Industries

Marine and Offshore

Simulating the Future of Transportation and Mobility

Exponentially innovate to deliver the transportation and mobility experiences of the future with the next generation of simulation and engineering tools.

Cut costs & innovate

quickly with simulation

The marine and offshore industry is integral to global trade, energy production, and underwater exploration. Engineers in this sector face unique challenges such as ensuring the structural integrity of vessels, combating corrosion, and optimizing propulsion systems. Ansys provides simulation solutions to address these needs: Ansys Mechanical for structural and thermal analysis, Ansys Fluent for fluid dynamics, Ansys Aqwa for hydrodynamic analysis, Ansys LS-DYNA for impact and collision simulations, Ansys HFSS for electromagnetic field simulations, and Ansys Granta for materials information management. These tools help engineers design, analyze, and optimize marine and offshore structures for safety, efficiency, and sustainability.

- Electric Vehicles

- Vehicle Engineering

- Simulation Solutions

- Simulation Solutions

- ADAS & Autonomous Vehicles

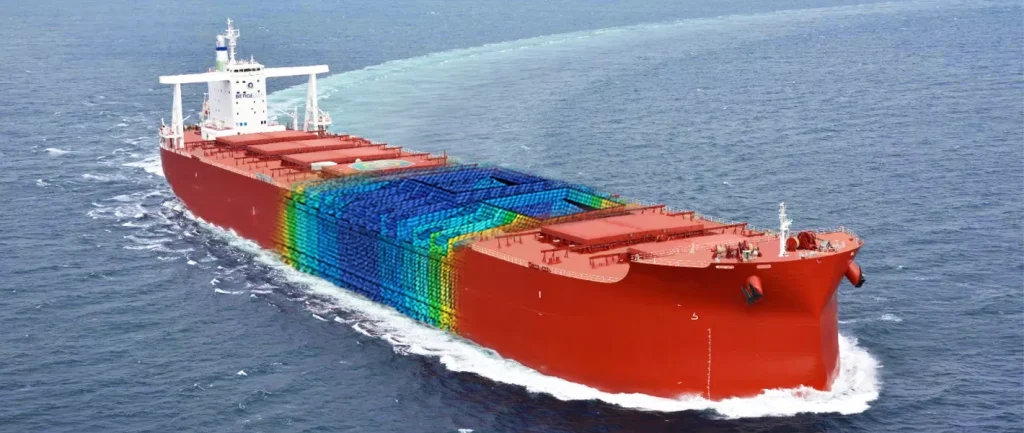

Ship Hull Design

ANSYS Ship Hull Design provides powerful tools for modeling, simulating, and optimizing hull structures for maximum hydrodynamic performance. It enables engineers to predict structural behavior, minimize resistance, and enhance vessel efficiency.

Structural analysis to ensure durability and safety under various load conditions, including wave impact and cargo stress.

Hydrodynamic and fluid flow simulations to optimize hull performance and reduce drag for improved fuel efficiency.

Topology optimization for weight reduction while maintaining the required strength.

Vibration analysis to minimize the risk of fatigue and enhance stability during operation.

Component-Level Capabilities

ANSYS offers detailed component-level analysis for ship hulls, enabling precise evaluation of structural elements under real-world conditions. Engineers can optimize individual components for strength, weight, and hydrodynamic efficiency

Hull Plates

- Simulate hydrodynamic performance for reducing drag and optimizing fuel consumption.

- Analyze structural strength to withstand high stress, impacts, and fatigue over time.

Keels

- Simulate water flow around the keel to optimize its shape for better stability and fuel efficiency.

- Perform structural analysis to assess the strength of the keel under operational loads and stresses.

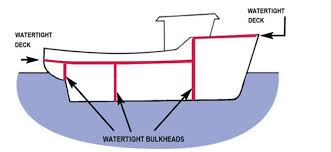

Bulkheads

- Perform structural simulations to assess bulkhead strength under dynamic loading from waves, cargo, and impact.

- Evaluate stress concentrations in bulkheads to optimize design for long-term durability in marine environments.

Rudders

- Test hydrodynamic efficiency for manoeuvrability and responsive control.

- Evaluate structural strength to withstand heavy loads and operational forces.

Deck Structures

- Simulate load-bearing capacity for cargo, equipment, and personnel under operational conditions.

- Perform fatigue analysis to evaluate deck durability under cyclic loading from operations and environmental factors.

