Industries

Oil & Gas Industry

Modeling and simulation are proven ways to address the high and unsustainable costs and time required for design and regulatory approval of increasingly complex healthcare solutions. This in silico approach maximizes patient safety while making healthcare more affordable.

Accelerating Innovation in Healthcare With In Silico Medicine

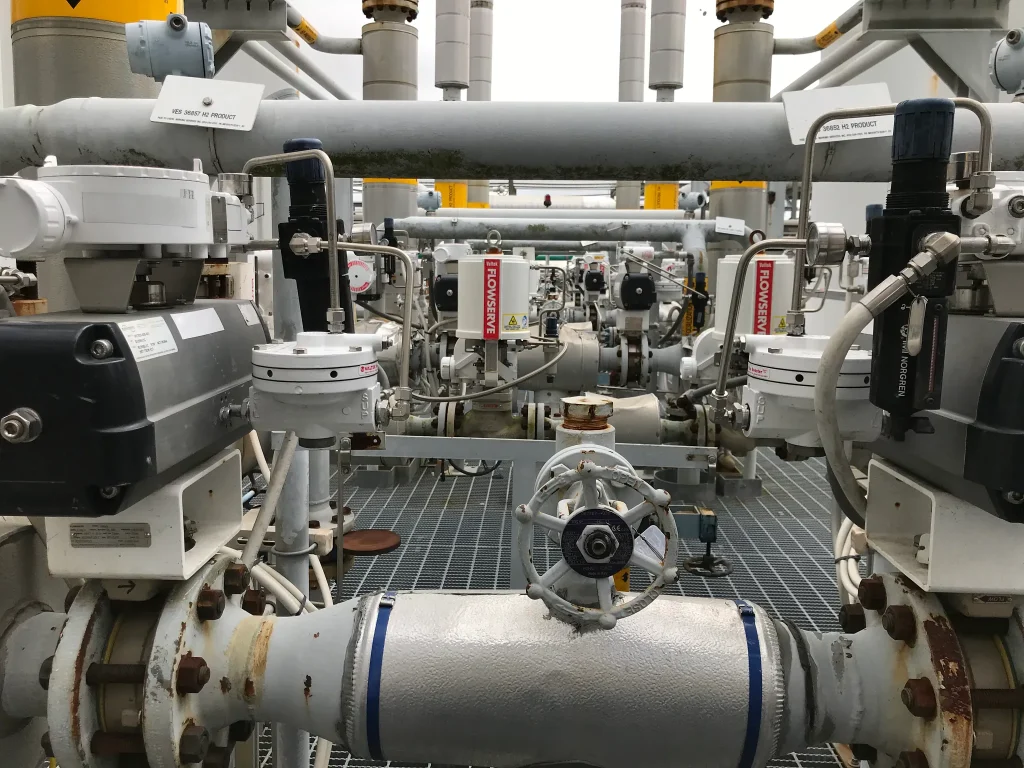

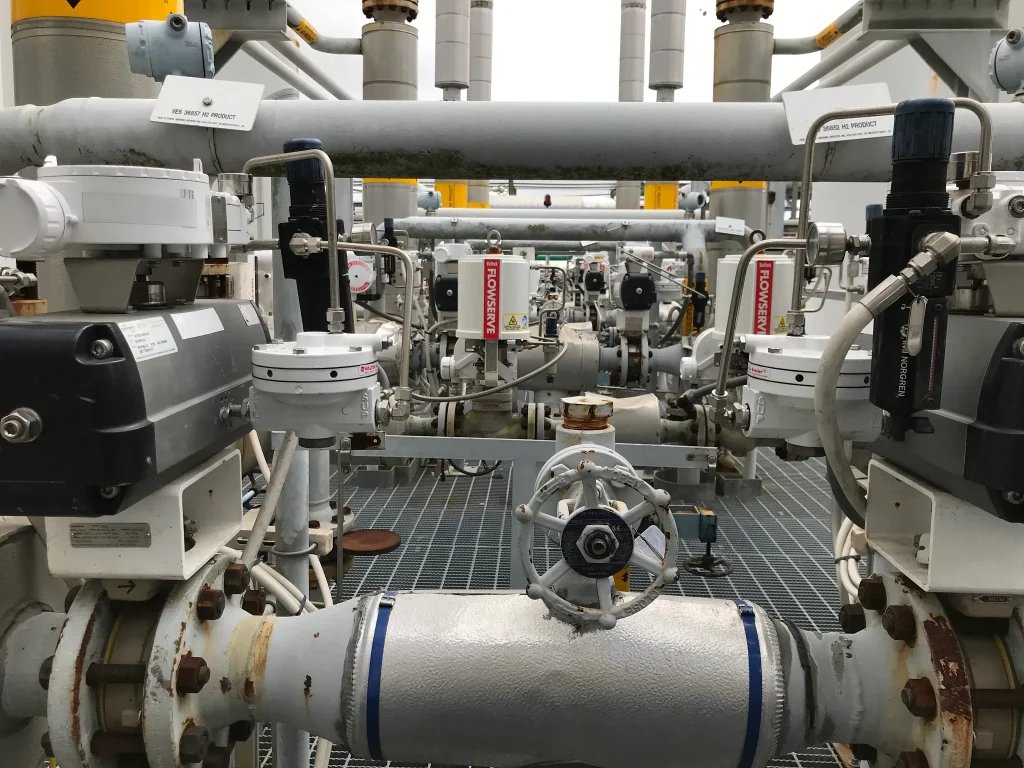

The oil and gas industry is essential for global energy production, encompassing the exploration, extraction, refining, transportation, and storage of petroleum products and natural gases. To ensure safe, efficient, and sustainable operations, various analyses are required, including structural integrity evaluations, fluid dynamics simulations, impact and blast simulations, and electromagnetic field design. Ansys provides a suite of tools to address these needs, like Ansys Mechanical for structural analysis of critical infrastructure, Ansys Fluent for fluid dynamics, heat transfer, corrosion and erosion simulations, Ansys CFX for turbomachinery design of pumps and compressors, Ansys Autodyn for impact and blast simulations, Ansys HFSS for electromagnetic simulations in equipment, and Ansys Granta for optimal material selection. These solutions help engineers design, optimize, and validate systems for the efficient and safe operation of oil, gas, and alternative energy infrastructure.

- Ansys Mechanical

- Ansys Fluent

- Ansys CFX

- Ansys Autodyn

- Ansys HFSS

- Ansys Granta

Subsurface Exploration and Drilling

