Products

Ansys nCode DesignLife

Stress & Strain Based Fatigue Life Prediction

Ansys nCode DesignLife, the industry-leading tool for durability analysis, gives you a comprehensive diagnostic fatigue process to predict your product’s operational lifetime.

Optimize Product Fatigue Life for Expected Use Scenarios

Ansys nCode DesignLife works with Ansys Mechanical to reliably evaluate fatigue life. Using the results of finite element analysis (FEA) from Ansys Mechanical and Ansys LS-DYNA, it accumulates damage from repetitive loading to determine a product’s predicted life. You can quickly evaluate the effects of different materials and alternative geometries for new designs, and then optimize them for the product’s expected usage — long before the first prototype is built or expensive testing takes place.

- Unparalleled Accuracy and Technology

- Simulation-Led Design to Reduce Reliance on Physical Test

- Reduce Overall Product Development & Validation Cost

- Flexible and Easy-to-Use User Interface

Features

Quick Specs

Ansys partnered with HBK to bring unparalleled simulation-based durability technology to Ansys Workbench, providing end-to-end solutions for customers finding fatigue failure a key challenge.

Still have a question?

Stress life (SN)

Thermal Mechanical Fatigue

Material Management

FEA Display

Strain life (EN)

Seam Welds

Vibration Manager

Crack growth

Vibration and fatigue

Spot Welds

Virtual Strain Gauge and Virtual Sensor

Customization

Capabilities

Understand and Simulate Fatigue Early in the Design Process

Ansys nCode DesignLife works with Ansys Mechanical and Ansys LS-DYNA to reliably evaluate fatigue life. You can quickly evaluate the effects of different materials and alternative geometries for new designs, and then optimize them for the product’s expected usage before a costly prototype.

With a new interface on the Ansys Workbench, you can enjoy a customized workflow that integrates with other products while staying within a single interface. You also have the flexibility to access your nCode user interface directly from Ansys Workbench. The ease-of-use makes the power of nCode DesignLife even easier to realize.

Capabilities

Key Features

The new user interface provides an end-to-end solution within an integrated workflow and single interface

Strain Life (EN)

Strain Life (EN)

Strain Life (EN)

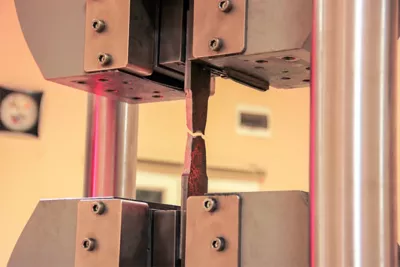

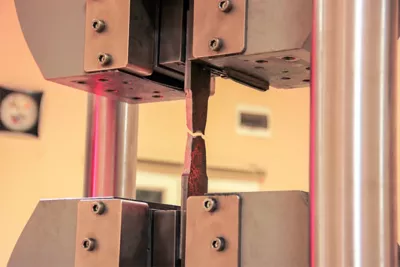

Strain Life (EN) Strain-Life is applicable to a wide range of problems, including low-cycle fatigue (LCF) where the local elastic-plastic strain controls the fatigue life.

The standard EN method uses the Coffin-Manson-Basquin formula, defining the relationship between strain amplitude and the number of cycles to failure.

Stress Life (SN)

Stress Life (SN)

Stress Life (SN)

Stress Life (SN) This is primarily applicable to high-cycle fatigue (HCF) where nominal stress controls the fatigue life.

A wide range of methods are provided for defining the SN curves, including the ability to interpolate multiple material data curves for factors such as mean stress or temperature. Further options are also provided to account for stress gradients and surface finishes.

Dang Van

Dang Van

Dang Van

Dang Van Multiaxial fatigue limit criterion is used to predict the endurance limit under complex loading situations.

Output is the safety factor. The program uses material parameters calculated from tensile and torsion tests. Account for manufacturing effects by using equivalent plastic strain in the unloaded component.

