heat removal and maintain safe temperature ranges.

- Assess the structural durability of cooling components under operational loads.

Control Electronics

- Evaluate electromagnetic interference to ensure reliable and efficient operation.

- Perform thermal analysis to protect sensitive electronic components.

Relevant Ansys Software

ANSYS Battery leverages software like ANSYS Fluent, Mechanical, and Twin Builder to simulate electrochemical, thermal, and structural behaviors. This integration supports accurate, multi-physics analysis for efficient and safe battery system development.

Material selection for performance, cost, and sustainability.

Turbines

ANSYS Turbines is a simulation solution designed for analyzing and optimizing turbine performance across various industries. It enables detailed modeling of fluid flow, heat transfer, and structural mechanics within turbine components.

Thermal management to improve efficiency and prevent overheating of turbine systems.

Structural analysis to ensure turbine components withstand dynamic loads and environmental stresses.

Vibration analysis to reduce noise and improve operational stability.

Performance testing to evaluate turbine behaviour in various environmental conditions.

Aerodynamic simulations to optimize blade design and enhance efficiency.

Component-Level Capabilities

ANSYS Turbines’ component-level capabilities allow precise simulation of individual turbine parts like blades, vanes, and rotors. These tools support detailed analysis of fluid dynamics, thermal effects, and structural integrity for optimized performance.

Wind Turbines

- Simulate aerodynamic performance for improved energy conversion efficiency.

- Analyze the structural integrity of turbine components to withstand environmental loads.

Gas Turbines

- Test thermal performance and optimize combustion for reduced fuel consumption and emissions.

- Select the best-suited materials for high-temperature durability and system reliability.

Hydro Turbines

- Simulate fluid dynamics for optimal energy conversion from water flow.

- Analyze structural components for long-term reliability under dynamic fluid forces.

Steam Turbines

- Simulate thermal performance to assess optimal heat transfer.

- Evaluate vibration effects to enhance operational stability and reduce noise.

Blades and Rotors

- Simulate aerodynamic forces to optimize blade and rotor design for maximum performance.

- Perform structural analysis to assess stress, deformation, and fatigue under operational loading conditions.

Relevant Ansys Software

Relevant ANSYS software for turbine simulation includes ANSYS CFX, Fluent, and Mechanical, enabling high-fidelity fluid, thermal, and structural analysis. These tools work together to deliver accurate, multi-physics insights for turbine design and optimization.

Advanced CFD for turbomachinery and rotating equipment.

Aerodynamics design and analysis for turbomachinery.

Specialized for turbomachinery design, allowing ultra-fast simulations for preliminary designs to evaluate flow paths and performance.

Ansys Composite PrepPost

Provides tools for modelling and analyzing composite materials used in turbine blades, ensuring proper layer configuration for optimal strength and performance.

Focuses on the design and analysis of turbine blades, optimizing aerodynamic performance to reduce losses.

Simulates electromagnetic fields for designing and optimizing generators in wind and hydro turbines.

Ansys Composite Cure Simulation

Simulates the curing process of composite materials, predicting residual stresses and deformations in turbine blades during manufacturing.

Solar Equipment

ANSYS Solar Equipment solutions provide advanced simulation tools for designing and optimizing solar energy systems. They enable analysis of thermal performance, structural integrity, and environmental impact to enhance efficiency and durability.

Thermal simulations to optimize heat dissipation and system performance.

Structural analysis to ensure the durability and safety of solar panels and associated components.

Electromagnetic and electrical simulations to improve the efficiency of solar energy conversion.

Select the best materials to improve efficiency and performance.

Component-Level Capabilities

ANSYS Solar Equipment component-level capabilities enable detailed simulation of parts like solar panels, inverters, and mounting structures. These tools support thermal, electrical, and structural analysis to ensure optimal performance and reliability.

Solar Panels

- Simulate structural integrity to ensure long-term durability against environmental factors.

- Analyze thermal management to prevent overheating and enhance energy efficiency.

Photovoltaic Cells

- Test electrical performance for efficient energy conversion under various lighting conditions.

- Select optimal materials to enhance durability and maximize efficiency.

Mounting Systems

- Simulate the structural strength to ensure reliability in various environmental conditions, including strong winds.

- Analyze vibration effects to improve operational stability and reduce system wear

Inverters

- Evaluate electromagnetic performance for efficient DC-to-AC power conversion.

- Test thermal management to ensure optimal performance and prevent overheating.