ANSYS delivers robust simulation solutions tailored for the demanding challenges of subsurface exploration and drilling operations. These solutions help engineers analyze complex geological formations, optimize drilling performance, and ensure safety and environmental compliance in oil, gas, geothermal, and mining applications.

Structural analysis to ensure the durability of drilling equipment under extreme subsurface conditions.

Fluid dynamics to optimize mudflow and pressure control to enhance drilling performance.

Thermal analysis to prevent overheating, extending the lifespan of drilling components.

Vibration analysis to minimize the risk of fatigue failure of components, and reduce noise levels.

Component-Level Capabilities

ANSYS supports detailed simulation of drilling components such as drill bits, casing, mud pumps, and wellbore structures. Capabilities include geomechanical modeling, fluid flow and multiphase dynamics, thermal effects, vibration analysis, and rock-fracture prediction. This enables accurate prediction of drilling efficiency, equipment wear, well integrity, and risk mitigation in harsh subsurface environments.

Drill Bits

- Conduct structural analysis to evaluate the mechanical performance of components, ensuring efficient and reliable drilling.

- Perform fatigue analysis to assess durability and predict failure under repeated loading conditions in harsh environments.

Drill Pipes

- Perform structural analysis to assess the drill pipe's ability to withstand high torsional stresses and bending forces during drilling operations.

