Industries

Material and Chemical Processing

Simulating the Future of Transportation and Mobility

Exponentially innovate to deliver the transportation and mobility experiences of the future with the next generation of simulation and engineering tools.

Cut costs & innovate

quickly with simulation

The material and chemical processing industry focuses on converting raw materials into valuable products through various chemical, physical, and mechanical methods. Ansys provides a comprehensive suite of simulation tools that support every aspect of the manufacturing process. Ansys Mechanical enables detailed structural analysis, Ansys Fluent offers advanced fluid flow, heat transfer and corrosion simulations, Ansys CFX is specialized for turbomachinery applications, Ansys Polyflow supports polymer processing, Ansys Granta helps manage materials data, and Ansys Chemkin-Pro simulates combustion reactions. These solutions not only optimize processes but also aid in product design, improve safety, reduce costs, and enhance sustainability across production systems.

- Electric Vehicles

- Vehicle Engineering

- Simulation Solutions

- ADAS & Autonomous Vehicles

Glass

ANSYS GLASS is a specialized simulation tool for modeling and analyzing glass structures under various thermal and mechanical loads. It enables accurate prediction of stress, breakage, and performance in architectural, automotive, and electronic glass applications.

Thermal simulations to analyze temperature distribution and thermal stresses developed in glass and manufacturing equipment.

Structural analysis on glass to assess load-carrying capacity under various operational conditions, including impacts.

Fluid dynamics for efficient flow and mixing of raw materials during glass formation.

Vibration and fatigue analysis on glass components to ensure they withstand repeated cyclic loads.

Component-Level Capabilities

ANSYS GLASS Component-Level Capabilities provide detailed analysis of individual glass components, including stress distribution, thermal response, and fracture risk. These capabilities help ensure reliability and safety in complex glass designs across industries.

Furnaces

- Simulate heat transfer to enhance the melting process and energy efficiency.

- Simulate combustion reactions to ensure efficient burning of fuel with less formation of soot.

Glass Forming Machines

- Analyze material flow to achieve uniform shaping and reduce inconsistencies.

- Perform thermo-structural analysis on machine parts to ensure they withstand operational loads.

Glass Containers

- Test structural strength to withstand impact and pressure under varied conditions.

- Simulate light propagation and reflection characteristics of glass containers to optimize visual properties.

Relevant Ansys Software

ANSYS GLASS integrates with relevant Ansys software like Mechanical, Fluent, and LS-DYNA to simulate thermal, structural, and impact behaviors of glass. This interoperability ensures comprehensive, high-fidelity analysis across various loading scenarios.

Metal

ANSYS METAL offers advanced simulation tools for analyzing the behavior of metal components under mechanical, thermal, and fatigue loads. It supports accurate material modeling, helping optimize performance and durability in metal-based designs.

Structural analysis to ensure metal products meet design specifications and performance standards.

Thermal analysis to assess the response of metal components under various thermal loads.

Simulate sheet metal forming processes to optimize the design, assess spring-back effects, and reduce material waste.

Vibration analysis to reduce the risk of fatigue and improve stability in metal components.

Component-Level Capabilities

ANSYS METAL Component-Level Capabilities enable detailed analysis of individual metal parts, including stress, strain, fatigue, and failure predictions. These tools support robust design and validation for high-performance metal components.

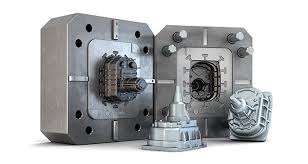

Casting Moulds

- Simulate molten metal flow to assess and minimize defects such as air pockets.

- Perform thermal analysis to assess the thermal expansion and stresses developed in the mould.

Forging Dies

- Assess the structural strength of forging dies under high-pressure conditions.

- Perform fatigue analysis to evaluate the effects of repeated loading during forging operations.

Heat Treatment Furnaces

- Perform thermo-structural analysis and heat transfer on furnace components to evaluate effectiveness.

- Simulate combustion reaction processes for efficient burning of fuel.

Sheet Metal Forming

- Simulate the forming processes to evaluate metal response including stresses developed, spring-back effect, etc.