Safety Factor

Safety Factor

Safety Factor

Safety Factor Evaluate stress-based factors of safety and standard mean stress corrections or user-specified Haigh diagrams to assess durability.

This is widely used as a key design criterion for engine and powertrain components.

Seam Weld

Seam Weld

Seam Weld

Seam Weld Simplifies the process of setting up fatigue analysis of seam welds by intelligently identifying weld lines in the FEA Model.

Covers seam welded joints including fillet, overlap and laser welded joints. Stresses can either be taken directly from FEA models (shell or solid elements) or calculated from grid point forces or displacements at the weld. The approach is appropriate for weld toe, root and throat failures.

Spot Weld

Spot Weld

Spot Weld

Spot Weld Enables fatigue analysis of spot welds in thin sheets. Cross sectional forces and moments are used to calculate structural stress around the edge of the weld.

Life calculations are made around a spot weld at multiple angle increments and the total life reported includes the worst case. Python scripting enables modeling of other joining methods such as rivets or bolts.

Vibration Fatigue

Vibration Fatigue

Vibration Fatigue

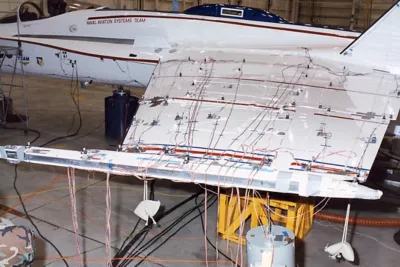

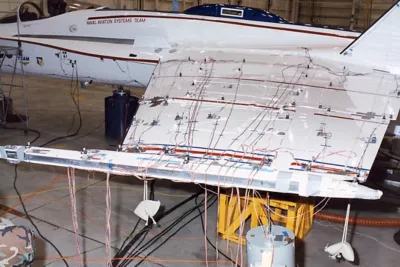

Vibration Fatigue The Vibration Fatigue option enables the simulation of vibration shaker tests driven by random (PSD), swept-sine, sine-dwell or sine-on-random loading.

It provides the capability to predict fatigue in the frequency domain and is more realistic and efficient than time-domain analysis for many applications with random loading, such as wind and wave loads.

Thermo-Mechanical Fatigue

Thermo-Mechanical Fatigue

Thermo-Mechanical Fatigue

Thermo-Mechanical Fatigue Components in high-temperature operating environments such as engine pistons, exhaust systems and manifolds can suffer from complex failure modes.

The Thermo-Mechanical Fatigue (TMF) option provides solvers for high-temperature fatigue and creep by using stress and temperature results from finite element simulations. TMF includes high temperature fatigue methods Chaboche and Chaboche Transient. Creep analysis methods include Larson-Miller and Chaboche creep.

Adhesive Bonds

Adhesive Bonds

Adhesive Bonds

Adhesive Bonds Enables fracture-mechanics-based method to assess which joints in the structure are most critically loaded.

The adhesive bonds option enables durability calculations on adhesive joints in metallic structures. Adhesive bonds are modeled with beam elements and grid point forces are used to determine line forces and moments at the edge of the glued flange. Approximate calculations of the strain energy release rate are made at the edge of the adhesive and, by comparison to the crack growth threshold, a safety factor is calculated.

Visioneering

Recent Events &

Webinars

Discover how engineering simulation is expanding across the entire product lifecycle.

Ansys Multiphysics

Conference

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Future Tech Expo 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Ansys Multiphysics

Conference

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Visioneering

Blogs & Trends

Discover how engineering simulation is expanding across the entire product lifecycle. engineering / product design analysis by modeling & simulation.

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Innovate

Breaking News & White Paper

Discover how engineering simulation is expanding across the entire product lifecycle.

Smart Strategies for Large Structural Simulations

One way to gauge the progress of engineering simulation software is through the lens of size. Engineers today routinely run structural simulations with a few million degrees of freedom, and the largest commercial structural simulations have topped even 100 million degrees of freedom.