- Simulate fluid dynamics for efficient drilling fluid circulation, ensuring proper cooling of the drill bit.

Mud Pumps

- Simulate fluid dynamics to optimize the flow of drilling fluid, improving the effectiveness of the pump.

- Perform structural analysis to assess the pump’s durability and strength under extremely high pressures and cyclic loading.

Blowout Preventers (BOP)

- Analyze structural integrity and pressure resistance to ensure BOP components can withstand extreme pressure.

- Simulate seal performance to verify sealing capability and reliability under high-pressure conditions.

Relevant Ansys Software

ANSYS provides specialized tools such as Mechanical for structural and vibration analysis, Fluent for fluid dynamics, and Polyflow for complex flow behavior in drilling fluids. Coupled with multiphysics simulation platforms, these tools support comprehensive evaluation from drill string design to real-time drilling process optimization.

Pipeline Design

ANSYS provides advanced simulation solutions tailored for pipeline design and integrity management in industries such as oil & gas, water, chemicals, and energy. From structural analysis and fluid dynamics to thermal behavior and fatigue life prediction, ANSYS ensures safe, efficient, and regulation-compliant pipeline systems under diverse operational conditions and terrains.

Structural analysis to ensure the strength, reliability, and long-term durability of pipeline systems under various operational conditions.

Fluid dynamics analysis to optimize flow through pipelines, reducing energy losses and improving overall efficiency.

Thermal simulations to evaluate thermal expansion, stresses, and temperature effects on pipes and joints for enhanced safety and performance.

Corrosion and erosion simulations to predict material degradation, improve maintenance strategies, and extend pipeline lifespan.

Component-Level Capabilities

ANSYS enables detailed simulation of pipeline components including pipes, bends, flanges, valves, supports, and insulation systems. Capabilities include flow assurance (e.g., wax/hydrate formation), pressure drop analysis, thermal expansion, corrosion assessment, vibration response, and crack propagation. This allows engineers to optimize pipeline routing, material selection, and design for long-term operational safety and efficiency.

Pipe Segments

- Simulate fluid dynamics to optimize fluid flow through pipeline sections, minimizing energy losses

- Conduct structural analysis to predict and prevent leaks or ruptures caused by operational loads and external factors.

Fittings and Valves

- Perform fluid dynamics simulations to assess flow behavior through valves and fittings, and ensure precise flow control.

- Simulate corrosion and erosion to evaluate durability and resistance to wear, ensuring long-term reliability.

Pumps and Compressors

- Use fluid dynamics simulations to simulate flow around impeller blades, improving operational performance.

- Conduct structural analysis to verify the strength and reliability of components under varying pressure and load conditions.

Monitoring Systems

- Analyze signal integrity and electromagnetic performance of electronics and sensors for accurate and timely detection of leaks and system anomalies.

- Simulate and validate embedded software to ensure accurate real-time monitoring, data processing, and system diagnostics.

Relevant Ansys Software

ANSYS tools such as Fluent, Mechanical, CFX, and AQWA support multiphysics simulation of pipeline systems. Fluent and CFX handle internal fluid flow and pressure dynamics, while Mechanical simulates structural stress, vibration, and fatigue. AQWA enables offshore pipeline design by modeling wave, current, and seabed interactions—ensuring resilience in harsh marine environments.

Ansys Composite PrepPost

Models composite materials used in lightweight and corrosion-resistant pipelines or pipeline coatings, optimizing strength and durability.

Pressure Vessels and Tanks

ANSYS delivers high-fidelity simulation solutions for the design, analysis, and validation of pressure vessels and storage tanks across industries like oil & gas, chemical processing, power generation, and pharmaceuticals. By addressing critical concerns such as structural integrity, fatigue, buckling, thermal stress, and safety compliance, ANSYS ensures robust, cost-effective, and regulation-compliant designs.

Structural analysis to ensure the strength and reliability of pressure vessels and storage tanks under high-pressure conditions.