- Perform structural analysis on the dies to ensure they can tolerate the high loads involved.

Welding Processes

- Model spot and seam welds to join various metal components together in large assemblies.

- Evaluate stresses developed in the structure due to operational loads, including the effects of welds and the heat-affected zones.

Relevant Ansys Software

ANSYS METAL leverages tools like Ansys Mechanical, LS-DYNA, and Ansys Fluent for comprehensive analysis of metal behavior under structural, impact, and thermal conditions. This integration ensures accurate simulation across diverse engineering applications.

Optimizes combustion processes in furnaces used for metal processing, enhancing fuel efficiency and emission control.

Mining

ANSYS Mining provides simulation solutions to optimize equipment performance, structural integrity, and safety in mining operations. It enables virtual testing of machinery, materials, and processes under harsh environmental and load conditions.

Structural analysis to ensure the safety and durability of mining equipment and infrastructure.

Fluid dynamics simulations for efficient material transport, slurry handling, and ventilation in mines.

Vibration analysis to improve stability and reduce the risk of fatigue in critical components.

Thermal analysis and heat transfer to assess thermal stresses and prevent overheating in mining machinery.

Component-Level Capabilities

ANSYS Mining Component-Level Capabilities deliver precise analysis of individual mining equipment parts, focusing on durability, wear, and structural performance. These simulations help enhance reliability and extend the lifespan of critical components.Ansys 5G simulation solutions provide electromagnetics, semiconductor, electronics cooling and mechanical analysis tools to accurately simulate 5G communications technologies.

Crushers and Mills

- Assess the structural strength of crushers and mills to withstand high operational stresses.

- Perform vibration and fatigue analysis on the machine components to assess their durability.

Conveyor Systems and Separation Equipment

- Analyze load distribution and stresses generated to ensure smooth and efficient transport of materials.

- Use discrete element modelling (DEM) to simulate particle motion, interactions, and flow characteristics during the transport of bulk materials.

Excavators and Drills

- Perform structural analysis to evaluate stresses generated during operation, including the effects of shock loads.

- Analyze vibration effects to enhance equipment stability and reduce the risk of fatigue failure.

Mine Ventilation Systems

- Simulate airflow dynamics for improved ventilation and worker safety in mines.

- Simulate heat transfer to maintain a safe working temperature inside mines.

Relevant Ansys Software

ANSYS Mining integrates with software like ANSYS Mechanical, Fluent, and Discovery to model complex mining operations and equipment behavior. This combination ensures accurate simulations for mechanical, thermal, and fluid dynamics challenges in the mining industry.

Process Equipment

ANSYS Process Equipment offers simulation tools to optimize the design and performance of equipment used in chemical, oil, and gas industries. It helps analyze stress, thermal, and fluid behavior to ensure reliability and efficiency in complex processing systems.

Structural analysis to ensure the durability and operational reliability of process equipment.

Fluid dynamics simulations to optimize mixing, flow, and heat transfer in industrial processes.

Thermal analysis for efficient heating and cooling in process systems.

Vibration analysis to reduce the risk of fatigue and improve stability in equipment operations.

Acoustic simulations to evaluate and reduce noise levels in various process equipment machinery.

Component-Level Capabilities

ANSYS Process Equipment Component-Level Capabilities provide detailed simulations of individual parts within process systems, focusing on thermal, mechanical, and fluid dynamics. These tools ensure optimal performance, safety, and longevity of critical equipment components.

Reactors

- Simulate fluid dynamics to optimize the mixing of different fluids for efficient processing.

- Analyze thermal characteristics to ensure optimal reaction conditions and energy efficiency.

Heat Exchangers

- Perform thermo-structural analysis to analyze the thermal expansion and stresses developed in machine parts.

- Simulate fluid flow to ensure efficient heat transfer and optimal operating conditions.

Distillation Columns

- Simulate fluid flow dynamics of the distillation process to enhance separation efficiency.

- Conduct thermal and heat transfer analysis to maintain consistent operation.

Mixing Vessels

- Test mixing efficiency using fluid dynamics to ensure uniformity and consistency in the final product.

- Assess the structural strength of mixing vessels under various operational conditions to ensure long-term performance.