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

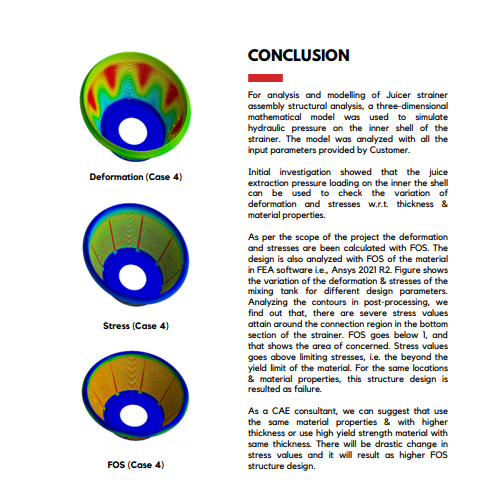

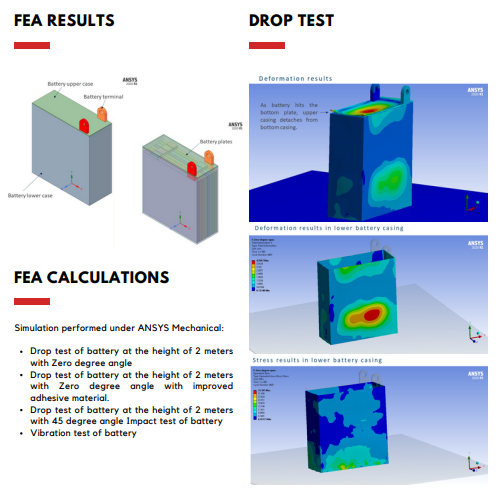

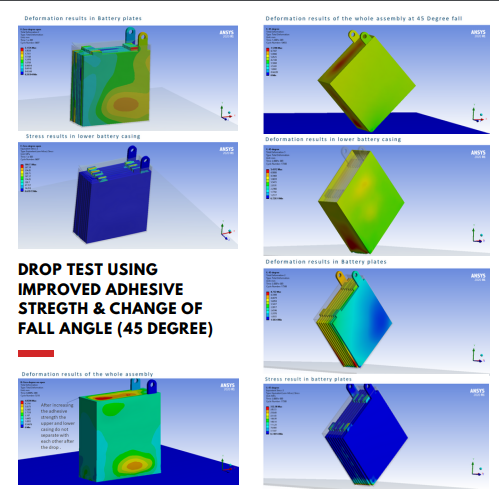

studies

case

Explore Case Studies

Qantur Technologies is a pioneer engineering simulations company based in Gurgaon –India. We provides expert Computer Aided Engineering – CAE consulting services for engineering / product design analysis by modeling & simulation.

Download Case Study

Transform Ideas into Reality—Explore Our Simulation Solutions Today!

Partner with Us to Revolutionize Engineering Excellence!

Testimonials

Customer Testimonials

Bengal Industries Pvt. Ltd

The ANSYS Mechanical training conducted by Qantur Technologies was highly informative and helped our engineers resolve critical challenges in contact modeling, meshing, and fatigue analysis. The sessions were well-coordinated, delivered on schedule, and supported with patient guidance by the trainer and account manager. We truly value Qantur’s expertise, professionalism, and post-sales support.