Thermal analysis to evaluate thermal expansion and stresses in the shell due to high temperatures of contained gases.

Vibration simulation to identify and minimize the risk of fatigue failure, preventing catastrophic outcomes.

Sloshing simulation to analyze the effects of liquid movement within the vessel, ensuring structural stability and safe operation.

Component-Level Capabilities

ANSYS supports simulation of key components such as cylindrical shells, domed heads, nozzles, flanges, stiffeners, internal baffles, and support structures. Capabilities include static and dynamic stress analysis, pressure-load response, thermal and seismic analysis, fatigue life estimation, weld strength assessment, and non-linear material modeling. This allows engineers to detect potential failure zones, optimize wall thickness, and verify compliance with ASME, EN, or API standards.

Storage Tanks

- Perform structural simulations to ensure storage tanks can withstand high internal pressures and maintain safety.

- Conduct corrosion simulations to assess the tank's resistance to long-term deterioration.

Pressure Vessels

- Assess the structural performance of vessels to ensure safe containment of gases under immense pressure.

- Perform thermal simulations to study thermal stresses, and their effect on the structural performance of the vessel and ensure safety.

Relief Valves

- Simulate fluid dynamics to assess the functionality of relief valves in controlling excessive pressure and preventing equipment failure.

- Perform stress analysis to ensure relief valves withstand long-term operational stresses and maintain reliable performance.

Mounts of Pressure Vessels

- Perform structural simulations to analyze the stresses in pressure vessel mounts under varying operational conditions.

- Conduct vibration and fatigue analysis to assess the durability and long-term performance of mounting systems.

Relevant Ansys Software

ANSYS Mechanical is the primary tool used for structural and thermal analysis of pressure vessels and tanks. Additional tools like Workbench, SpaceClaim, and DesignXplorer support geometry cleanup, parametric studies, and optimization workflows. Fluent or CFX can be integrated for internal fluid-structure interaction (FSI) simulations where pressure loading varies over time or location.

Ansys Composite PrepPost

Models composite materials used in lightweight, corrosion-resistant pressure vessels and tanks, optimizing for strength and durability.

LNG Facilities and Cryogenic Systems

ANSYS provides state-of-the-art simulation solutions for the design, analysis, and optimization of LNG (Liquefied Natural Gas) facilities and cryogenic systems. These tools help engineers address the unique thermal, structural, and fluid dynamics challenges posed by extremely low-temperature operations, ensuring safe, efficient, and reliable performance across storage, transportation, and regasification processes.

Thermal simulations to optimize insulation and minimize heat ingress in cryogenic storage and transport systems.

Fluid dynamics to ensure efficient liquefaction, regasification, and transport processes.

Structural analysis to assess the safety and durability of LNG storage tanks and pipelines under cryogenic conditions.

Vibration analysis to prevent fatigue failure in pipelines and equipment operating under cryogenic temperatures.

Sloshing simulations to evaluate the impact of liquid motion within storage tanks during transport, ensuring structural stability.

Component-Level Capabilities

ANSYS supports detailed simulation of LNG components including cryogenic tanks, heat exchangers, piping systems, pumps, vaporizers, insulation materials, and structural supports. Capabilities include thermal contraction analysis, two-phase flow modeling, boil-off gas (BOG) prediction, fracture mechanics at cryogenic temperatures, and structural integrity under extreme thermal gradients. These simulations help reduce energy losses, improve safety, and extend asset life.

Cryogenic Storage Tanks

- Perform structural analysis to ensure tank stability under significant thermal stresses caused by cryogenic temperatures.

- Simulate sloshing to evaluate internal liquid dynamics and their effect on tank safety during transport.

Liquefaction Units

- Simulate thermal analysis to optimize cooling processes and ensure energy-efficient operation.

- Analyze fluid dynamics to ensure the efficient flow of natural gas and refrigerants through the system.