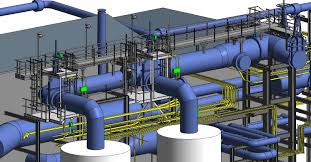

Piping Systems

- Simulate fluid dynamics to optimize transport efficiency and minimize pressure loss.

- Simulate erosion of pipe material due to fluid flow, to enhance the operational life of piping systems.

Relevant Ansys Software

ANSYS Process Equipment integrates with software like ANSYS Mechanical, Fluent, and AIM to analyze complex behaviors in process systems. This integration provides accurate simulations of mechanical, fluid, and thermal performance for efficient process equipment design.

Advanced Materials

ANSYS Advanced Materials offers simulation tools to model the behavior of cutting-edge materials under various conditions, including thermal, mechanical, and electromagnetic stresses. It enables the design of high-performance components using complex material models for industries like aerospace and electronics.

Structural analysis to design advanced materials with improved mechanical properties.

Thermal analysis to enhance material performance in various applications under a range of temperatures.

Fluid dynamics simulation for efficient production and processing of advanced materials.

Component-Level Capabilities

ANSYS Advanced Materials Component-Level Capabilities enable detailed simulations of individual material components, focusing on their mechanical, thermal, and electrical properties. These tools help optimize performance and reliability in the design of high-performance material systems.

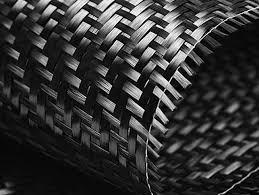

Composites

- Model fibre orientation and ply stacking in composite materials to optimize performance and strength.

- Analyze the structural strength of components for various composite applications.

Nanomaterials

- Simulate the dispersion of nanoparticles in a fluid using fluid dynamics to ensure effective mixing.

Ceramics

- Simulate thermal processes such as heating, cooling, and thermal cycling to assess material behaviour and enhance strength.

- Analyze the mechanical behaviour of ceramics under stress to assess fracture toughness and durability.

Coatings

- Simulate the process of chemical vapour deposition (CVD) on substrates to optimize the coating characteristics.

Relevant Ansys Software

ANSYS Advanced Materials integrates with software like ANSYS Mechanical, Fluent, and Discovery to simulate the behavior of innovative materials under various conditions. This combination ensures precise analysis for designing high-performance components in industries such as aerospace and electronics.

Ansys Composite PrepPost

Provides tools for designing and simulating composite materials, ensuring optimal layer configuration for desired properties.

Ansys Composite Cure Simulation

Supports additive manufacturing for advanced materials, ensuring precise fabrication of complex geometries.

Ansys Polyflow

Optimizes the extrusion and moulding processes for polymers enhancing material properties and process efficiency.

Ansys Speos

Simulates light propagation and visual appearance, aiding in the design of materials with specific optical qualities.

Ansys Additive Suite

Supports additive manufacturing for advanced materials, ensuring precise fabrication of complex geometries.

Process Flow Optimization

ANSYS Process Flow Optimization uses advanced simulation techniques to enhance the efficiency of fluid and gas flow systems. It helps identify design improvements, reduce energy costs, and optimize process performance in industries like oil, gas, and chemical processing.

Structural analysis of piping systems to assess reliability under operational loads.

Erosion and corrosion simulation to optimize the design to enhance the life of components.

Fluid dynamics simulation for efficient flow through pipes and valves with minimal energy loss.

Thermal and heat transfer analysis to assess the thermal stresses developed and heat dissipation characteristics of system components.

Component-Level Capabilities

ANSYS Process Flow Optimization Component-Level Capabilities provide detailed analysis of individual components within fluid and gas flow systems. These tools optimize design for efficiency, reduce energy consumption, and enhance the performance of critical parts in complex process systems.

Piping Networks

- Simulate fluid dynamics to enhance transport efficiency and minimize pressure losses.

- Simulate erosion and corrosion of the inner surface of pipes to increase durability.

Heat Exchangers

- Perform fluid dynamics and heat transfer simulations to evaluate the flow of fluids and increase the effectiveness of the heat exchanger.