Relevant Ansys Software

ANSYS Ship Hull Design leverages tools like ANSYS Fluent, ANSYS Mechanical, and ANSYS AQWA for comprehensive fluid-structure interaction and hydrodynamic analysis. These solutions enable accurate modeling, performance prediction, and structural optimization of ship hulls

Simulates hydrodynamic behaviour, including wave loading, stability, and dynamic motion of ship hulls in offshore environments.

Ansys Composite PrepPost

Models composite materials used in lightweight hull designs to optimize strength and reduce weight.

Subsea Structures

ANSYS Subsea Structures solutions enable accurate simulation of offshore components under extreme underwater conditions. Engineers can assess structural integrity, fatigue life, and hydrodynamic performance for safer, more reliable designs

Structural analysis for the durability and stability of subsea installations under extreme underwater pressures and environmental conditions.

Fluid dynamics for efficient flow of fluids and interaction with underwater currents.

Corrosion simulations to predict material degradation due to harsh underwater conditions.

Vibration analysis to ensure stability and performance in dynamic subsea environments.

Performance testing under various subsea conditions including varying temperatures and pressures.

Component-Level Capabilities

ANSYS provides detailed component-level analysis for subsea structures, addressing stresses, fatigue, and thermal effects in harsh environments. This ensures optimized design and enhanced reliability of critical underwater components

Pipelines

- Analyze structural integrity to prevent leaks, cracks, and failures in extreme subsea conditions.

- Simulate fluid dynamics for efficient oil, gas, and fluid transport, minimizing losses and ensuring reliability.

Manifolds

- Test structural strength for high-pressure operation in subsea environments.

- Evaluate material resistance to corrosion, ensuring long-term operational reliability.

Foundations

- Assess hydrodynamic forces and their impact on subsea foundation stability during extreme oceanic events.

- Model thermal and mechanical stresses to validate performance under varying temperature and pressure conditions at depth.

Risers

- Test hydrodynamic performance to ensure efficient fluid transport from seabed to surface.

- Analyze structural components for durability against dynamic marine conditions and fatigue.

Wellheads

- Simulate structural integrity for reliable operation and secure containment of subsea fluids.

- Analyze corrosion resistance and material properties for an extended service life in hostile environments.

Relevant Ansys Software

ANSYS Subsea Structures workflows use tools like ANSYS Mechanical, ANSYS Aqwa, and ANSYS Fluent to simulate structural, thermal, and hydrodynamic behavior. These solutions ensure accurate analysis and robust design of critical subsea components.

Models hydrodynamic behaviour, including wave loading, stability, and dynamic motion of subsea structures under varying ocean conditions.

Ansys Composite PrepPost

Models composite materials used in subsea structures for lightweight and corrosion-resistant designs, optimizing strength and durability.

Offshore Platforms

ANSYS Offshore Platforms solutions enable comprehensive simulation of structural, hydrodynamic, and environmental loads on offshore structures. Engineers can optimize platform designs for strength, stability, and long-term durability in harsh marine conditions.

Structural analysis for ensuring the stability and safety of offshore platforms under dynamic marine conditions.

Corrosion and material degradation analysis to ensure long-term durability in harsh marine environments.

Simulation of fluid-structure interactions to evaluate wave impact and reduce the risk of structural damage.

Vibration testing to minimize the risk of fatigue and optimize stability for safe and efficient operations.

Performance testing under environmental conditions such as heavy winds, waves, and seismic activity.

Component-Level Capabilities

ANSYS provides detailed component-level analysis for offshore platforms, evaluating structural elements under complex load conditions. This ensures optimized performance, safety, and durability of critical offshore components.

Deck Structures

- Evaluate stress distribution to ensure safe support of platform equipment, personnel, and operational loads.

- Analyze material corrosion for long-term durability in exposure to saltwater and wind.

Jackets and Legs

- Test structural strength and stability for underwater installation and long-term operation.

- Evaluate corrosion resistance to extend the lifespan of platform legs and structures.

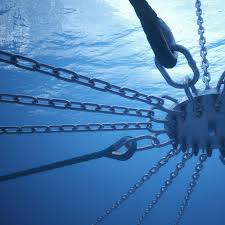

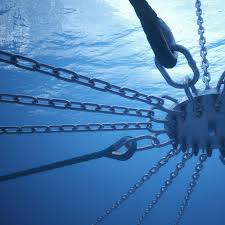

Mooring Systems

- Simulate hydrodynamic performance for reliable and secure anchoring of floating platforms.