Transport Pipelines

- Simulate fluid dynamics to optimize gas and liquid flow, reducing energy losses during transport.

- Conduct thermal analysis to evaluate insulation performance, ensuring minimal heat ingress over long distances.

Heat Exchangers

- Perform thermal simulations to optimize the heat transfer efficiency for liquefaction and regasification processes.

- Conduct corrosion and erosion simulations to enhance the operational life of tubes and other components of heat exchangers.

Relevant Ansys Software

ANSYS tools such as Fluent (for cryogenic fluid flow), Mechanical (for structural and thermal analysis), Icepak (for thermal management), and DesignModeler/SpaceClaim (for geometry preparation) are extensively used in LNG system design. These tools enable coupled fluid-thermal-structural simulations that reflect real-world LNG operating conditions, including rapid cooldown and heat transfer across insulation layers.

Ansys Composite PrepPost

Models composite materials used in cryogenic pipelines or LNG systems for lightweight, durable, and corrosion-resistant components.

Ansys Additive Suite

Simulates additive manufacturing processes for creating customized cryogenic system components, such as specialized nozzles and lightweight support structures.

Ansys Chemkin-Pro

Models combustion processes in LNG flaring systems, optimizing energy efficiency and reducing emissions in LNG facilities.

Refineries

ANSYS provides comprehensive simulation solutions tailored for the design, optimization, and operational safety of oil refineries. By enabling detailed analysis of fluid dynamics, heat transfer, structural integrity, and equipment interactions, ANSYS helps refineries improve throughput, reduce emissions, and maintain regulatory compliance across critical processes such as distillation, cracking, and chemical treatment.

Fluid dynamics simulations to optimize refining processes, improve flow efficiency, and reduce energy consumption across equipment and pipelines.

Structural simulations to ensure refinery equipment, such as vessels and piping, can withstand operational stresses.

Thermal analysis to assess thermal stresses and optimize heat transfer across systems, minimizing energy losses and enhancing process efficiency.

Corrosion and erosion simulations to evaluate the influence of working fluids on refinery equipment, ensuring longevity.

Component-Level Capabilities

ANSYS supports simulation of key refinery equipment including distillation columns, heat exchangers, reactors, furnaces, compressors, pumps, storage tanks, and piping networks. Capabilities include multi-phase flow modeling, thermal stress analysis, fouling prediction, vibration and fatigue analysis, corrosion assessment, and dynamic pressure fluctuations. These simulations help optimize process efficiency, minimize downtime, and extend equipment lifespan.

Distillation Columns

- Simulate fluid dynamics to optimize distillation efficiency, including phase transitions and flow behaviour.

- Perform structural analysis to assess the ability of distillation column components to handle thermal and mechanical stresses.

Reactors

- Simulate combustion reactions and optimize parameters for efficient burning of fuel.

- Perform thermal analysis to evaluate thermal expansion and stresses developed due to exothermic reactions in reactors.

Heat Exchangers

- Perform thermal simulations to optimize fluid flow and improve heat exchange efficiency.

- Conduct thermo-structural analysis to evaluate the durability of heat exchanger components under continuous thermal cycling and mechanical stress.

Pumps and Compressors

- Simulate fluid dynamics to ensure proper flow of fluid around the blades of the impeller, thereby improving efficiency.

- Perform structural and vibrational analysis to assess pump and compressor housing for long-term reliability and resistance to fatigue.

Storage Tanks

- Perform structural analysis to ensure storage tanks can withstand high internal pressures and external factors like seismic loads.

- Conduct thermal simulation to assess thermal expansion and stresses, and performance of heat insulation materials.

Relevant Ansys Software

ANSYS Fluent and CFX are widely used for computational fluid dynamics (CFD) to model complex flow and heat transfer in process equipment. ANSYS Mechanical supports structural and fatigue analysis of vessels and piping. Tools like Chemkin-Pro enable chemical kinetics modeling for combustion and catalytic reactions, while Workbench provides an integrated environment for multiphysics simulations across refinery systems.

