Products

Ansys SpaceClaim 3D Modeling Software

SpaceClaim offers lightweight 3D modeling for fast, simple answers

Ansys SpaceClaim is the perfect modeling solution for engineers who want access to 3D answers but don’t have the time or inclination to learn complex traditional CAD systems. It provides you with tools to accelerate geometry preparation and get to simulation sooner while eliminating delays between design teams.

- Edit, repair and create any geometry

- De-feature CAD models, extract fluid domains or simplify models for simulation

- Leverage scan data to reverse engineer new parts

- Prepare models for manufacturing steps and maximize machining time

- STL prep for 3D printing

- Create, import, or repair sheet metal designs

Features

Quick Specs

Reduce simulations prep time and create 3D models quickly with Ansys SpaceClaim. These tools free designers and analysts to focus on simulation results by accelerating the geometry creation process.

Still have a question?

Design and Concept Modeling

Reverse Engineering

Model Prep for Simulation

Scan-to-CAD

3D Printing

Sheet Metal

Model Prep for Manufacturing

Motion Dynamics

Modeling for CAE

Jig and Fixture Design

STL Prep for 3D Printing

Additive Manufacturing

Capabilities

Ansys SpaceClaim 3D Modeling Software Quickly Solves Geometry Problems

Ansys SpaceClaim lets engineers easily leverage 3D modeling to explore ideas and solve problems. 3D models can be simplified for analysis in a fraction of the time it takes with traditional CAD. From reverse engineering to model prep for sheet metal manufacturing, easy-to-use SpaceClaim software streamlines the model creation process.

Capabilities

Key Features

Simplify and accelerate model creation with a range of SpaceClaim modeling software capabilities:

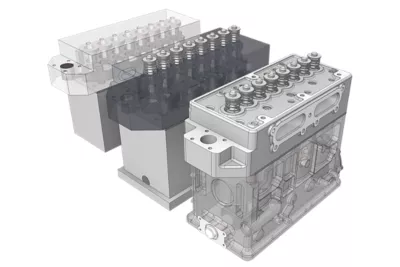

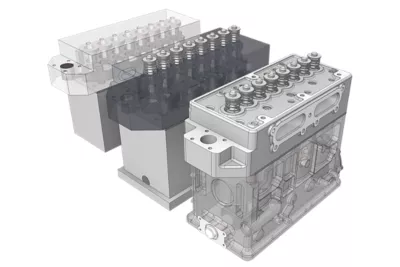

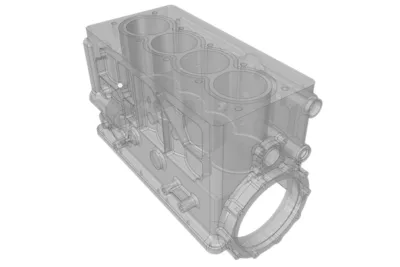

Model Prep for Simulation

Model Prep for Simulation

Model Prep for Simulation

Model Prep for Simulation Simplify models in minutes instead of hours. Quickly modify, optimize and parameterize any CAD file to reduce mesh complexity and speed up simulation solve time.

Let the power of SpaceClaim streamline workflows to reduce model pre-processing time from weeks or days to hours or minutes, all while eliminating the need to outsource CAD modifications. Whether you’re modifying existing geometry or creating simplified representations, SpaceClaim eliminates geometry bottlenecks to let engineers focus on physics. Simulation-driven product development allows parameterizing of any model and includes bidirectional linkage to Ansys Workbench for seamless integration of geometry. This allows for fast, bottleneck-free answers in 3D.

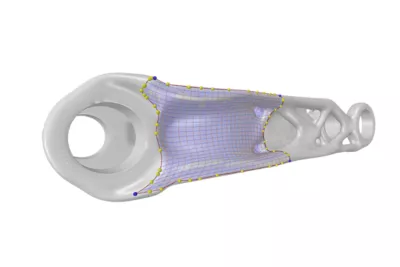

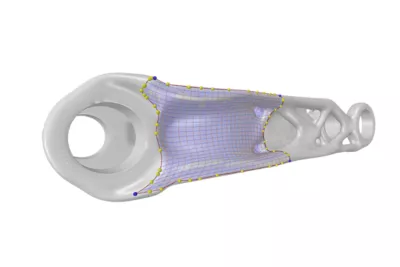

Reverse Engineering

Reverse Engineering

Reverse Engineering

Reverse Engineering Use intuitive and powerful tools to autosurface simple or complex mesh data, build intricate parts or recreate fixtures quickly and efficiently.