- Assess mooring line tension and fatigue life to ensure reliability under varying environmental and operational conditions.

Living Quarters

- Test structural integrity for the safety and comfort of crew members.

- Assess ventilation and airflow dynamics to ensure optimal air quality and environmental comfort within living quarters.

Helidecks

- Simulate load-bearing capacity to safely support helicopter operations.

- Evaluate dynamic response and vibration characteristics during takeoff and landing to ensure safety and structural stability.

Relevant Ansys Software

ANSYS solutions like ANSYS Mechanical, ANSYS Aqwa, and ANSYS Fluent support offshore platform design through structural, hydrodynamic, and environmental simulations. These tools help ensure platform safety, performance, and regulatory compliance.

Finite element analysis for structural performance.

Ansys Aqwa

Models hydrodynamic behaviour, including wave loading, dynamic motion, and stability of offshore platforms under harsh marine conditions.

Ansys Composite PrepPost

Models composite materials used in offshore platform components, optimizing for strength and lightweight durability in corrosive environments.

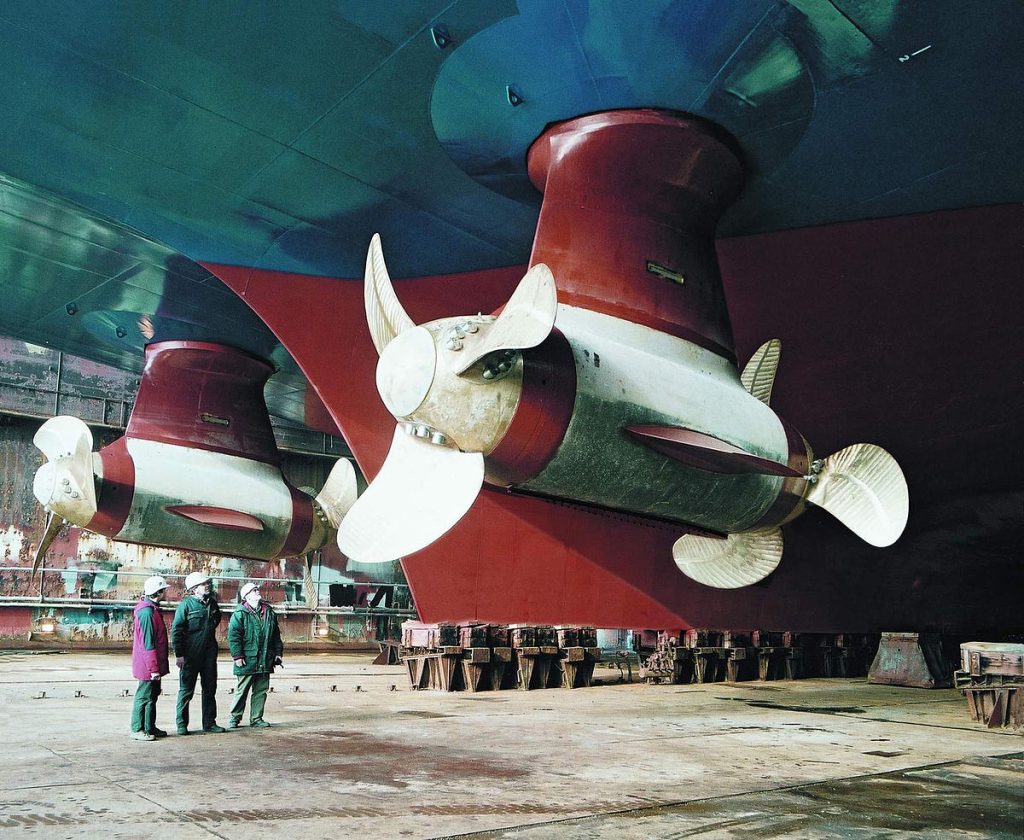

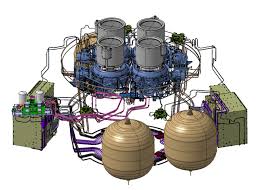

Propulsion Systems

ANSYS Propulsion Systems provides advanced simulation tools for analyzing and optimizing propulsion components, ensuring efficiency and reliability. Engineers can model fluid dynamics, thermal effects, and mechanical performance to enhance system design.

Structural analysis for durability, reliability, and safe operation of propulsion components under dynamic loads.

Vibration analysis to reduce noise and the risk of fatigue.

Computational fluid dynamics simulations for propeller and thruster design to maximize performance and performance.