Solar Trackers

- Simulate mechanical behaviour for accurate positioning and maximizing sunlight exposure.

- Analyze the influence of vibration on the precision and fatigue characteristics of the tracker.

Relevant Ansys Software

Relevant ANSYS software for solar equipment includes ANSYS Fluent, Mechanical, and Twin Builder, enabling multi-physics simulation of thermal, structural, and electrical behavior. These tools help optimize design, efficiency, and longevity of solar systems.

Photonic design software for multiphysics-driven innovation.

Material selection for performance, cost, and sustainability.

Thermal management simulation for electronics cooling solutions.

Models composite materials used in lightweight solar panel frames and supports to optimize strength and reduce weight.

Grid and Power Distribution

ANSYS Grid and Power Distribution solutions support the design and analysis of electrical grids and power delivery systems. They enable simulation of electromagnetic, thermal, and system-level behavior to ensure efficiency, safety, and reliability.

Thermal management to prevent overheating and improve efficiency in power systems.

Structural analysis to ensure the durability and reliability of grid components.

Electromagnetic simulations for efficient power transmission across the grid.

Vibration analysis to minimize noise and enhance system stability.

Component-Level Capabilities

ANSYS Grid and Power Distribution component-level capabilities allow detailed analysis of transformers, switchgear, cables, and circuit breakers. These tools simulate electromagnetic, thermal, and mechanical performance for optimized design and operation.

Transformers

- Simulate electromagnetic performance to ensure efficient energy conversion.

- Test thermal management to prevent overheating and optimize operational efficiency.

Cables and Busbars

- Evaluate structural integrity to ensure reliable power transmission.

- Perform thermal analysis to optimize heat dissipation and prevent overheating during high-current conditions.

Switchgear

- Simulate electromagnetic interactions to ensure safe and efficient switching operations.

- Perform structural analysis to verify reliability under operational conditions.

Relevant Ansys Software

Relevant ANSYS software for grid and power distribution includes ANSYS Maxwell, Mechanical, and Circuit Designer. These tools enable comprehensive simulation of electromagnetic, thermal, and electrical system behavior for reliable and efficient power infrastructure.

Electromagnetic field simulation for motors and actuators.

Ansys Composite PrepPost

Models composite materials used in lightweight, durable power distribution structures such as poles and enclosures.

Simulates charge accumulation and electrostatic effects in high-voltage equipment, ensuring safety and performance.

Nuclear Reactor Plants

ANSYS solutions for Nuclear Reactor Plants provide high-fidelity simulation tools for analyzing reactor core behavior, thermal hydraulics, and structural integrity. They support safe, efficient, and regulatory-compliant nuclear plant design and operation.

Thermal simulations to manage heat generation and dissipation in reactor cores.

Structural analysis to ensure the durability of reactor cores and shielding materials.

Performance testing under various operating conditions to verify reactor stability and safety.

Material optimization to enhance reactor efficiency and reduce operational costs.

Component-Level Capabilities

ANSYS Nuclear Reactor Plants component-level capabilities enable detailed simulation of reactor components such as fuel rods, pressure vessels, and control systems. These tools optimize thermal, structural, and radiation behavior to ensure safety and efficiency.

Reactor Cores

- Simulate heat generation and thermal dissipation to ensure optimal reactor performance.

- Analyze structural integrity to prevent failure and ensure safe operation.

Control Rods

- Select the most suitable materials for long-term durability and performance under nuclear reaction conditions.

- Perform structural and thermal analysis to assess the response of control rods to extreme reactor environments.

Shielding Structures

- Perform structural and thermal analysis to evaluate the integrity and durability of shielding materials under extreme operational conditions.

- Select the best materials for resilience to radiation and structural integrity over time.

Cooling Systems

- Simulate fluid dynamics for efficient cooling of steam in the cooling towers.

- Assess structural strength of cooling towers under mechanical stresses to ensure long-term durability and safety.

Containment Structures

- Perform structural simulations to assess the integrity of containment structures under extreme conditions, including earthquakes.

- Select and optimize materials best suited to offer the highest levels of protection and durability.

Relevant Ansys Software

Relevant ANSYS software for nuclear reactor plants includes ANSYS Fluent, Mechanical, and Shielding. These tools facilitate comprehensive simulations of fluid flow, structural integrity, and radiation shielding to ensure reliable and safe reactor performance.

CFD software for flow, heat, and reactions.