Power, ease and flexibility combine to make SpaceClaim a reverse engineering tool that, regardless of scan integrity, can take any STL file and covert it to CAD format. Skin Surface offers a powerful method for autosurfacing solid geometry from prismatic or organic shapes, enabling you to reconstruct surface data around scans of complex shapes, including living organisms.

Design and Concept Modeling

Design and Concept Modeling

Design and Concept Modeling

Design and Concept Modeling Create parts, assemblies and drawings. Open, repair and edit any CAD file. SpaceClaim’s direct modeling technology is faster, easier and more flexible than any other 3D modeling tool.

Design the way you think. SpaceClaim’s fully functioning CAD tool is powerful enough for rapid concept modeling but simple enough to create detailed parts, assemblies and drawings. A simple 2D-to-3D-geometry conversion tool streamlines the work process, using common workflows to generate 3D-ready data from a variety of file types. Let the software free you to focus on creativity, ideas and productivity.

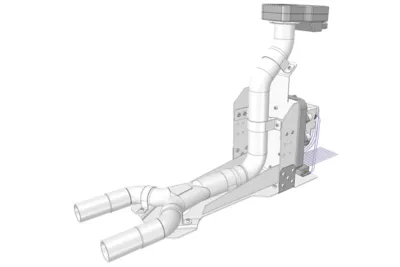

Model Prep for Manufacturing

Model Prep for Manufacturing

Model Prep for Manufacturing

Model Prep for Manufacturing Prepare models for manufacturing steps and maximize machining time. Edit any CAD file, repair corrupt or difficult CAD files and design jigs and fixtures faster than ever before.

The flexibility enjoyed in SpaceClaim reduces the challenges of prepping models for manufacturing. Open, edit and prepare parts from any CAD system while easily converting multiple file types into 3D data for next-step machining. The automated repair tools can turn corrupt or incomplete data into usable surfaces or solids, letting engineers focus on toolpath creation. SpaceClaim will automatically heal disjointed surfaces and repair holes and gaps. Rapidly extract geometry for fixturing or tooling of any objects, all while integrating and leveraging partnerships with other libraries and systems.

Sheet Metal Design and Manufacturing

Sheet Metal Design and Manufacturing

Sheet Metal Design and Manufacturing

Sheet Metal Design and Manufacturing Complete sheet metal jobs quickly while minimizing downtime on the shop floor. Design enclosures and convert 3D files to unfolded layouts and import and repair unfoldable sheet metal designs.

SpaceClaim gives engineers the flexibility to work with any CAD data to create, edit and prepare models for high-precision sheet metal fabrication. No other tool is easier to use and does a better job editing geometry, cleaning up corrupt or difficult CAD data and delivering high-quality sheet metal functionality. You can automatically unfold virtually any sheet metal parts and export them while simultaneously viewing and editing folded and unfolded models. In SpaceClaim, you can adjust thickness, bend allowance and material properties on any model and customize a form library along the way. With live design feedback, optimization is made simple.

3D Printing

3D Printing

3D Printing

3D Printing Make any 3D file print-ready. Analyze and repair dirty or corrupt faceted data or quickly create, edit and prepare optimized models for 3D printing.

Speed up your 3D printing with SpaceClaim. The STL prep module — a faceted data toolkit — lets you work directly with STL files, as well as a bounty of automated prep tools to repair a file and get it ready for a printable model, all regardless of imperfections. Edit a collection of facets to alter the form, giving you freedom for rapid changes. Optimization tools smooth and reduce noise to balance the strength and weight ratio while minimizing material consumption. The analytical tools help ensure your model has adequate wall thickness and critical-area protection to efficiently and confidently create.

Visioneering

Recent Events & Webinars

Discover how engineering simulation is expanding across the entire product lifecycle.

Ansys Multiphysics

Conference

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Future Tech Expo 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Ansys Multiphysics

Conference

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Blog

Innovative Simulations

Summit 2025

Join us on Saturday, June 10th, 2023, at 3 PM. The event will take place at Riverside Park, 123 River Lane, Springfield.

Visioneering

Blogs & Trends

Discover how engineering simulation is expanding across the entire product lifecycle. engineering / product design analysis by modeling & simulation.

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Ansys Multiphysics Conferences

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Innovative Simulations Summit 2024

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum

Innovate

Breaking News & White Paper

Discover how engineering simulation is expanding across the entire product lifecycle.