Performance testing to simulate operational conditions and identify areas for improvement.

Thermal analysis to prevent overheating of propulsion components, ensuring long-term operation.

Component-Level Capabilities

ANSYS offers detailed component-level analysis for propulsion systems, enabling optimization of individual parts like engines, turbines, and propellers. This ensures improved performance, durability, and efficiency across all system components.

Propellers and Thrusters

- Simulate fluid flow performance to optimize thrust and reduce fuel consumption.

- Evaluate the impact of cavitation and erosion on propeller performance and longevity in marine environments.

Engines

- Simulate thermal performance to optimize combustion efficiency and prevent overheating.

- Analyze vibration effects to minimize noise and reduce the risk of fatigue failure of components.

Shafts

- Test structural strength for reliable power transmission between engine and propeller.

- Assess resilience to shock loads to ensure shaft integrity during sudden changes in operational conditions.

Gearboxes

- Evaluate structural strength under high torque and shock loading to ensure durability and reliable performance in ship propulsion.

- Simulate lubrication effects to enhance the efficiency of gearbox systems.

Relevant Ansys Software

ANSYS Propulsion Systems integrates tools like ANSYS Fluent, ANSYS Mechanical, and ANSYS CFX to simulate fluid dynamics, structural integrity, and thermal effects. These solutions enable precise design and optimization of propulsion components for superior performance.

Ansys BladeModeler

Assists in the design and optimization of propeller blades, improving hydrodynamic performance and reducing cavitation risks.

Simulates hydrodynamic interactions with propellers, evaluating overall system performance under wave loading conditions.

Ansys Composite PrepPost

Models composite materials used in lightweight and corrosion-resistant propeller blades, optimizing for strength and durability.

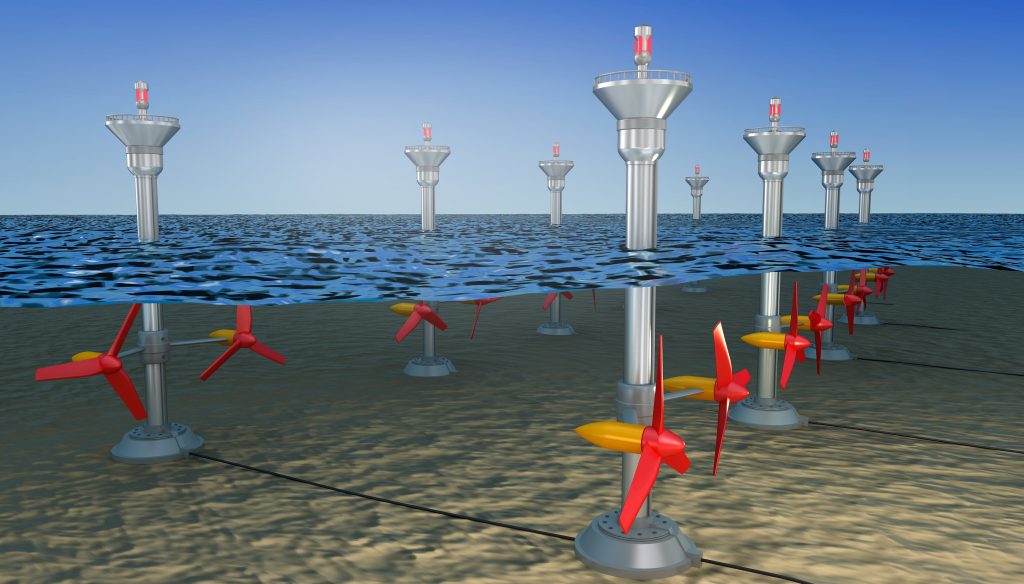

Marine Renewable Energy Systems

ANSYS Marine Renewable Energy Systems provides advanced simulation tools to optimize the design and performance of wave, tidal, and offshore wind energy systems. Engineers can analyze fluid-structure interactions, durability, and energy efficiency in harsh marine environments.

Structural analysis to ensure durability and reliability in harsh marine environments.

Thermal analysis to optimize performance in energy systems operating in varying thermal conditions.

Hydrodynamic simulations for energy conversion efficiency in tidal energy harvesting technologies.

Corrosion analysis to evaluate material degradation and ensure long-term reliability.

Component-Level Capabilities

ANSYS offers detailed component-level analysis for marine renewable energy systems, focusing on structural integrity, fatigue, and hydrodynamic performance. This ensures optimized design and long-term reliability of individual components in challenging ocean environments.