Fatigue life prediction for durability engineering.

Ansys Composite PrepPost

Models composite materials used in reactor components, optimizing for strength, lightweighting, and radiation shielding.

Build, validate, and deploy digital twin models.

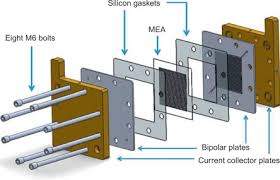

Hydrogen Fuel Cell

ANSYS Hydrogen Fuel Cell solutions provide advanced simulation tools to optimize the design and performance of hydrogen fuel cells. They enable detailed analysis of fluid dynamics, thermal behavior, and electrochemical processes for enhanced efficiency and durability.

Thermal management to optimize operating temperatures.

Structural analysis to ensure the durability and safety of fuel cell components.

Electrochemical reaction simulation to assess the effectiveness of the fuel cell.

Fluid dynamics for efficient flow of hydrogen and oxygen gases.

Optimal material selection to improve fuel cell efficiency and reduce cost.

Component-Level Capabilities

ANSYS Hydrogen Fuel Cell component-level capabilities enable detailed simulation of fuel cell components such as membranes, electrodes, and catalysts. These tools optimize electrochemical, thermal, and fluidic performance for improved efficiency and lifespan.

Membrane Electrode Assembly (MEA)

- Simulate fluid dynamics for efficient hydrogen reaction.

- Select appropriate materials to enhance performance and durability.

Bipolar Plates

- Test thermal management for efficient heat transfer.

- Simulate the flow of water produced during the reaction.

Catalysts

- Simulate chemical reactions for optimal catalyst performance.

- Choose the best materials to improve catalyst efficiency and lifespan.

Cooling Systems

- Simulate fluid dynamics to optimize heat dissipation and enhance performance.

- Analyze structural components for reliable performance under operational stresses.

Relevant Ansys Software

Relevant ANSYS software for hydrogen fuel cells includes ANSYS Fluent, Mechanical, and Electromagnetics. These tools enable comprehensive simulations of fluid dynamics, thermal management, and electrochemical processes to optimize fuel cell performance and design.

Ansys Composite PrepPost

Models composite materials used in lightweight fuel cell stacks and enclosures to enhance strength and reduce weight.

Wind Turbines

ANSYS Wind Turbine solutions offer advanced simulation tools for optimizing the design and performance of wind turbine systems. They enable detailed analysis of aerodynamics, structural integrity, and fatigue to enhance efficiency and durability in varying environmental conditions.

Thermal simulations to prevent overheating and improve system efficiency in varying environmental conditions.

Structural analysis to guarantee blade durability and reliability under dynamic loads, including wind gusts and operational stresses.

Aerodynamic simulations to optimize blade design and performance, ensuring maximum energy capture.

Vibration analysis to minimize noise and enhance stability, reducing fatigue and maintaining operational integrity.

Component-Level Capabilities

ANSYS Wind Turbines component-level capabilities enable detailed simulation of individual turbine components like blades, drivetrains, and gearboxes. These tools analyze aerodynamic, structural, and fatigue behaviors to optimize efficiency, durability, and reliability.

Blades

- Simulate aerodynamic performance for efficient energy conversion by optimizing its shape.

- Analyze structural strength to withstand wind loads, dynamic stresses, and fatigue over the blade’s lifecycle.

Towers

- Simulate load-bearing capacity for stability and safety of the wind turbine under wind-induced forces and seismic events.

- Analyze the effects of corrosion on tower materials to optimize design for enhanced longevity in harsh outdoor environments.

Gearboxes

- Simulate gear meshing and lubrication performance to optimize gearbox efficiency and reduce wear in the power transmission system.

- Evaluate the structural strength of gears and other components to ensure that they can withstand operational stresses, including shock loads.

Generators

- Simulate electromagnetic performance for efficient energy generation, optimizing design and power conversion.

- Perform thermal analysis to maintain consistent performance and prevent overheating during operations.

Relevant Ansys Software

Relevant ANSYS software for wind turbines includes ANSYS Fluent, Mechanical, and CFX. These tools provide advanced simulations for aerodynamics, structural integrity, and system-level performance to optimize wind turbine design and efficiency.

Assists in designing wind turbine blades, optimizing their aerodynamic profiles to reduce drag and increase lift.

Aerodynamics design and analysis for turbomachinery.

Explicit simulation for crash, impact, and nonlinear events.