Bengal Industries Pvt. Ltd

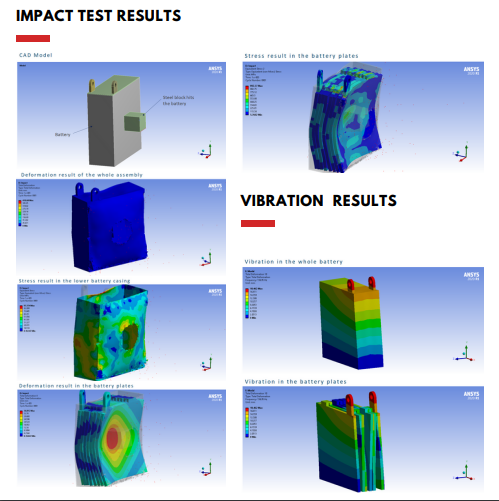

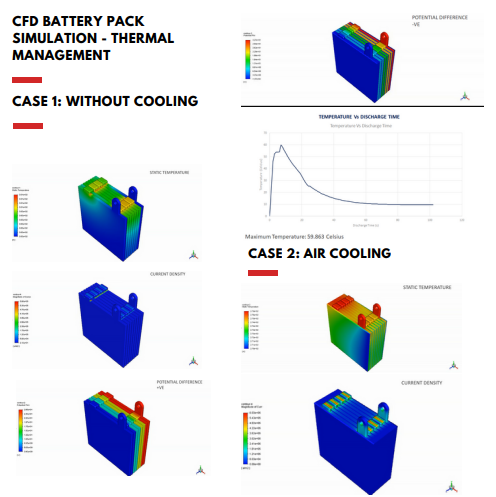

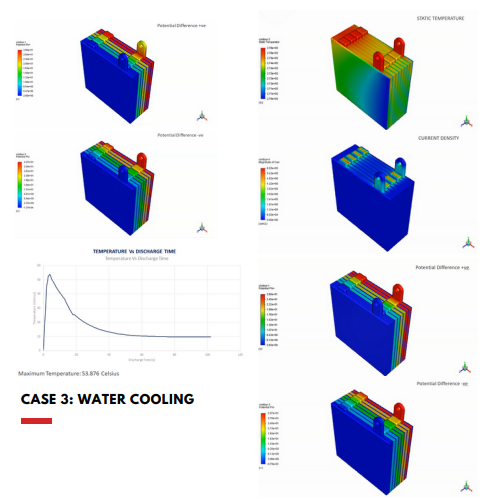

Bliss Anand Pvt. Ltd.

During our evaluation of CFD solutions, Qantur Technologies stood out for their technical expertise, reliability, and customer-focused approach. Their consulting projects achieved 98% accuracy compared to experimental values, instilling strong confidence in their capabilities. Based on this experience, we selected them as our preferred partner for ANSYS software, consulting, training, and support. We highly recommend their services to organizations with simulation requirements.

Bliss Anand Pvt. Ltd.

CUET, Department of Mechanical Engineering

We experienced significant value from Qantur Technologies’ expertise in ANSYS solutions, particularly in FEA and CFD consulting. Their skilled engineers provided insightful training on geometry, meshing, and modeling, which enhanced our students’ and faculty’s analytical skills. With exceptional support and patience from their trainers, we are pleased to recommend Qantur Technologies for ANSYS implementation, training, and advanced simulation services.

CUET, Department of Mechanical Engineering

Entecnia Consulting Pvt. Ltd.

Our collaboration with Qantur Technologies for ANSYS implementation and consulting has been outstanding. Their commitment, technical expertise, and timely support in FEA and CFD have added significant value to our engineering and R&D teams. The exclusive 15-day training session further enhanced our team’s analytical skills, and we truly appreciate their professionalism and ownership in managing the entire process seamlessly. We highly recommend Qantur Technologies for advanced CAE solutions.

Entecnia Consulting Pvt. Ltd.

Flovel Energy Pvt. Ltd.

Our experience with Qantur Technologies in implementing ANSYS HPC and CFD solutions has been remarkable. Their skilled engineers conducted in-depth training for our R&D team, equipping us with advanced methods to simulate hydro turbines and enhance component performance. Their reliable support, technical expertise, and resource assistance make them a trusted partner for ANSYS software, consulting, and training. We highly recommend Qantur Technologies for any ANSYS-related services.

Flovel Energy Pvt. Ltd.

Flovel Energy Pvt. Ltd.

We truly value the ANSYS SpaceClaim training conducted by Qantur Technologies at our R&D center. The course was tailored to our requirements, highly informative, and supported by hands-on workshops that enhanced our team’s modeling skills. Their application engineer was proactive, helpful, and ensured customization aligned with our needs. We look forward to engaging Qantur Technologies again for future application-based trainings.