Smart Strategies for Large Structural Simulations

One way to gauge the progress of engineering simulation software is through the lens of size. Engineers today routinely run structural simulations with a few million degrees of freedom, and the largest commercial structural simulations have topped even 100 million degrees of freedom.

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

Introduction Mi tincidunt elit, id quisque ligula ac diam, amet. Vel etiam suspendisse morbi eleifend faucibus eget vestibulum felis. Dictum quis montes, sit sit. Tellus

studies

Case

Explore Case Studies

Qantur Technologies is a pioneer engineering simulations company based in Gurgaon –India. We provides expert Computer Aided Engineering – CAE consulting services for engineering / product design analysis by modeling & simulation.

Download Case Study

Transform Ideas into Reality—Explore Our Simulation Solutions Today!

Partner with Us to Revolutionize Engineering Excellence!

Testimonials

Customer Testimonials

Bengal Industries Pvt. Ltd

The ANSYS Mechanical training conducted by Qantur Technologies was highly informative and helped our engineers resolve critical challenges in contact modeling, meshing, and fatigue analysis. The sessions were well-coordinated, delivered on schedule, and supported with patient guidance by the trainer and account manager. We truly value Qantur’s expertise, professionalism, and post-sales support.

Bengal Industries Pvt. Ltd

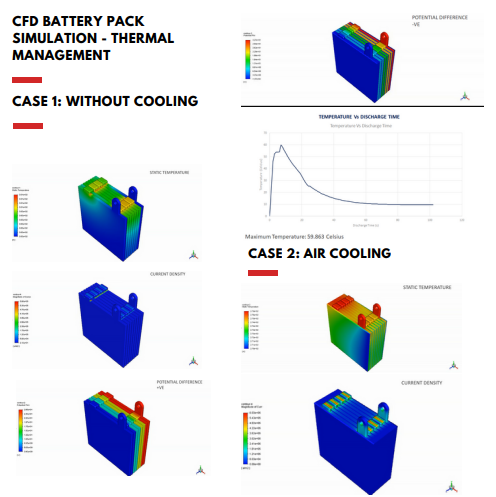

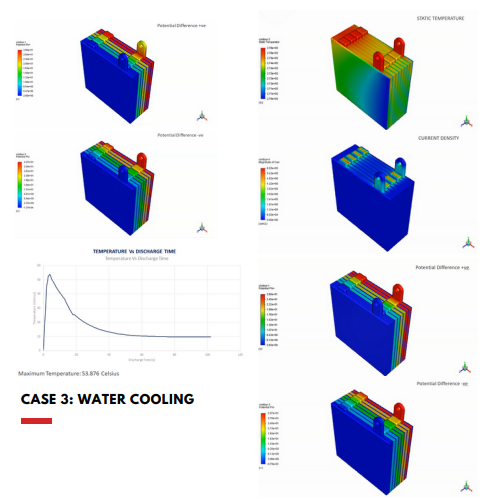

Bliss Anand Pvt. Ltd.

During our evaluation of CFD solutions, Qantur Technologies stood out for their technical expertise, reliability, and customer-focused approach. Their consulting projects achieved 98% accuracy compared to experimental values, instilling strong confidence in their capabilities. Based on this experience, we selected them as our preferred partner for ANSYS software, consulting, training, and support. We highly recommend their services to organizations with simulation requirements.

Bliss Anand Pvt. Ltd.

CUET, Department of Mechanical Engineering

We experienced significant value from Qantur Technologies’ expertise in ANSYS solutions, particularly in FEA and CFD consulting. Their skilled engineers provided insightful training on geometry, meshing, and modeling, which enhanced our students’ and faculty’s analytical skills. With exceptional support and patience from their trainers, we are pleased to recommend Qantur Technologies for ANSYS implementation, training, and advanced simulation services.

CUET, Department of Mechanical Engineering

Entecnia Consulting Pvt. Ltd.

Our collaboration with Qantur Technologies for ANSYS implementation and consulting has been outstanding. Their commitment, technical expertise, and timely support in FEA and CFD have added significant value to our engineering and R&D teams. The exclusive 15-day training session further enhanced our team’s analytical skills, and we truly appreciate their professionalism and ownership in managing the entire process seamlessly. We highly recommend Qantur Technologies for advanced CAE solutions.

Entecnia Consulting Pvt. Ltd.

Flovel Energy Pvt. Ltd.

Our experience with Qantur Technologies in implementing ANSYS HPC and CFD solutions has been remarkable. Their skilled engineers conducted in-depth training for our R&D team, equipping us with advanced methods to simulate hydro turbines and enhance component performance. Their reliable support, technical expertise, and resource assistance make them a trusted partner for ANSYS software, consulting, and training. We highly recommend Qantur Technologies for any ANSYS-related services.