Ansys Composite PrepPost

Models composite materials used in lightweight wind turbine blades to enhance strength and fatigue resistance.

Ansys Composite Cure Simulation

Simulates the curing process of composite blades, predicting residual stresses and ensuring high-quality manufacturing.

Material selection for performance, cost, and sustainability.

Wave and Tidal Energy Conversion Systems

ANSYS Wave and Tidal Energy Conversion Systems provide advanced simulation tools for optimizing the design and performance of renewable ocean energy devices. These solutions analyze hydrodynamics, structural integrity, and system interactions to maximize efficiency and reliability.

Thermal analysis to prevent overheating of components in energy systems exposed to environmental stresses.

Structural analysis to ensure the durability of components under dynamic ocean conditions, including varying wave heights, tidal forces, and water pressures.

Fatigue and corrosion analysis for long-term durability of components exposed to harsh marine environments.

Hydrodynamic simulations to optimize energy capture from waves and tides, improving the efficiency of energy conversion systems.

Component-Level Capabilities

ANSYS Wave and Tidal Energy Conversion Systems component-level capabilities enable detailed simulation of individual components like turbines, generators, and buoy structures. These tools optimize hydrodynamic, structural, and fatigue performance for improved efficiency and longevity.

Wave Energy Converters

- Simulate hydrodynamic performance for optimal energy capture and conversion from ocean waves.

- Perform structural analysis to ensure resilience against high wave forces, corrosion, and fatigue.

Tidal Energy Systems

- Simulate tidal flow and optimize the placement and performance of energy conversion systems.

- Conduct structural integrity analysis to withstand varying tidal forces and long-term exposure to seawater conditions.

Mooring Systems

- Conduct stress analysis on mooring components to ensure secure anchoring of wave and tidal energy converters.

- Perform corrosion analysis to ensure the long-term reliability of mooring systems in marine environments.

Power Cables

- Perform thermal analysis to ensure efficient power transmission from energy systems to shore-based facilities.

- Evaluate the structural integrity of power cables under underwater deployment conditions, ensuring resilience to tension, abrasion, and corrosion.

Relevant Ansys Software

Relevant ANSYS software for wave and tidal energy conversion systems includes ANSYS AQWA, Fluent, and Mechanical. These tools facilitate simulations of fluid-structure interactions, hydrodynamics, and structural integrity to optimize energy conversion performance and design.

Simulates wave loading, hydrodynamic behaviour, and mooring systems for wave and tidal energy devices, ensuring stability and performance in marine environments.

Ansys Composite PrepPost

Models composite materials used in floats, blades, and structures to optimize strength and reduce weight for improved performance in harsh marine environments.

Ansys Composite Cure Simulation

Simulates the curing process of composite components, predicting residual stresses and deformations to ensure manufacturing quality.

Fatigue life prediction for durability engineering.

Electromagnetic field simulation for motors and actuators.

Geothermal Systems

ANSYS Geothermal Systems solutions provide advanced simulation tools for optimizing the design and performance of geothermal energy systems. These tools analyze heat transfer, fluid dynamics, and structural integrity to enhance efficiency and sustainability in geothermal energy production.

Thermal simulations to optimize heat extraction and dissipation, maximizing the efficiency of geothermal energy systems.

Structural analysis to ensure the durability of machine components under extreme heat and pressure conditions.

Fluid dynamics for efficient fluid flow in geothermal systems, ensuring efficient energy conversion.

Corrosion analysis of materials exposed to high temperatures and aggressive geothermal fluids, ensuring long-term reliability of system components.

Component-Level Capabilities

ANSYS Geothermal Systems component-level capabilities enable detailed simulation of components like wells, heat exchangers, and piping. These tools optimize thermal, fluid, and structural performance to improve efficiency, longevity, and reliability in geothermal energy systems.

Heat Exchangers

- Perform thermal analysis for efficient heat transfer between geothermal fluids and the energy extraction system.

- Simulate corrosion in the pipelines of the heat exchanger due to the flow of mineral-rich geothermal water.

Pumps

- Test fluid dynamics for efficient fluid movement, ensuring proper circulation of geothermal fluids.

- Conduct stress and fatigue analysis of pump components to assess their ability to withstand high-temperature, high-pressure conditions.

Piping Systems

- Simulate fluid flow through pipelines, optimizing pipe design for minimal energy loss.

- Analyze structural components for corrosion resistance in harsh geothermal conditions.