Ansys Composite PrepPost

Models composite materials for lightweight and corrosion-resistant components used in refinery systems.

interested in our Product or Solution

Still have a Question?

FAQ

How can ANSYS improve the performance of my automotive designs?

ANSYS allows for detailed simulation and analysis, enabling optimization of factors like aerodynamics, structural integrity, and thermal management. This leads to better performing and more efficient vehicles.

Can ANSYS help reduce the time and cost of automotive development?

Yes, by providing accurate virtual testing, ANSYS reduces the need for physical prototypes and testing cycles. This leads to faster development times and significant cost savings.

What types of automotive simulations can ANSYS perform?

ANSYS can handle a wide range of simulations, including crash analysis, fluid dynamics for aerodynamics, thermal analysis for engine cooling, and NVH analysis for noise reduction.

Is ANSYS compatible with my existing CAD software?

ANSYS is designed to integrate with most standard CAD software, ensuring a smooth workflow. We support common file formats for easy data transfer and interoperability

Transform Ideas into Reality—Explore Our Simulation Solutions Today!

Partner with Us to Revolutionize Engineering Excellence!

Testimonials

Customer Testimonials

Bengal Industries Pvt. Ltd

The ANSYS Mechanical training conducted by Qantur Technologies was highly informative and helped our engineers resolve critical challenges in contact modeling, meshing, and fatigue analysis. The sessions were well-coordinated, delivered on schedule, and supported with patient guidance by the trainer and account manager. We truly value Qantur’s expertise, professionalism, and post-sales support.

Bengal Industries Pvt. Ltd

Bliss Anand Pvt. Ltd.

During our evaluation of CFD solutions, Qantur Technologies stood out for their technical expertise, reliability, and customer-focused approach. Their consulting projects achieved 98% accuracy compared to experimental values, instilling strong confidence in their capabilities. Based on this experience, we selected them as our preferred partner for ANSYS software, consulting, training, and support. We highly recommend their services to organizations with simulation requirements.

Bliss Anand Pvt. Ltd.

CUET, Department of Mechanical Engineering

We experienced significant value from Qantur Technologies’ expertise in ANSYS solutions, particularly in FEA and CFD consulting. Their skilled engineers provided insightful training on geometry, meshing, and modeling, which enhanced our students’ and faculty’s analytical skills. With exceptional support and patience from their trainers, we are pleased to recommend Qantur Technologies for ANSYS implementation, training, and advanced simulation services.

CUET, Department of Mechanical Engineering

Entecnia Consulting Pvt. Ltd.

Our collaboration with Qantur Technologies for ANSYS implementation and consulting has been outstanding. Their commitment, technical expertise, and timely support in FEA and CFD have added significant value to our engineering and R&D teams. The exclusive 15-day training session further enhanced our team’s analytical skills, and we truly appreciate their professionalism and ownership in managing the entire process seamlessly. We highly recommend Qantur Technologies for advanced CAE solutions.

Entecnia Consulting Pvt. Ltd.

Flovel Energy Pvt. Ltd.

Our experience with Qantur Technologies in implementing ANSYS HPC and CFD solutions has been remarkable. Their skilled engineers conducted in-depth training for our R&D team, equipping us with advanced methods to simulate hydro turbines and enhance component performance. Their reliable support, technical expertise, and resource assistance make them a trusted partner for ANSYS software, consulting, and training. We highly recommend Qantur Technologies for any ANSYS-related services.

Flovel Energy Pvt. Ltd.

Flovel Energy Pvt. Ltd.

We truly value the ANSYS SpaceClaim training conducted by Qantur Technologies at our R&D center. The course was tailored to our requirements, highly informative, and supported by hands-on workshops that enhanced our team’s modeling skills. Their application engineer was proactive, helpful, and ensured customization aligned with our needs. We look forward to engaging Qantur Technologies again for future application-based trainings.