Flovel Energy Pvt. Ltd.

Flovel Energy Pvt. Ltd.

We truly value the ANSYS SpaceClaim training conducted by Qantur Technologies at our R&D center. The course was tailored to our requirements, highly informative, and supported by hands-on workshops that enhanced our team’s modeling skills. Their application engineer was proactive, helpful, and ensured customization aligned with our needs. We look forward to engaging Qantur Technologies again for future application-based trainings.

Flovel Energy Pvt. Ltd.

IoTechWorld Avigation Pvt. Ltd.

At IoTechWorld, we develop advanced drones for agriculture, survey, and surveillance, and ANSYS Mechanical & CFD have been instrumental in optimizing our designs. Qantur Technologies supported us with the right resources, training, and technical expertise to address complex FEA & CFD challenges. Their team’s commitment and knowledge have empowered us to innovate faster and more effectively. We highly recommend Qantur Technologies for ANSYS implementation, consulting, and support.

IoTechWorld Avigation Pvt. Ltd.

Karman Drones Pvt. Ltd.

Our collaboration with Qantur Technologies for At Karman Drones, innovation drives our mission in AI-powered autonomous drones. Qantur Technologies has been a key partner in implementing ANSYS software, providing outstanding FEA & CFD expertise, consulting, and hands-on training. Their engineers have empowered our team with advanced simulation knowledge, improving design validation, performance optimization, and overall efficiency. We highly recommend Qantur Technologies for their exceptional support and technical proficiency.

Karman Drones Pvt. Ltd.

Mittal Electronics

At Mittal Electronics, innovation and R&D are at the heart of our product development. Partnering with Qantur Technologies for ANSYS FEA & CFD has been transformative—helping us accelerate design validation, optimize performance, and tackle complex engineering challenges with confidence. Their expert training, consulting, and quick response have greatly strengthened our engineering capabilities. We look forward to continued collaboration with Qantur Technologies.

Mittal Electronics

MV Electrosystems Pvt. Ltd.

At MV Electrosystems, innovation in rail transportation demands precision and reliability. Partnering with Qantur Technologies for ANSYS ICEPAK & Mechanical has significantly enhanced our ability to optimize product design, improve efficiency, and accelerate development. Their expert training, technical guidance, and hands-on support in FEA & CFD not only strengthened our engineering skills but also deepened our understanding of core physics. We truly value this collaboration and highly recommend Qantur Technologies for simulation-driven innovation.

MV Electrosystems Pvt. Ltd.

Nicotra India Pvt. Ltd.

At Nicotra India, precision in fan design is critical. Qantur Technologies has been a valuable partner, providing quick and responsive CFD support—both onsite and online—that helped us validate designs and solve complex meshing and model setup challenges. Their extensive training sessions empowered our R&D team with practical simulation expertise, strengthening our analytical and design capabilities. We are pleased with their services and highly recommend them for ANSYS implementation and technical support.

Nicotra India Pvt. Ltd.

NTF (India) Pvt. Ltd.

At NTF India, we rely on advanced engineering solutions to deliver world-class automotive components. Qantur Technologies has been a trusted partner, supporting us with ANSYS implementation and in-depth FEA analysis for our key projects. Their professionalism, technical expertise, and ability to deliver under challenging conditions have consistently exceeded our expectations. We highly value their commitment and look forward to continued collaboration on future product development initiatives.

NTF (India) Pvt. Ltd.

Onassis Auto Limited

At Onassis Auto, precision and reliability are at the core of our automotive components. With Qantur Technologies’ guidance in Ansys Mechanical, we have successfully enhanced our engineering capabilities, optimized transmission components, and improved efficiency. Their hands-on training, prompt support, and expertise in FEA have greatly empowered our R&D team. We are pleased to recommend Qantur Technologies for their outstanding technical services and commitment.

Onassis Auto Limited

P2P Analysis & Solutions

At P2P Analysis & Solutions, innovation is our core, and Qantur Technologies has been an invaluable partner in this journey. Their technical excellence in Ansys Mechanical and LS-DYNA, coupled with meticulous training and proactive support, has empowered our team to solve complex challenges with confidence. Their professionalism, collaborative approach, and customer-centric commitment make them a trusted long-term partner. We strongly recommend Qantur Technologies for any Ansys-related solutions and services.

P2P Analysis & Solutions

S&O Marintime

S&O Marintime