Turbines

- Conduct computational fluid dynamics of turbine blades for efficient energy conversion.

- Perform thermal analysis to prevent overheating of turbines during continuous operation.

Reinjection Wells

- Simulate thermal and fluid dynamics for efficient reinjection of condensed fluids into the geothermal reservoir.

- Analyze structural strength to ensure safe and effective long-term use of geothermal reinjection systems.

Relevant Ansys Software

Relevant ANSYS software for geothermal systems includes ANSYS Fluent, Mechanical, and CFX. These tools provide comprehensive simulations of heat transfer, fluid dynamics, and structural behavior to optimize geothermal energy system performance and design.

Material selection for performance, cost, and sustainability.

Hydropower Systems

ANSYS Hydropower Systems solutions provide advanced simulation tools for optimizing the design and performance of hydropower plants. These tools analyze fluid dynamics, structural integrity, and mechanical performance to enhance efficiency, reliability, and sustainability in hydropower generation..

Thermal simulations to optimize heat dissipation and prevent overheating of sensitive equipment, such as electrical generators and control systems.

Structural analysis to assess the durability of hydropower components, ensuring they can withstand immense water pressure and dynamic loading conditions.

Fluid dynamics simulations to optimize water flow and energy conversion, maximizing the efficiency of turbines and minimizing energy losses.

Vibration analysis to reduce the risk of fatigue failures, and minimize noise levels.

Component-Level Capabilities

ANSYS Hydropower Systems component-level capabilities enable detailed simulation of turbine blades, generators, and penstocks. These tools optimize fluid dynamics, structural integrity, and mechanical performance to improve efficiency and reliability in hydropower systems.

Turbines

- Simulate fluid dynamics to optimize turbine blade and rotor design, ensuring maximum energy generation efficiency.

- Analyze the structural strength of turbine components to ensure they can endure high water pressure, dynamic loading, and fatigue over long periods.

Dams

- Test the structural strength of dams to ensure stability under immense water pressures.

- Perform fatigue and fracture analysis to assess the effects of seismic activity on the resilience of the dam.

Pumping Stations

- Simulate fluid dynamics to optimize pump performance, ensuring efficient water movement through hydropower systems.

- Analyze structural components to assess their reliability under high-pressure conditions and varying water flow rates, ensuring safe and efficient operation.

Powerhouses

- Test vibration effects on turbine systems and other equipment to optimize performance and prevent damage from mechanical oscillations.

- Perform thermal analysis to prevent overheating of critical components inside the powerhouse.

Spillways

- Simulate fluid flow in spillways to ensure safe and controlled water release, maintaining dam stability.

- Analyze structural strength under high flow rates to ensure spillways can handle extreme water volumes without failure.

Relevant Ansys Software

Relevant ANSYS software for hydropower systems includes ANSYS Fluent, Mechanical, and AQWA. These tools provide simulations for fluid dynamics, structural integrity, and wave dynamics to optimize hydropower system design and performance.

Advanced CFD for turbomachinery and rotating equipment.

Aerodynamics design and analysis for turbomachinery.

Designs and optimizes turbine blades for improved hydraulic performance and reduced energy losses.

Ansys Composite PrepPost

Models composite materials used in lightweight and corrosion-resistant components, such as turbine blades and pipes.

interested in our Product or Solution

Still have a Question?

FAQ

How does ANSYS support the energy industry?

ANSYS enables simulation of energy systems and components—such as turbines, heat exchangers, batteries, and power electronics—to improve efficiency, reliability, and performance.

Can ANSYS be used for renewable energy applications?

Yes, ANSYS supports wind, solar, hydro, and battery technologies by simulating structural loads, thermal effects, fluid dynamics, and energy conversion processes.

How does ANSYS help reduce operational risks in energy systems?

By predicting stress, fatigue, thermal behavior, and failure modes, ANSYS helps engineers design safer and longer-lasting energy infrastructure.

Is ANSYS useful for power grid and electronics simulation?

Absolutely. ANSYS can simulate electromagnetic fields, thermal management, and power electronics behavior for grid components, inverters, and transformers.

Can ANSYS help with sustainability and regulatory compliance?

Yes, ANSYS helps optimize designs for energy efficiency and emission control, supporting clean energy goals and helping meet environmental regulations.

Transform Ideas into Reality—Explore Our Simulation Solutions Today!

Partner with Us to Revolutionize Engineering Excellence!

Testimonials