Flovel Energy Pvt. Ltd.

IoTechWorld Avigation Pvt. Ltd.

At IoTechWorld, we develop advanced drones for agriculture, survey, and surveillance, and ANSYS Mechanical & CFD have been instrumental in optimizing our designs. Qantur Technologies supported us with the right resources, training, and technical expertise to address complex FEA & CFD challenges. Their team’s commitment and knowledge have empowered us to innovate faster and more effectively. We highly recommend Qantur Technologies for ANSYS implementation, consulting, and support.

IoTechWorld Avigation Pvt. Ltd.

Karman Drones Pvt. Ltd.

Our collaboration with Qantur Technologies for At Karman Drones, innovation drives our mission in AI-powered autonomous drones. Qantur Technologies has been a key partner in implementing ANSYS software, providing outstanding FEA & CFD expertise, consulting, and hands-on training. Their engineers have empowered our team with advanced simulation knowledge, improving design validation, performance optimization, and overall efficiency. We highly recommend Qantur Technologies for their exceptional support and technical proficiency.

Karman Drones Pvt. Ltd.

Mittal Electronics

At Mittal Electronics, innovation and R&D are at the heart of our product development. Partnering with Qantur Technologies for ANSYS FEA & CFD has been transformative—helping us accelerate design validation, optimize performance, and tackle complex engineering challenges with confidence. Their expert training, consulting, and quick response have greatly strengthened our engineering capabilities. We look forward to continued collaboration with Qantur Technologies.

Mittal Electronics

MV Electrosystems Pvt. Ltd.

At MV Electrosystems, innovation in rail transportation demands precision and reliability. Partnering with Qantur Technologies for ANSYS ICEPAK & Mechanical has significantly enhanced our ability to optimize product design, improve efficiency, and accelerate development. Their expert training, technical guidance, and hands-on support in FEA & CFD not only strengthened our engineering skills but also deepened our understanding of core physics. We truly value this collaboration and highly recommend Qantur Technologies for simulation-driven innovation.

MV Electrosystems Pvt. Ltd.

Nicotra India Pvt. Ltd.

At Nicotra India, precision in fan design is critical. Qantur Technologies has been a valuable partner, providing quick and responsive CFD support—both onsite and online—that helped us validate designs and solve complex meshing and model setup challenges. Their extensive training sessions empowered our R&D team with practical simulation expertise, strengthening our analytical and design capabilities. We are pleased with their services and highly recommend them for ANSYS implementation and technical support.

Nicotra India Pvt. Ltd.

NTF (India) Pvt. Ltd.

At NTF India, we rely on advanced engineering solutions to deliver world-class automotive components. Qantur Technologies has been a trusted partner, supporting us with ANSYS implementation and in-depth FEA analysis for our key projects. Their professionalism, technical expertise, and ability to deliver under challenging conditions have consistently exceeded our expectations. We highly value their commitment and look forward to continued collaboration on future product development initiatives.

NTF (India) Pvt. Ltd.

Onassis Auto Limited

At Onassis Auto, precision and reliability are at the core of our automotive components. With Qantur Technologies’ guidance in Ansys Mechanical, we have successfully enhanced our engineering capabilities, optimized transmission components, and improved efficiency. Their hands-on training, prompt support, and expertise in FEA have greatly empowered our R&D team. We are pleased to recommend Qantur Technologies for their outstanding technical services and commitment.

Onassis Auto Limited

P2P Analysis & Solutions

At P2P Analysis & Solutions, innovation is our core, and Qantur Technologies has been an invaluable partner in this journey. Their technical excellence in Ansys Mechanical and LS-DYNA, coupled with meticulous training and proactive support, has empowered our team to solve complex challenges with confidence. Their professionalism, collaborative approach, and customer-centric commitment make them a trusted long-term partner. We strongly recommend Qantur Technologies for any Ansys-related solutions and services.

P2P Analysis & Solutions

S&O Marintime

S&O Marintime