Flovel Energy Pvt. Ltd.

IoTechWorld Avigation Pvt. Ltd.

At IoTechWorld, we develop advanced drones for agriculture, survey, and surveillance, and ANSYS Mechanical & CFD have been instrumental in optimizing our designs. Qantur Technologies supported us with the right resources, training, and technical expertise to address complex FEA & CFD challenges. Their team’s commitment and knowledge have empowered us to innovate faster and more effectively. We highly recommend Qantur Technologies for ANSYS implementation, consulting, and support.

IoTechWorld Avigation Pvt. Ltd.

Karman Drones Pvt. Ltd.

Our collaboration with Qantur Technologies for At Karman Drones, innovation drives our mission in AI-powered autonomous drones. Qantur Technologies has been a key partner in implementing ANSYS software, providing outstanding FEA & CFD expertise, consulting, and hands-on training. Their engineers have empowered our team with advanced simulation knowledge, improving design validation, performance optimization, and overall efficiency. We highly recommend Qantur Technologies for their exceptional support and technical proficiency.

Karman Drones Pvt. Ltd.

Mittal Electronics

At Mittal Electronics, innovation and R&D are at the heart of our product development. Partnering with Qantur Technologies for ANSYS FEA & CFD has been transformative—helping us accelerate design validation, optimize performance, and tackle complex engineering challenges with confidence. Their expert training, consulting, and quick response have greatly strengthened our engineering capabilities. We look forward to continued collaboration with Qantur Technologies.

Mittal Electronics

MV Electrosystems Pvt. Ltd.

At MV Electrosystems, innovation in rail transportation demands precision and reliability. Partnering with Qantur Technologies for ANSYS ICEPAK & Mechanical has significantly enhanced our ability to optimize product design, improve efficiency, and accelerate development. Their expert training, technical guidance, and hands-on support in FEA & CFD not only strengthened our engineering skills but also deepened our understanding of core physics. We truly value this collaboration and highly recommend Qantur Technologies for simulation-driven innovation.

MV Electrosystems Pvt. Ltd.

Nicotra India Pvt. Ltd.

At Nicotra India, precision in fan design is critical. Qantur Technologies has been a valuable partner, providing quick and responsive CFD support—both onsite and online—that helped us validate designs and solve complex meshing and model setup challenges. Their extensive training sessions empowered our R&D team with practical simulation expertise, strengthening our analytical and design capabilities. We are pleased with their services and highly recommend them for ANSYS implementation and technical support.

Nicotra India Pvt. Ltd.

NTF (India) Pvt. Ltd.

At NTF India, we rely on advanced engineering solutions to deliver world-class automotive components. Qantur Technologies has been a trusted partner, supporting us with ANSYS implementation and in-depth FEA analysis for our key projects. Their professionalism, technical expertise, and ability to deliver under challenging conditions have consistently exceeded our expectations. We highly value their commitment and look forward to continued collaboration on future product development initiatives.

NTF (India) Pvt. Ltd.

Onassis Auto Limited

At Onassis Auto, precision and reliability are at the core of our automotive components. With Qantur Technologies’ guidance in Ansys Mechanical, we have successfully enhanced our engineering capabilities, optimized transmission components, and improved efficiency. Their hands-on training, prompt support, and expertise in FEA have greatly empowered our R&D team. We are pleased to recommend Qantur Technologies for their outstanding technical services and commitment.

Onassis Auto Limited

P2P Analysis & Solutions

At P2P Analysis & Solutions, innovation is our core, and Qantur Technologies has been an invaluable partner in this journey. Their technical excellence in Ansys Mechanical and LS-DYNA, coupled with meticulous training and proactive support, has empowered our team to solve complex challenges with confidence. Their professionalism, collaborative approach, and customer-centric commitment make them a trusted long-term partner. We strongly recommend Qantur Technologies for any Ansys-related solutions and services.

P2P Analysis & Solutions

S&O Marintime

S&O Marintime