Tidal Turbines

- Simulate hydrodynamic performance to maximize energy conversion efficiency.

- Perform structural analysis on the components to withstand marine conditions and dynamic loading.

Wave Energy Converters

- Simulate hydrodynamic performance for optimal wave force absorption and conversion efficiency under varying sea conditions.

- Analyze fatigue resistance to ensure long-term reliability and performance under cyclic loading from wave forces.

Mooring Systems

- Analyze stress and strain on mooring systems to ensure secure anchoring of floating renewable energy systems.

- Evaluate corrosion resistance for long-term operation in marine environments.

Power Cables

- Simulate thermal performance for efficient power transmission from offshore installations.

- Analyze structural integrity for long-term underwater deployment.

Relevant Ansys Software

ANSYS Marine Renewable Energy Systems leverages tools like ANSYS Aqwa, ANSYS Fluent, and ANSYS Mechanical to model fluid-structure interactions, dynamic loads, and environmental effects. These solutions ensure the efficient and reliable design of renewable energy systems in marine environments.

Ansys Aqwa

Simulates wave loading, hydrodynamic stability, and motion behaviour of floating and fixed marine energy systems under various marine conditions.

Ansys Composite PrepPost

Models composite materials used in lightweight and corrosion-resistant components, such as blades and platforms, optimizing strength and longevity.

Autonomous Underwater Vehicles (AUVs)

ANSYS solutions enable the design and optimization of Autonomous Underwater Vehicles (AUVs) by simulating fluid dynamics, structural integrity, and control systems. Engineers can enhance vehicle performance, endurance, and reliability in complex underwater environments.

Structural analysis to ensure durability under extreme underwater pressure.

Thermal simulations to prevent overheating of critical components, including electronics.

Vibration analysis to enhance stability and reduce the risk of fatigue.

Hydrodynamic simulations to optimize AUV performance and propulsion efficiency.

Simulation of embedded software performance to ensure reliability and responsiveness of control systems.

Component-Level Capabilities

ANSYS provides detailed component-level analysis for Autonomous Underwater Vehicles, optimizing individual parts such as thrusters, sensors, and hull structures. This ensures enhanced performance, durability, and reliability in challenging underwater conditions.

Hull Structures

- Simulate hydrodynamic performance to optimize hull design for efficient movement.

- Analyze structural strength under dynamic water pressures and impact forces to ensure durability and safe operation.

Propulsion Systems

- Simulate fluid dynamics to optimize propulsion system performance and energy efficiency in varying water conditions.

- Evaluate vibration effects to optimize stability and minimize noise levels.

Navigation Systems

- Simulate acoustic performance to optimize sonar signal propagation in underwater navigation systems.

- Perform thermal analysis to prevent overheating of sensitive navigation equipment.

Battery Systems

- Test thermal performance for reliable power supply and optimal energy efficiency.

- Simulate electrochemical reactions to optimize battery performance efficiency.

Automation and Embedded Systems

- Assess EMI/EMC to ensure reliable operation and minimize interference in AUV electronics.

- Evaluate embedded software design to ensure reliable coding and performance of control algorithms.

Sensors and Actuators

- Perform electromagnetic analysis to optimize sensor performance and response in different operational conditions.

- Analyze signal integrity to ensure accurate data transmission and minimize interference over time.

Relevant Ansys Software

ANSYS solutions like ANSYS Fluent, ANSYS Mechanical, and ANSYS Autodyn support the design and optimization of Autonomous Underwater Vehicles. These tools enable precise simulations of fluid dynamics, structural integrity, and dynamic interactions in underwater environments.

Models hydrodynamic behaviour and wave interactions for AUVs in dynamic ocean conditions, ensuring stability and operational performance.

Explicit simulation for crash, impact, and nonlinear events.

Ansys SCADE Suite

Ansys Composite PrepPost

Models composite materials used in lightweight, corrosion-resistant AUV frames and hulls, optimizing for strength and durability.

Ansys RedHawk-SC

Provides full-chip power integrity, voltage drop, and electromigration analysis for advanced ICs in AUV control systems, ensuring reliable and efficient electronic operation.

Navigation and Communication Systems

ANSYS provides advanced simulation tools to optimize the design and performance of navigation and communication systems. Engineers can model signal propagation, system integrity, and performance in various operational environments to ensure reliability and precision

Structural analysis to ensure the durability of navigation systems under harsh marine conditions.