- Conduct thermo-structural analysis to assess the thermal stresses developed in the components of the exchanger.

Pumps and Compressors

- Simulate fluid dynamics of flow around impeller blades for maximum energy conversion efficiency.

- Simulate cavitation in pumps and compressors to make design changes to avoid damage to components.

- Perform fluid dynamics simulation to ensure proper flow and minimal energy loss due to turbulence.

- Simulate material erosion of inner walls of valves to optimize the design for enhancing the operational life.

Filters and Separators

- Simulate pressure drop due to the placement of filters in the fluid stream.

Relevant Ansys Software

ANSYS Process Flow Optimization integrates with software like ANSYS Fluent, Mechanical, and AIM to simulate and optimize fluid and gas flow behaviors. This combination ensures precise analysis and performance improvements for process systems in industries like chemical, oil, and gas.

Ansys Mechanical

Performs structural and thermal analyses on components like heat exchangers and valves to ensure durability and optimal functioning under various operating conditions.

Ansys Chemkin-Pro

Specializes in chemical reaction modelling for enhancing reactor designs within process systems, applicable where chemical reactions are integral to the process.

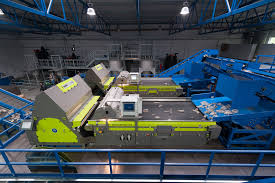

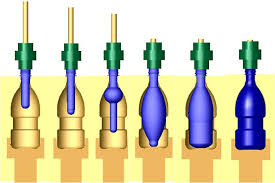

Plastic and Polymer Manufacturing Processes

ANSYS Plastic and Polymer Manufacturing Processes provide simulation tools to optimize the design and performance of plastic components during injection molding, extrusion, and other manufacturing methods. It helps improve material flow, reduce defects, and enhance the efficiency of production processes.

Manufacturing process simulation including extrusion and blow-moulding to ensure efficient production.

Structural analysis to enhance the design and durability of plastic products.

Thermal analysis and heat transfer to optimize moulding, extrusion, and other manufacturing processes.

Component-Level Capabilities

ANSYS Plastic and Polymer Manufacturing Processes Component-Level Capabilities enable detailed analysis of individual plastic parts during manufacturing. These tools optimize material flow, reduce defects, and ensure high-quality, efficient production of polymer components.

Injection and Blow Moulding

- Simulate polymer material flow to optimize mould filling and reduce product defects.

- Simulate blow moulding to ensure that the product is manufactured effectively and in high quality.

Extrusion and Thermoforming

- Simulate the extrusion process for polymer materials to ensure accurate manufacturing of parts.

- Simulate the thermoforming process to assess the behaviour of polymer parts when subjected to heating and large plastic deformations.

Relevant Ansys Software

ANSYS Plastic and Polymer Manufacturing Processes integrates with software like ANSYS Moldex3D, Fluent, and Mechanical to simulate the behavior of plastics during manufacturing. This combination ensures accurate modeling of material flow, cooling, and mechanical properties for optimized production.

interested in our Product or Solution

Still have a Question?

FAQ

How does ANSYS support the material and chemical processing industry?

ANSYS helps simulate chemical reactions, heat transfer, fluid flow, and structural behavior in processing equipment, improving efficiency, safety, and product quality.

Can ANSYS simulate complex chemical processes?

Yes, ANSYS can model multiphase flows, mixing, reaction kinetics, and thermal management to optimize reactors, separators, pipelines, and more.

How does ANSYS help with equipment reliability and safety?

ANSYS simulations predict stress, corrosion, fatigue, and thermal degradation in processing equipment, allowing for early design improvements and reduced risk of failure.

Is ANSYS useful for materials innovation?

Absolutely. ANSYS enables materials modeling at micro and macro levels to evaluate mechanical, thermal, and electrical properties—supporting the development of advanced materials.

Can ANSYS help with sustainability in chemical processing?

Yes, ANSYS supports energy efficiency, waste reduction, and emission control through process optimization and predictive modeling, contributing to more sustainable operations.

Transform Ideas into Reality—Explore Our Simulation Solutions Today!

Partner with Us to Revolutionize Engineering Excellence!

Testimonials