Electromagnetic simulations to ensure the reliability of communication systems.

Thermal simulations to prevent overheating of sensitive electronics.

Component-Level Capabilities

ANSYS enables detailed component-level analysis for navigation and communication systems, optimizing elements like antennas, sensors, and signal processors. This ensures enhanced reliability, performance, and robustness for individual components in complex operational conditions.

Radars

- Simulate electromagnetic performance for accurate detection and tracking.

- Analyze structural resilience for sustained performance in harsh marine environments.

Antennas

- Test antenna-to-antenna interference, and perform design changes to enhance accuracy.

- Perform electromagnetic analysis to achieve the best design possible for the application.

GPS Systems

- Simulate electromagnetic interference (EMI) to ensure accurate positioning and signal integrity in challenging environments.

- Conduct thermal analysis to maintain performance and accuracy under varying environmental conditions.

Communication Modules

- Perform electromagnetic simulations to optimize antenna design, and signal propagation, and minimize interference.

- Analyze structural integrity to assess durability and reliability in harsh marine conditions.

Relevant Ansys Software

ANSYS tools like ANSYS HFSS, ANSYS Maxwell, and ANSYS Electronics Desktop provide advanced simulations for optimizing navigation and communication systems. These solutions enable precise modeling of electromagnetic behavior, signal integrity, and component performance in diverse environments.

Provides power integrity, voltage drop, and electromigration analysis for advanced IC designs in navigation and communication devices, ensuring reliable electronic operation

Ansys SCADE Suite

Shipyard Facility

ANSYS Shipyard Facility provides advanced simulation tools to optimize shipyard operations, including design, manufacturing, and assembly processes. Engineers can streamline workflows, reduce costs, and improve the quality and efficiency of shipbuilding projects..

Structural analysis for the durability of shipbuilding facilities and equipment under heavy loads and dynamic conditions.

Fatigue analysis to assess the long-term performance and safety of structural components exposed to repetitive stress.

Vibration analysis to optimize equipment performance and reduce the risk of structural resonance or failure.

Thermal analysis to ensure that temperature fluctuations do not negatively impact facility operations or equipment lifespan.

Corrosion simulation to evaluate the impact of environmental factors on the longevity of materials.

Component-Level Capabilities

ANSYS offers detailed component-level analysis for shipyard facilities, enabling optimization of individual elements such as cranes, fabrication tools, and assembly structures. This ensures enhanced efficiency, safety, and precision during the shipbuilding process.

Dry Docks

- Simulate load-bearing capacity for various ship sizes and weights during docking and maintenance.

- Perform fatigue analysis on structures exposed to repetitive loading cycles.

Cranes and Hoists

- Simulate lifting dynamics and kinematics to optimize safe handling of heavy components.

- Perform structural analysis to evaluate durability and performance under mechanical stress and shock loads.

Hydraulic Systems

- Simulate fluid dynamics to optimize the performance of shipbuilding equipment and machinery.

- Perform structural and fatigue analysis on hydraulic components to ensure long-term durability under pressure.

Relevant Ansys Software

ANSYS Shipyard Facility utilizes tools like ANSYS Mechanical, ANSYS Fluent, and ANSYS AQWA to simulate structural integrity, fluid dynamics, and environmental effects. These solutions help optimize shipyard operations, ensuring safe, efficient, and high-quality shipbuilding processes.

interested in our Product or Solution

Still have a Question?

FAQ

How is ANSYS used in the marine and offshore industry?

ANSYS helps simulate structural integrity, hydrodynamics, and environmental loads on ships, offshore platforms, and underwater equipment to ensure performance and safety.

Can ANSYS simulate fluid-structure interaction for marine systems?

Yes, ANSYS provides advanced capabilities for simulating wave loading, sloshing, buoyancy, and interactions between water and structural components.

How does ANSYS support offshore structure design?

ANSYS helps design and validate platforms, risers, pipelines, and subsea components under harsh conditions such as high pressure, strong currents, and extreme weather.

Is ANSYS suitable for ship design optimization?

Absolutely. ANSYS enables naval architects to optimize hull forms for hydrodynamic efficiency, fuel savings, and stability, reducing operational costs.

Can ANSYS help with compliance to maritime regulations?

Yes, ANSYS simulations support verification against international standards like DNV, ABS, and IMO, streamlining certification and reducing physical testing.

Transform Ideas into Reality—Explore Our Simulation Solutions Today!

Partner with Us to Revolutionize Engineering Excellence!

Testimonials